CFM Boosts HPT Blade Output and Repair to Meet Extended Demand for CFM56 Engines

October 29, 2025 | by GE Aerospace Staff

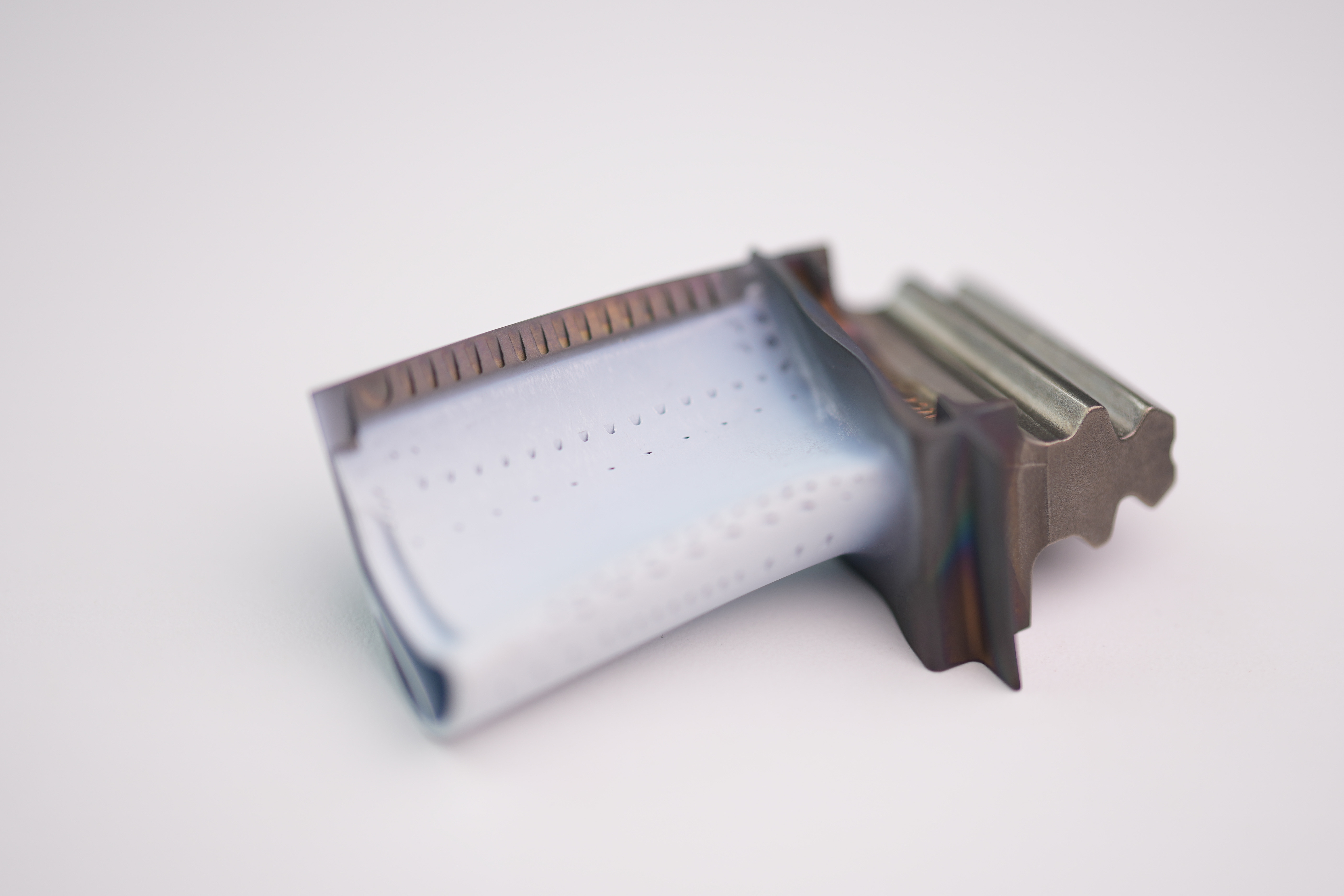

CFM International* has shipped the 1,700th set of its newest high-pressure turbine (HPT) blade, originally introduced in 2023. The enhanced blade is available for both CFM56-5B and CFM56-7B engines and improves both reliability and durability to deliver longer time on wing in severe operating environments.

“CFM’s philosophy is one of continuous investment to deliver ever-greater value to our customers,” said Gaël Méheust, president and CEO of CFM International. “We introduced this latest HPT blade nearly 30 years after CFM56-5B introduction on the A321ceo — and more than 25 years after CFM56-7B entered service on the Next-Generation 737. This new blade has been well received, and we have increased output by almost two and a half times year-over-year to meet strong demand.”

To ensure competitive cost of ownership, CFM has also continued to invest in advanced repair technologies. Since early 2023, the company has industrialized about 400 repairs for CFM56 parts. For example, the company is introducing automated laser welding for prior-generation HPT blades, increasing both part throughput and repair volume while decreasing repair turnaround time by about one-third.

“The more parts we can repair, the fewer spare parts customers need,” said Méheust. “This lowers overhaul cost and lessens demand for new material in the supply chain. The new repairs are also helping build an inventory of used serviceable material, another tool customers can use to ensure competitive cost of ownership.”

CFM’s sister company CFM Materials (CFMM) offers a variety of part-, module-, and engine-level solutions for maintenance, repair, and overhaul (MRO) shops, airlines, and lessors. With warehouses and staff across the Americas, Europe, and Asia, CFMM can quickly deploy used serviceable material (USM) to CFM56 operators around the world.

As an original equipment manufacturer, CFM leverages extensive experience in the integration and production of parts. This expertise allows for more accurate assessment of the lifespan of individual components, taking into account their interaction with other sections of the engine.

“These CFM56 services enable our customers to retain the high reliability and durability that they’ve come to expect from CFM56 engines — with customized solutions that make the most sense for their operations and fleet planning,” Méheust added. “With CFM’s ongoing innovation in this space, operators can extend time on wing and lower operating costs, while supporting the higher residual values from which owners of CFM56 engines have long benefited.”

*CFM International is a 50-50 joint company between GE Aerospace and Safran Aircraft Engines.