Engineering Excellence: Meet Three Engineers Who Represent the Future of Flight in India

July 29, 2025 | by Caroline Morris

This year, GE Aerospace’s research and engineering center in Bengaluru is celebrating its 25th anniversary, a landmark achievement for India in its aviation engineering journey. Over these 25 years, the center has evolved into one of the company’s key engineering centers, advancing technology for most of the commercial engine lines produced by GE Aerospace and CFM International* and pushing the boundaries of innovation.

Key to this continual growth is the Edison Engineering Development Program (EEDP). Each year, the EEDP admits a select number of young engineers to a two-year training program in which they gain experience in aerospace engineering, connect with mentors, and do a lot of productive networking. The goal of the program is to produce successive classes of “engineering problem solvers.”

The program is broken into two parts: the “A Course,” an advanced engineering course where Edisons are taught various aspects of aerospace engineering and are attached to a subspecialty team, and the “B Course,” in which they lead projects to address unmet business needs. This structure is different from other training programs in the emphasis it puts on taking initiative — turning these young engineers into entrepreneurs when it comes to problem solving. And it works. Since its inception, EEDP in India has produced more than 150 engineers leading exciting projects at GE Aerospace’s research and engineering center in Bengaluru.

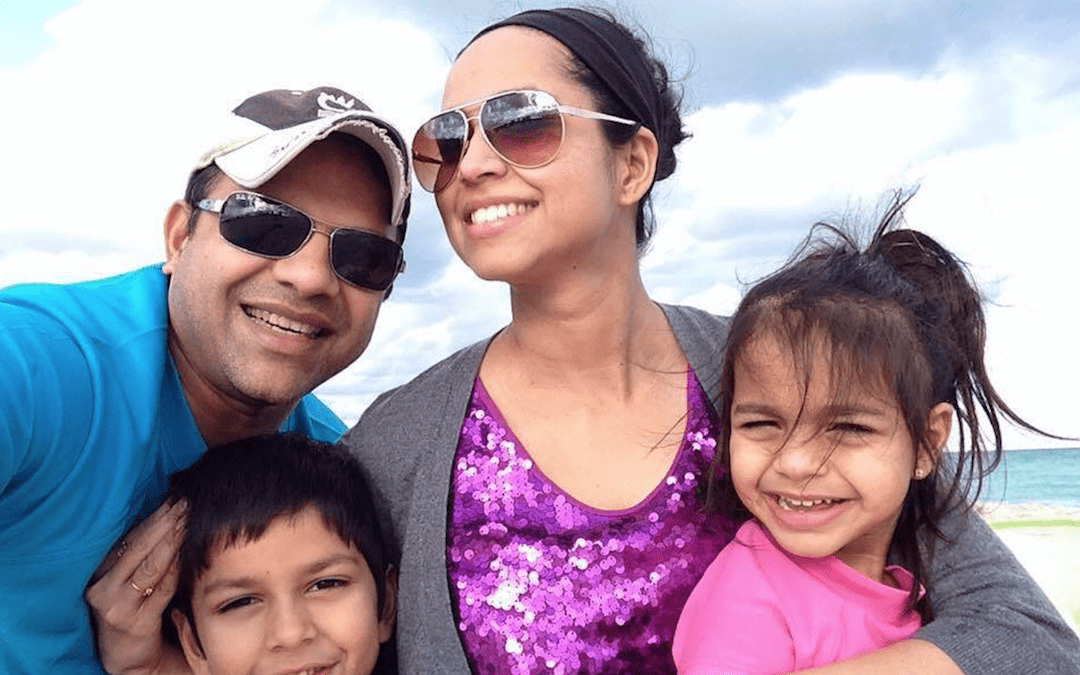

The center’s 25th anniversary is particularly special for three engineers who are currently finishing their first year in the program, because they all happen to be 25 years old as well. These three will be growing as people and as professionals alongside the center for the rest of their careers, sharing anniversaries for years to come.

We sat down with these three EEDP engineers and let the tape roll as they reflected on the end of their first rotation and what their future may hold.

Neha Bhosale: Material (Science) Girl

A key source of finding great candidates for the program is through on-campus recruitment events, which is how Neha Bhosale discovered EEDP. Her first rotation was spent in the Materials Engineering team, which aligned perfectly with her fascination with material science. Becoming an EEDP engineer opened her eyes to the critical role that material science — the study of how materials withstand extreme temperatures and mechanical stresses — plays in aviation engineering. “Aviation engineering is such a dynamic field — it’s where science, technology, and creativity all come together to solve some of the most complex challenges,” says Bhosale. “Joining the Edison Engineering Development Program felt like the perfect opportunity to combine my materials expertise with aerospace technology.”

During her first rotation in engineering, Bhosale focused on materials behavior; she analyzed data and created material property curves to show how materials function and how much stress they can handle. She was better able to take on this role thanks to her A Course classes. “Since my background is in materials, I didn’t know much about aerospace or mechanical engineering at first, but these sessions helped me to understand the basics and connect my work to the bigger picture here,” she says.

One of the highlights of Bhosale’s first year in EEDP was the Aerospace Foundation Seminar, a five-day event in Cincinnati where EEDP engineers from around the world are immersed in GE Aerospace’s core values, including in-depth tutorials on the company’s products and the principles of safety, quality, delivery, and cost (SQDC), which help the company deliver value to its customers. “It was a milestone experience that not only helped me grow professionally but also gave me a deeper appreciation for GE Aerospace’s values and culture,” she says.

As part of her second rotation with the Materials and Coatings Research team, Bhosale is excited to work on the CFM RISE development program, which is advancing a suite of technologies like Open Fan for 20% better fuel efficiency than commercial aircraft engines today. In its pursuit of more efficient flight, the team is studying ways to incorporate more composite materials, which are lighter, in place of metal components, which tend to be heavier. Bhosale’s expertise in material science has turned out to be a boon in meeting this need.

“The EEDP program takes forward what Thomas Edison taught us, which is asking and identifying what the world needs and coming up with a solution,” says Satya Reddy, EEDP program manager. “So we take young engineers from college, challenge them, help map their special skills to what the world needs, and deliver it together.”

Sachin Sundarrajan: Feeling the Steel

As a child, Sachin Sundarrajan would assemble robotic toys to try and figure out how machines come together and function. This was the root of his interest in complex mechanical systems and design, and he ultimately got his master’s degree in machine design in 2024. After visiting an EEDP on-campus recruitment event, it was a natural next step to explore aerospace engineering. “The aerospace industry is kind of the pinnacle of mechanical design. Every aspect of engineering comes together to make something which is highly reliable and safe to operate,” says Sundarrajan. As an engineer on the Mechanical Analysis Team, he’s been using finite element analysis to evaluate the stresses on the rotating components in the engine under operating conditions.

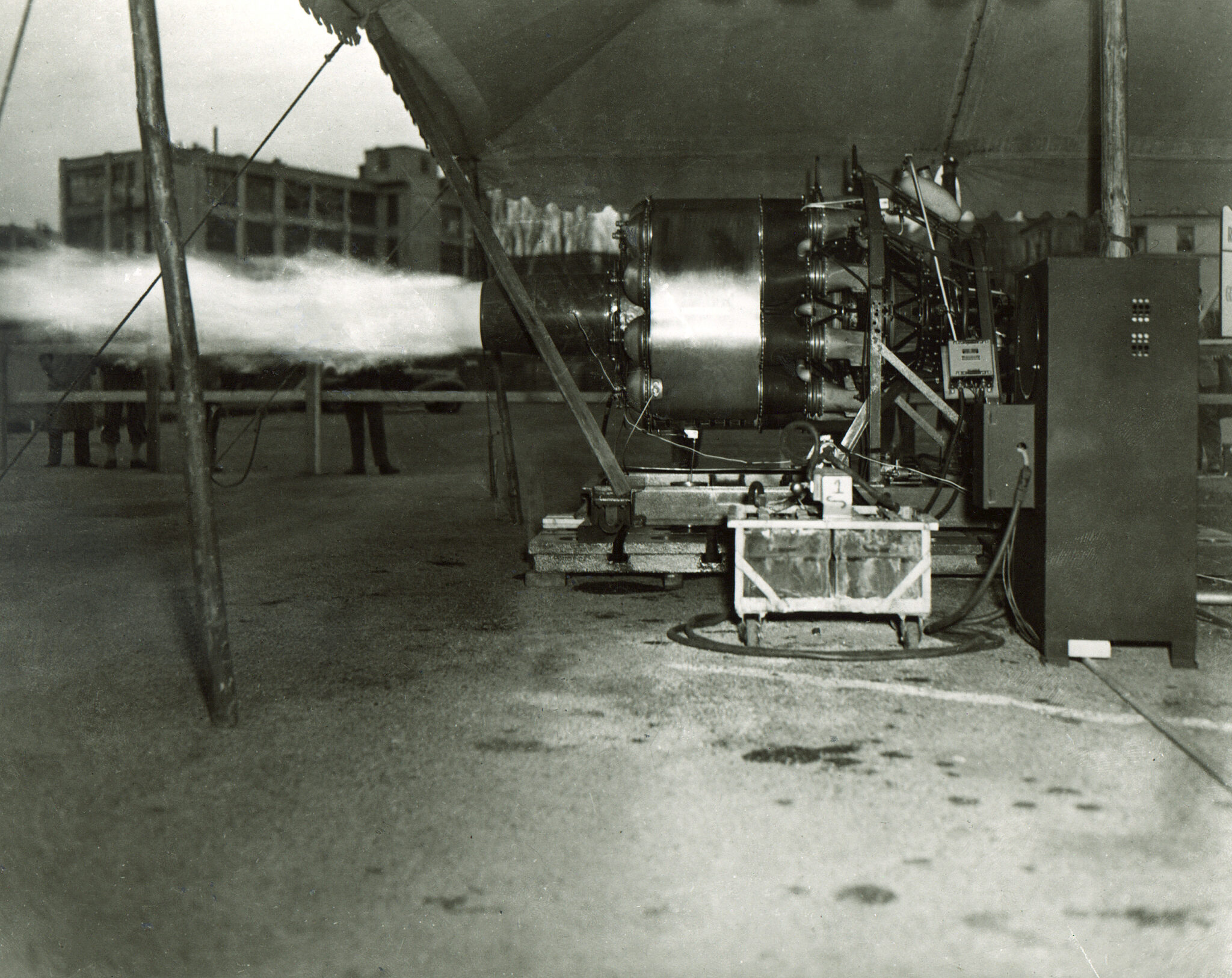

In addition to their courses and work during their first year, the engineers have visited GE Aerospace facilities, such as the jet engine test operations site in Peebles, Ohio, and the narrowbody engine production line in Lafayette, Indiana, where they’ve gotten a firsthand education in the company’s principles, processes, and legacy of innovation. In addition to getting up close with some of the engines and systems they’ve worked on from afar, the trio also have seen FLIGHT DECK, GE Aerospace’s proprietary lean operating model, in action — whether learning about new processes that have improved efficiency inside a production facility or advances in testing that continue to improve the safety and reliability of the company’s engines. “We got the chance to see and — I like to say this — to feel the steel. That is, to feel the actual component that we design and do analysis on here in the Bengaluru research and engineering center,” says Sundarrajan.

For his B Course project, Sundarrajan intends to study the use of artificial intelligence to solve problems in core engineering. And if he runs into obstacles, he has the expert resources to overcome them, thanks to the program’s emphasis on networking and mentorship. “The EEDP program facilitates this because we are taught by a different instructor for each subject module of the A Course every week,” he says. “These instructors are veteran engineers in their respective fields. And thus we, as engineers, have 28 different domain expert connections.”

They also have a wide-reaching network as a result of the relationships they’ve built with other engineers around the world, enhancing the entire cohort’s understanding of global aerospace challenges and their ability to find solutions.

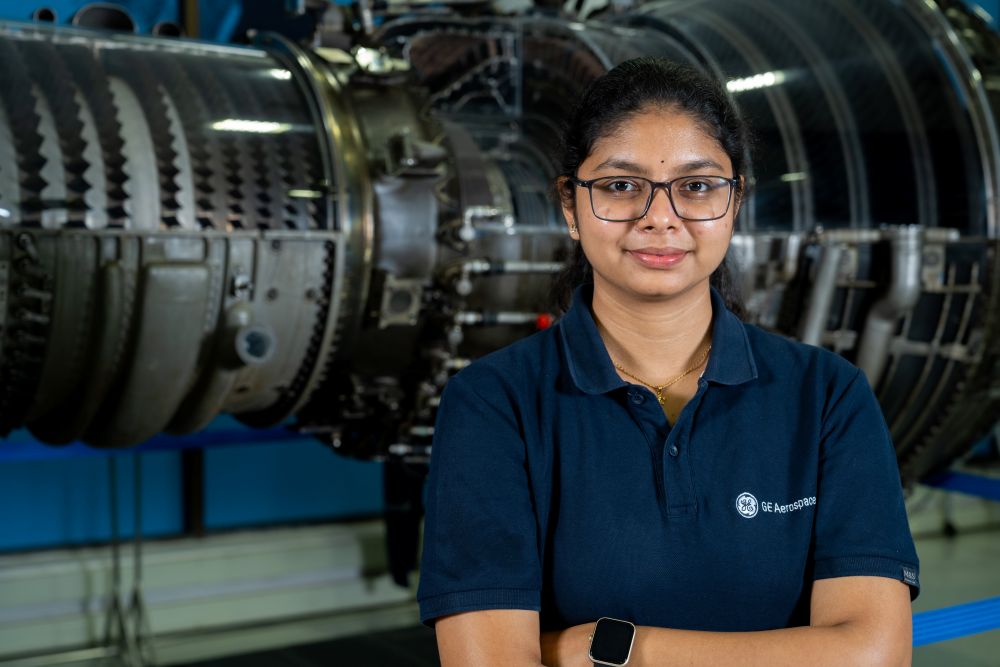

Geethika Kilari: All About Adding Value

Geethika Kilari’s journey with GE Aerospace began during her internship while pursuing a master’s degree in power electronics and power systems. During her internship, she had the opportunity to work on the RISE program, which made a lasting impression. “I came to know how an electrical engineer plays a role in the aerospace domain, and all the opportunities that I can have here,” Kilari says. Inspired by this experience, she applied to the EEDP and is now part of the Electrical Power Team.

As an EEDP engineer, Kilari is contributing to the development of a hybrid-electric converter for the RISE program. Her role involves conducting pre-test predictions to assess how the converter will perform during practical tests. Additionally, she performs simulations to identify and address any anomalies that may arise during testing. “It’s pretty much reverse engineering as well as forward engineering at the same time,” she explains.

EEDP is designed to create well-rounded engineers, and Kilari finds the program’s A Course particularly impactful. The A Course provides foundational knowledge, while the upcoming B Course will focus on applying that knowledge to lead and implement solutions. “That’s my definition of a well-rounded engineer,” she says. “We need to find an unmet need and add value to something that we are already working on.”

Kilari is excited to help advance the future of flight and sees great potential in the aerospace field, particularly in India, where the demand for air travel has increased dramatically in the past two decades. “So much value lies in this field, and we have a lot of capable engineers here,” she says. “By focusing on more sustainable technology solutions for our aircrafts, we are working on moving innovation forward here at GE Aerospace in India.”

*CFM International is a 50-50 joint company between GE Aerospace and Safran Aircraft Engines.