Cooling Technology Development Project

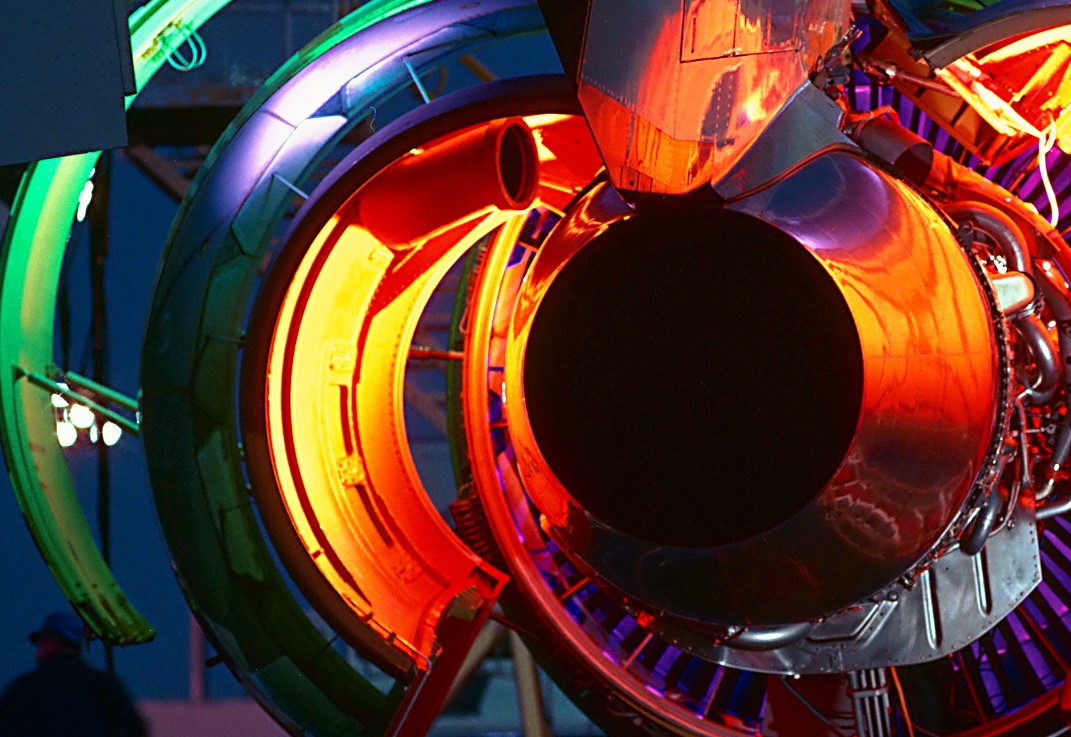

DEVELOPMENT OF COOLING TECHNOLOGY FOR HOT SECTION COMPONENTS IN ROTATING MACHINES WITH PARTICULAR REFERENCE TO HIGH-PRESSURE TURBINE BLADES AND VANES

The Project goal is to develop an innovative cooling and sealing technology as well as radial and axial clearances control system for hot section of a modern high pressure turbine. The Project result will be proprietary GECP technology and at the same time will be the first such technology ever developed in Poland.

The Project outcome will be an innovatory product that will be widely used in aircraft engines application. The project assumes to conduct R&D works during which a prototype of the high pressure turbine with the proprietary cooling technology will be developed and subsequently tested in laboratory environment as well as on a rig reflecting real operating conditions.

The Project result will significantly benefit the customers in a way of decreasing fleet operating cost by increasing effectiveness of the enigne and improving its fuel consumption. Moreover, a time between overhauls will be extended, what will impact serviceability cost and improve an overall economy of the fleet.

PROJECT IMPLEMENTATION PERIOD:

1 July 2016 - 30 June 2023

PROJECT VALUE:

Total project cost is: PLN 55,895,454.76

The value of co-financing obtained by GE Aerospace Poland

from European funds is: PLN 28,828,585.49