Passion in 3D: Aviation Hobbyist Prints CFM RISE Open Fan Model From Scratch

July 17, 2022 | by Nick Hurm

Alex Hills developed a passion for 3D printing like most hobbyist interested in the process. He bought a 3-D printer and began “tinkering around” with some simple print builds.

Around 2012, Hills printed his first generic jet engine design off plans that he discovered online. “It was a real simple model that spun with some bearings,” Hills recalls. “I thought it was cool and printed another one that I put on my desk.”

As he progressed, so did the degree of difficulty of his projects. Hills, a sub-section manager for test enabling hardware at GE, spent a half year building two, six-foot Saturn V rocket replicas for the National Museum of the United States Air Force in Dayton, Ohio.

“I’ve been a volunteer there for 14 years and have been coming up with STEM projects for education and family events,” he said. “That project gave me a lot of experience and technique.”

https://youtu.be/CDA1mQjC8LE

Hills was interested in printing something more GE specific since his primary work for the company is building engine test hardware such as cowling doors and fan ducts for various programs, including CFM International's LEAP and GE9X engines.

“I really couldn’t find 3D-printed engine plans online that were GE or CFM specific, so I wanted to build something that represents what I’ve worked on,” he said.

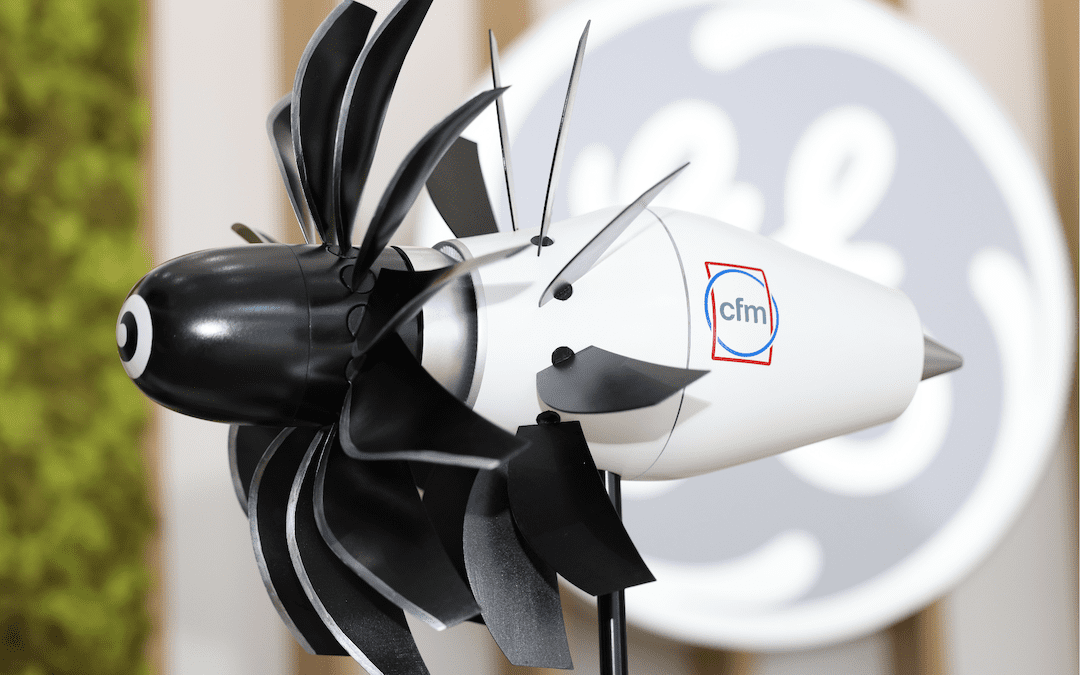

In June of 2021, Hills zeroed in on his next project after watching a video of the newly-announced CFM RISE Program, which includes advanced new engine architectures an open fan engine. The concept does not look like conventional jet engine designs and features an advanced 14-foot diameter fan in the front, with a row of non-rotating variable-pitch stators behind it.

“The CFM video had a 360 degree, 3D rendering of the engine. I thought it would be great to build an actual model of the open fan, so I began reverse engineering the design in software for 3D printing.”

Hills never printed a project without plans prior to this endeavor, let alone an architecture that was so challenging. With the help of the video, he was able to piece together a design from scratch. “The video gives you straight-forward images of the concept. I roughly scaled things on how big the engine would be based on what information was out there. I was able to develop a model from that,” he said.

Hills worked on the fan first. “It’s a real interesting fan. On older ducted fans, the blades stay at a fixed pitch. For this engine, since it’s unducted, to get reverse thrust capabilities, you have to pitch these blades and you can see they rotate on the hub. It was a challenge.”

After many hours of eyeing dimensions and generating a design, Hills finished his first open fan model last fall. Instead of displaying it on his desk, Hills donated it to GE's Cincinnati-based Community Service Fund and the model was auctioned off for $900.

Word spread quickly within GE circles about the model and eventually the news made its way to Chris Lorence, a chief engineer and general manager for GE. Lorence was preparing for an industry sustainability conference in Europe and needed something to catch people's attention. There were videos to illustrate the concept but once he discovered Hills' open fan model, Lorence knew it would be a great asset for the conference.

In approximately 10 days, Hills built another model and met Lorence just in time to hand it off for his trip. "The paint was still drying!" said Hills.

"It turned out to be a great way to let people see what we are talking about with these technologies," said Lorence. "Pictures and videos are just not the same as the tactile element of being able to get up close to an engine model, particularly something as innovative as the RISE open fan, which is so different than what we've done historically in the industry."

Hills has not stopped building these models and continues to refine new versions. His latest build includes removable magnetic rotor blades, a gearing mechanism for the stators and fan blades, a more detailed core with LED lights, and even jet engine sounds from audio he got of a GE90 running up and shutting down. Eventually, Hills plans to design a pylon attachment that would hook on to a wing model.

"One of the great things about Alex and the engineering team here at GE is they have such a passion for our product," said Lorence. "It goes beyond the design work and the day-to-day challenges. People here get very excited about inventing the future. Alex is a great example of how that enthusiasm can reach beyond the workplace."

*LEAP and RISE are products of CFM International is a 50/50 joint business between GE and Safran Aircraft Engines.

Around 2012, Hills printed his first generic jet engine design off plans that he discovered online. “It was a real simple model that spun with some bearings,” Hills recalls. “I thought it was cool and printed another one that I put on my desk.”

As he progressed, so did the degree of difficulty of his projects. Hills, a sub-section manager for test enabling hardware at GE, spent a half year building two, six-foot Saturn V rocket replicas for the National Museum of the United States Air Force in Dayton, Ohio.

“I’ve been a volunteer there for 14 years and have been coming up with STEM projects for education and family events,” he said. “That project gave me a lot of experience and technique.”

https://youtu.be/CDA1mQjC8LE

Hills was interested in printing something more GE specific since his primary work for the company is building engine test hardware such as cowling doors and fan ducts for various programs, including CFM International's LEAP and GE9X engines.

“I really couldn’t find 3D-printed engine plans online that were GE or CFM specific, so I wanted to build something that represents what I’ve worked on,” he said.

In June of 2021, Hills zeroed in on his next project after watching a video of the newly-announced CFM RISE Program, which includes advanced new engine architectures an open fan engine. The concept does not look like conventional jet engine designs and features an advanced 14-foot diameter fan in the front, with a row of non-rotating variable-pitch stators behind it.

“The CFM video had a 360 degree, 3D rendering of the engine. I thought it would be great to build an actual model of the open fan, so I began reverse engineering the design in software for 3D printing.”

Hills never printed a project without plans prior to this endeavor, let alone an architecture that was so challenging. With the help of the video, he was able to piece together a design from scratch. “The video gives you straight-forward images of the concept. I roughly scaled things on how big the engine would be based on what information was out there. I was able to develop a model from that,” he said.

Hills worked on the fan first. “It’s a real interesting fan. On older ducted fans, the blades stay at a fixed pitch. For this engine, since it’s unducted, to get reverse thrust capabilities, you have to pitch these blades and you can see they rotate on the hub. It was a challenge.”

After many hours of eyeing dimensions and generating a design, Hills finished his first open fan model last fall. Instead of displaying it on his desk, Hills donated it to GE's Cincinnati-based Community Service Fund and the model was auctioned off for $900.

Word spread quickly within GE circles about the model and eventually the news made its way to Chris Lorence, a chief engineer and general manager for GE. Lorence was preparing for an industry sustainability conference in Europe and needed something to catch people's attention. There were videos to illustrate the concept but once he discovered Hills' open fan model, Lorence knew it would be a great asset for the conference.

In approximately 10 days, Hills built another model and met Lorence just in time to hand it off for his trip. "The paint was still drying!" said Hills.

"It turned out to be a great way to let people see what we are talking about with these technologies," said Lorence. "Pictures and videos are just not the same as the tactile element of being able to get up close to an engine model, particularly something as innovative as the RISE open fan, which is so different than what we've done historically in the industry."

Hills has not stopped building these models and continues to refine new versions. His latest build includes removable magnetic rotor blades, a gearing mechanism for the stators and fan blades, a more detailed core with LED lights, and even jet engine sounds from audio he got of a GE90 running up and shutting down. Eventually, Hills plans to design a pylon attachment that would hook on to a wing model.

"One of the great things about Alex and the engineering team here at GE is they have such a passion for our product," said Lorence. "It goes beyond the design work and the day-to-day challenges. People here get very excited about inventing the future. Alex is a great example of how that enthusiasm can reach beyond the workplace."

*LEAP and RISE are products of CFM International is a 50/50 joint business between GE and Safran Aircraft Engines.