New Heat Resistant Composite Material

DEVELOPMENT OF A NEW HEAT RESISTANT COMPOSITE MATERIAL FOR USE IN AIRCRAFT ENGINE COMPONENTS

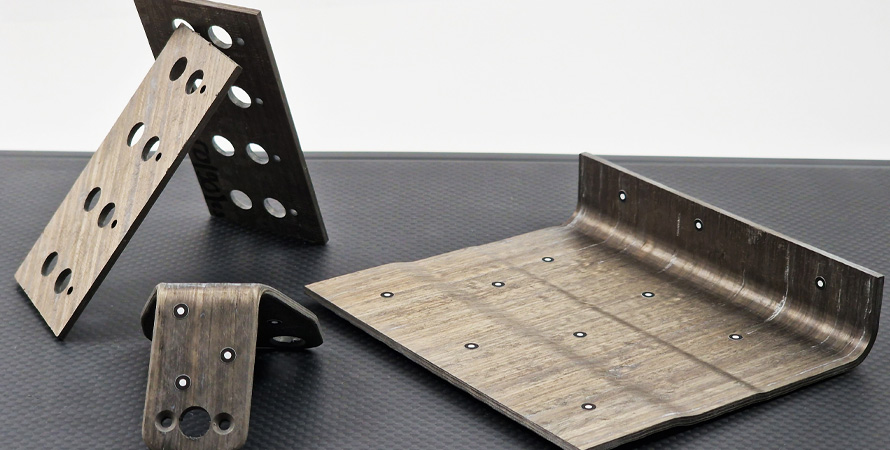

The aim of the Project is to conduct Research & Development to create an innovative product in the form of polysialate resin based composite material, together with manufacturing technology.

The developed innovation will be dedicated for aviation industry – it will find its application in the design of high-pressure compressor or high-pressure turbine components.

The Project will allow to develop a heat and creep resistant composite material capable of exceeding maximum operating temperatures for polymer matrix composites. The developed innovative material will be contemporaneously characterized by its low density and low production costs, what will enable its commercial application in aircraft engines production.

The result of the Project will be a response to the needs of aircraft manufacturers and end users (airlines), by improving the operating parameters of an aircraft engine and the entire flying unit, resulting in, among others, the reduction of fuel consumption and exhaust emission, lowering the production and maintenance costs, while maintaining continuous flight safety.

PROJECT IMPLEMENTATION PERIOD:

1 January 2020 - 30 October 2023

PROJECT VALUE:

Total project cost is: PLN 4,342,669.73

The value of co-financing obtained by GE Aerospace Poland

from European funds is: PLN 2,548,728.21