Bring Them Home

Safely

Around 1M people are flying on aircraft right now powered by GE Aerospace and its joint venture partners' technology. It’s a tremendous responsibility and why safety comes first.

Laying a solid safety

foundation

FLIGHT DECK

Proprietary lean operating model

Our lean proprietary operating model is how we operate the business and helps keep our employees, customers, passengers, and everyone who counts on us safe.

Product Safety →

Worker Safety →

SQDC

Safety, Quality, Delivery, and Cost — always in that order

Safety comes first at GE Aerospace, and the company encourages employees to report safety concerns voluntarily and confidentially without fear of retaliation.

Report a safety concern →

First

Manufacturer with accepted Safety Management System

Ten years before the FAA proposed requiring Safety Management Systems for aerospace manufacturers, GE Aerospace established one.

See how our SMS is working →

View a timeline of other key safety milestones for GE Aerospace →

Maintaining Quality

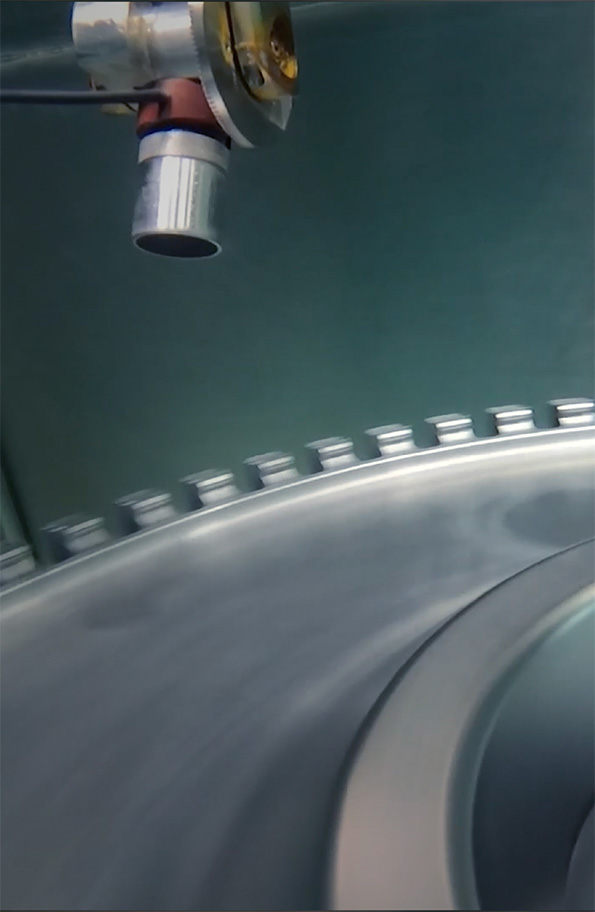

Throughout an engine’s life, we have innovative technologies to help ensure quality and safety is properly maintained. Watch short videos to learn more.

Partnership for safety

Raw material suppliers for safety-critical parts share quality data to detect defects early and continuously improve.

Real-time monitoring

We constantly review data from customers’ fleets to spot immediate issues and any potential risks.

Our work is never done

See current stories about how we are using FLIGHT DECK to keep our people and products safe.