Defense & Systems

Driving defense innovation

in Korea

GE Aerospace is uniquely positioned to work closely with Korea and support the nation’s defense sector. Over the past 60 years, GE Aerospace has provided innovative, reliable and high-performance engines, and comprehensive engine maintenance services, for Korean military aircraft and naval ships.

More than 1,500 GE Aerospace engines have been chosen for Korea’s military aircraft and naval ships, making it the largest fleet of defense engines in operation outside the United States.

GE Aerospace has supplied the ROK (Republic of Korea) Navy with 163 marine gas turbines for 95 ships, including the Yoon Youngha-class patrol vessel, Ulsan-class frigate, and Aegis Destroyer. With our in-country partner, we co-manufacture the engine components for the ROK’s naval and industrial gas turbines, and assemble, test, and provide service support to GE Aerospace naval engines in Korea.

More than 1,500 GE Aerospace engines have been chosen for Korea’s military aircraft and naval ships, making it the largest fleet of defense engines in operation outside the United States.

GE Aerospace has supplied the ROK (Republic of Korea) Navy with 163 marine gas turbines for 95 ships, including the Yoon Youngha-class patrol vessel, Ulsan-class frigate, and Aegis Destroyer. With our in-country partner, we co-manufacture the engine components for the ROK’s naval and industrial gas turbines, and assemble, test, and provide service support to GE Aerospace naval engines in Korea.

Growing together: Our shared vision

GE Aerospace is a committed long-term partner to Korea's aviation industry. By working closely with Korean companies and customers to deliver world-class engines and advanced technologies, we help power the nation's defense capabilities.

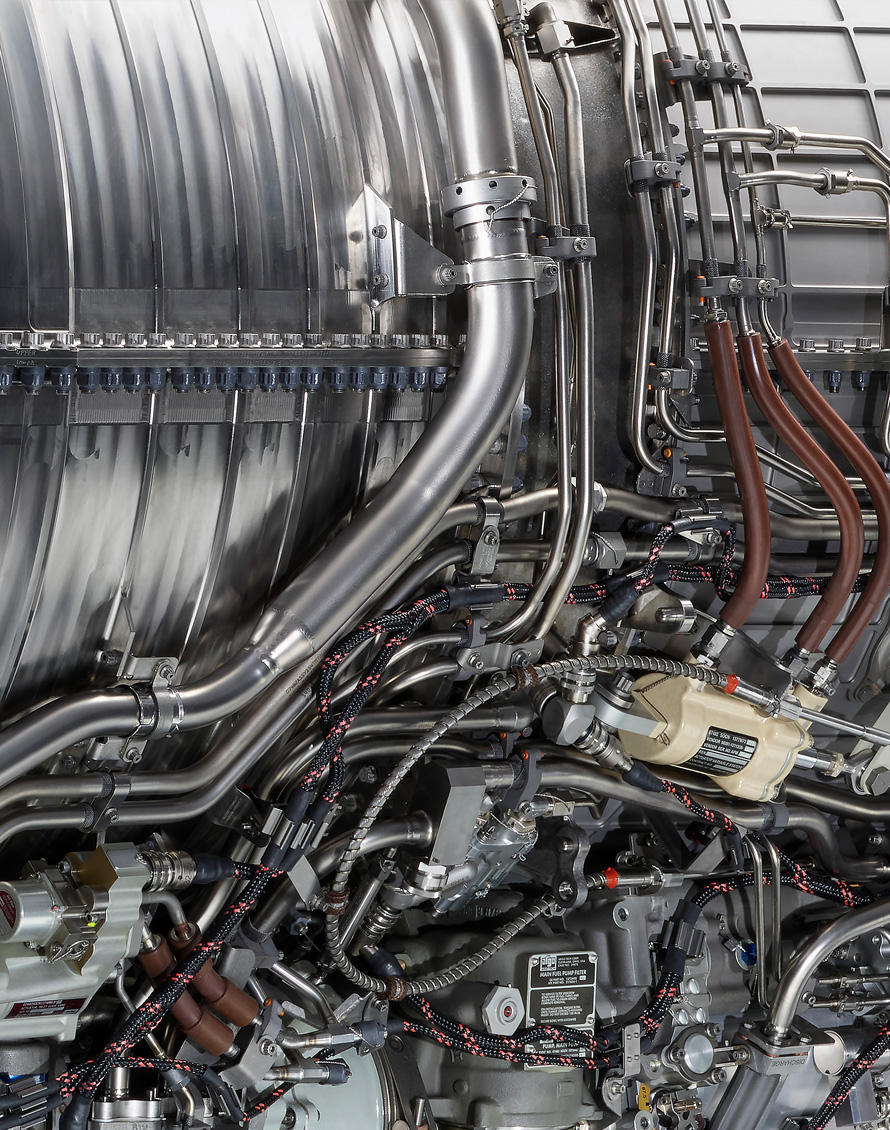

We actively support Korea's indigenous KF-21 Boramae fighter jet program (powered by the F414 engine) in collaboration with Hanwha Aerospace and Korea Aerospace Industries. We have a longstanding partnership Hanwha Aerospace, the first in-country company to manufacture the F414 engine under license. Through this cooperation, Hanwha Aerospace handles domestic assembly and parts localization of the F414 engine for the KF-21, and the F404 engine for the T-50 and FA-50 aircraft.

Avio Aero, a GE Aerospace company, is supporting Korea Aerospace Industries to develop the main gear box for the Surion, a Korean multi-role utility helicopter. This technology collaboration brings together decades of advanced component production technology to create synergies for the design, development, and production of future transmission systems.

We actively support Korea's indigenous KF-21 Boramae fighter jet program (powered by the F414 engine) in collaboration with Hanwha Aerospace and Korea Aerospace Industries. We have a longstanding partnership Hanwha Aerospace, the first in-country company to manufacture the F414 engine under license. Through this cooperation, Hanwha Aerospace handles domestic assembly and parts localization of the F414 engine for the KF-21, and the F404 engine for the T-50 and FA-50 aircraft.

Avio Aero, a GE Aerospace company, is supporting Korea Aerospace Industries to develop the main gear box for the Surion, a Korean multi-role utility helicopter. This technology collaboration brings together decades of advanced component production technology to create synergies for the design, development, and production of future transmission systems.

Commercial