GE’s Military Engine Portfolio Charting Future of Military Aviation Entering Farnborough

July 17, 2022 | by GE Aviation News Staff

Progress testing next-generation engines and continued global competitiveness with in-production engines highlight GE’s strong military portfolio entering the 2022 Farnborough International Airshow.

GE is in the midst of major test campaigns for transformational combat and rotorcraft engines. GE’s XA100* adaptive cycle engine for the F-35 has demonstrated performance consistent with the U.S. Air Force’s goals for the Adaptive Engine Transition Program (AETP). This engine is expected to complete testing at a U.S. Air Force facility later this summer.

Meanwhile, GE’s T901 turboshaft engine completed its First Engine to Test (FETT) campaign in late June as part of the U.S. Army’s Improved Turbine Engine Program (ITEP). The T901 is demonstrating performance in line with the U.S. Army’s goals and will re-engine the Army’s UH-60 and AH-64 fleets, as well as power the Army’s Future Attack Reconnaissance Aircraft (FARA).

Additionally, GE’s fielded products continue to perform for military customers around the world. The T700/CT7 turboshaft engine family offers proven, reliable power for applications around the world, while GE’s T408 engine powered the Sikorsky CH-53K to Initial Operational Capability (IOC) with the U.S. Marine Corps in April. Deliveries of GE’s F110 engine are ongoing for the U.S. Air Force’s F-15EX platform as well as international users. The F414-powered KF-21 Boramae’s first flight is anticipated soon, and the F404 engine is readying for a historic production ramp.

TESTING

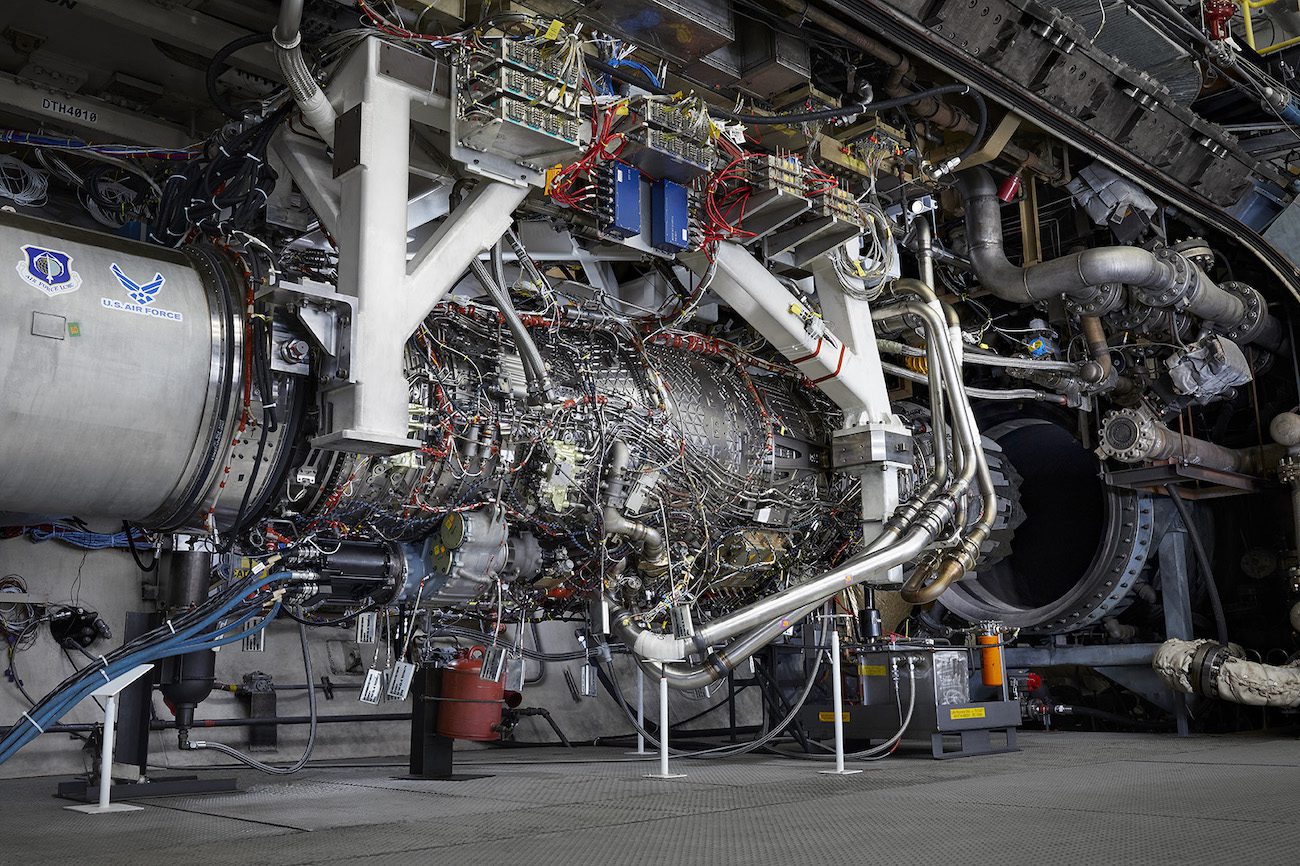

GE’s second XA100 adaptive cycle engine is undergoing testing at the U.S. Air Force’s Arnold Engineering Development Complex (AEDC) in Tullahoma, Tenn. Designed to fit the F-35A and F-35C with no structural modifications to either airframe, GE’s XA100 has demonstrated transformational performance through testing, which began in December 2020. This includes 25% better fuel efficiency, 10% more thrust, and significantly more power and thermal management capacity than today’s engines. Those improvements would enable 30% more range, 20–40% faster acceleration, and double the mission systems capability for the F-35.

The XA100 incorporates the latest in GE’s technology portfolio, including Ceramic Matrix Composites (CMCs) and 3D-printed (additive) parts to help unlock game-changing performance.

https://www.youtube.com/watch?v=5PLjjCS4V-A

“We’re proud of what we’ve accomplished to date with the U.S. Air Force on the XA100,” said David Tweedie, GE Edison Works’ vice president and general manager, Advanced Products. “Our focus is on a strong finish to the AEDC test campaign, which will demonstrate both a return on the significant taxpayer and Air Force investment in this program, as well as GE’s readiness to move into a low-risk Engineering and Manufacturing Development (EMD) program.”

GE’s T901 turboshaft engine recently concluded its FETT campaign, which began on March 25, 2022. Testing consisted of more than 100 hours of run time in a Lynn, Mass., test cell.

“The first T901 engine test campaign was successful and demonstrated performance consistent with the Army’s goals,” said Tom Champion, GE’s T901 program director. “That performance makes this an extremely important program for the future of Army Aviation. We’re fully focused on the coming months of testing and delivering this capability to the Warfighter.”

https://www.youtube.com/watch?v=hvuezmsuVxw&t=1s

Performance goals for this engine include 50% more power, 25% better specific fuel consumption (SFC), and improved durability and life cycle costs compared to the T700 engine. The T901 won the Improved Turbine Engine Program (ITEP) competition to re-engine the U.S. Army’s UH-60 Black Hawk and AH-64 Apache fleets in 2019. The T901 was also selected to power both Future Attack Reconnaissance Aircraft (FARA) competitive prototypes and will power the Army’s selected FARA production aircraft. GE continues working closely with the Army to deliver flight test engines later this year to support the FARA competitive prototype fly-off.

In February 2022, GE and the Army Research Laboratory began a research and development program called the Applied Research Collaborative Systematic Turboshaft Electrification Project (ARC-STEP). Included in this project is the research, development, testing, and evaluation of a megawatt (MW) class electrified powerplant that further develops technologies applicable to Army Future Vertical Lift (FVL). Development is ongoing at GE’s research campus in Niskayuna, N.Y., with a CT7 turboshaft engine.

IN-PRODUCTION PRODUCTS

With more than 25,000 engines delivered to date, the T700/CT7 turboshaft engine family continues to represent a compelling option for proven, reliable power for dozens of applications around the world.

GE powers the Leonardo AW149 and AW189, which are in service today with the CT7-2E1 engine. The CT7-2E1 has proven itself with reliable operations in harsh and maritime environments while offering lower engine weight, lower fuel consumption, and maintenance cost advantages compared to competing engines for the AW149. Meanwhile, the T700-GE-701D for the Sikorsky S-70M Black Hawk offers decades of front-line combat experience and 100% engine commonality with the Boeing AH-64E Apache fleet currently being delivered to the U.K. Armed Forces. Thus, both the CT7-2E1 and T700-701D offer a high level of commonality with an existing U.K. platform. Local sustainment for the AH-64E engine fleet will be provided by H+S Aviation in Portsmouth, U.K.

GE’s powerhouse T408 turboshaft engine continues providing transformational heavy-lift capabilities for the Sikorsky CH-53K King Stallion helicopter, which achieved Initial Operating Capability (IOC) with the U.S. Marine Corps in April. To date, the T408 has accumulated more than 20,000 ground and flight hours. The CH-53K represents a compelling offering to U.S. allies and partners as well, with each T408 engine offering 57% more power, 18% better specific fuel consumption, and 63% fewer parts compared to the T64 engine.

GE's T408 engine.

GE's T408 engine.

The F404/F414 family of engines remains a compelling, versatile and cost-effective choice for fighter and trainer platforms around the world. The F404 will see a historic production ramp to support the U.S. Air Force’s acquisition of the Boeing T-7A Red Hawk trainer jet (F404-GE-103 variant), as well as a contract for 99 F404-GE-IN20 engines for India’s HAL Tejas Mk 1/1A fighter.

Program leaders recently spent a week in Lynn, Mass., the home of F404 final assembly, for a lean event to prepare the line for the ramp. “We’re feeling energized following the great week we had in Lynn this June using lean tools to prepare for the F404 production ramp,” said Shawn Warren, GE’s vice president and general manager, Combat and Trainer Engines. “The F404 production line hasn’t required this level of production in years, so we’re focused on meeting the demand and building on the outstanding legacy of the F404 engine.”

Boeing's T-7A Red Hawk, powered by a single GE F404-GE-103 engine. Credit: Boeing

Boeing's T-7A Red Hawk, powered by a single GE F404-GE-103 engine. Credit: Boeing

Meanwhile, the F414 engine is expecting milestone flights soon. South Korea’s KF-21 Boramae is expected to achieve its first flight soon, powered by two F414-GE-400K engines. GE received a contract in 2016 to provide engines to Korea Aerospace Industries (KAI) for the KF-21 (then KF-X) program. NASA’s X-59 Quiet SuperSonic Transport (QueSST) is also progressing toward first flight, powered by a single F414-GE-100 engine. The aircraft is designed to reduce a supersonic boom to a “thump” while also gathering data to deliver to regulators in an effort to open commercial supersonic flight over land. Additionally, the F414 powers every Boeing F/A-18E/F Super Hornet in service today and would provide combat-proven, reliable performance as part of the Block III Super Hornet bid for India’s multi-role carrier-borne fighter (MRCBF) program. The F414 also powers the Boeing E/A-18 Growler along with the SAAB Gripen E/F, which saw its first deliveries to the Brazilian Air Force in 2021.

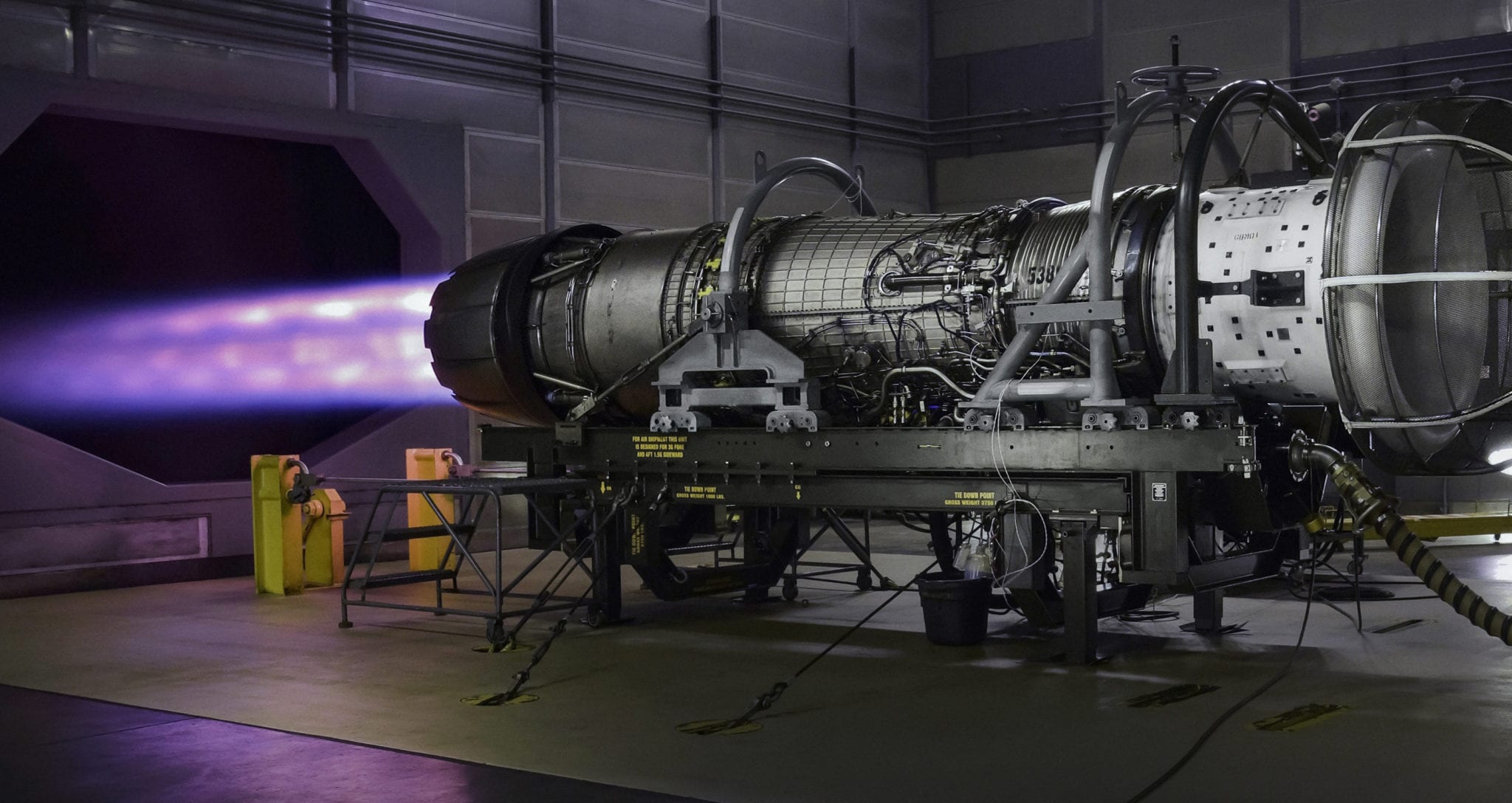

GE’s F110 engine was selected in October 2021 for the U.S. Air Force’s F-15EX Eagle II program. It remains the only propulsion solution certified, integrated, and in production for the Advanced, fly-by-wire F-15 platform. The F110 continues to prove its capability and reliability worldwide, powering F-15, F-16 and F-2 aircraft in service with 14 air forces. Approximately 70% of the U.S. Air Force’s F-16 Fighting Falcon fleet is powered by the F110 engine. Additionally, the F110 was selected to power new F-16 Block 70 aircraft during several recent international acquisitions.

GE's F110 at full afterburner during a ground test. Credit: U.S. Air Force

GE's F110 at full afterburner during a ground test. Credit: U.S. Air Force

*The XA100 is a product of GE Edison Works, a business unit dedicated to the research, development, and production of advanced military solutions. This business unit has full responsibility for strategy, innovation, and execution of advanced programs.