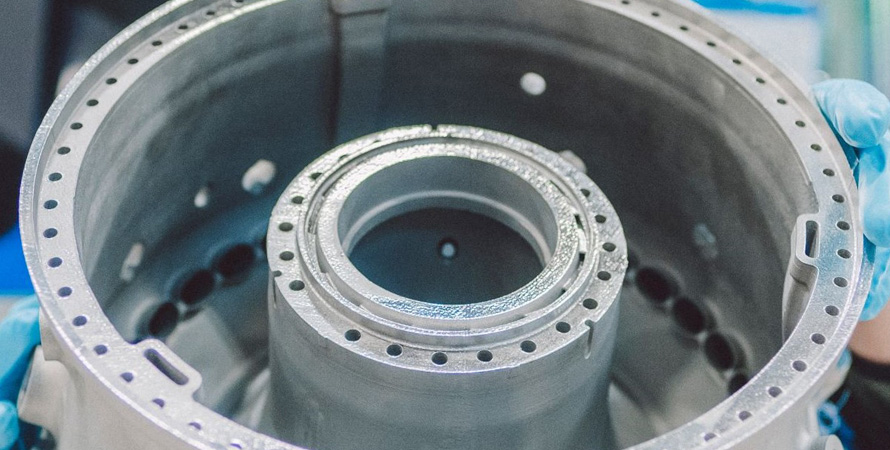

Power Turbine with Additvely Manufactured Components

DEVELOPMENT OF THE ADVANCED TURBOPROP ENGINE POWER TURBINE CONTAINING 3D PRINTED HARDWARE

The aim of the Project is to conduct Research & Development to create a product that will be innovative on a global scale – a power turbine containing components made by additive manufacturing (3D printing). The project assumes to conduct R&D works, during which a prototype of the power turbine will be developed, initially tested in laboratory environment, and subsequently tested on a rig reflecting real operation conditions of the power turbine.

The Project result – the power turbine, is a response to the market needs associated with permanently increasing demand for air transport, e.g. shortening the production lead time and providing technologically advanced concepts at a competitive price. A significant benefit to the customers, resulting from the additive manufacturing used in the Project, is the reduction of weight of the power turbine, thus the entire engine, what directly reflects in lower fuel consumption and CO2 emmision of the engine.

PROJECT IMPLEMENTATION PERIOD:

1 April 2016 - 30 April 2023

PROJECT VALUE:

Total project cost is: PLN 51,430,336.88

The value of co-financing obtained by GE Aerospace Poland

from European funds is: PLN 24,935,086.18