Top Five Milestones in GE's Hybrid Electric Technology Development

July 19, 2022 | by Chelsey Levingston

After years of maturing components of high-power hybrid electric systems, GE announced its latest testing milestone at this week’s Farnborough International Airshow.

GE has completed the world’s first test of a megawatt (MW)-class and multi-kilovolt (kV) hybrid electric propulsion system in altitude conditions that simulate single-aisle commercial flight. Altitude testing took place at NASA’s Electric Aircraft Testbed (NEAT) facility in Sandusky, Ohio.

This major milestone is significant for the future of flight, helping to validate the technical feasibility of the hybrid electric system architecture GE is developing. Moving forward, testing will continue under NASA’s Electrified Powertrain Flight Demonstration (EPFD) project with plans to conduct a flight demonstration of a hybrid electric propulsion system in the middle of the decade. As part of EPFD, Boeing is partnering with GE to support the flight tests.

“We’re making aviation history by developing the technology to help make hybrid electric flight possible for everyday commercial air travel,” said Mohamed Ali, vice president and general manager of engineering for GE Aerospace.

Here are five key milestones in GE’s development of hybrid electric propulsion systems that built up to the latest altitude integration test revealed at Farnborough:

In 2013, GE opened the EPISCenter (Electrical Power Integrated Systems Center) in Dayton, Ohio, a dedicated facility for developing and testing electric power components and systems for aircraft.

GE’s Systems business has designed and manufactured power conversion, distribution and control systems for commercial aircraft for over 30 years. GE Aviation Systems continues to advance these products with technologies such as GE-developed silicon carbide transistors to increase efficiency, power density, thermal performance and reliability while protecting aircraft safety. These technologies are integral to the development of GE’s hybrid electric powertrain demonstrator with NASA, with development work taking place at the EPISCenter in Dayton, Ohio, and the Electrical Power Integration Centre in Cheltenham, UK. EPISCenter has the capacity to test hybrid or fully electric powertrains with up to 15 megawatts of available power.

In 2015, GE teams successfully extracted one MW of electrical power with an F110 engine in a ground-level test cell, followed by a 2016 demonstration of MW power extraction at flight-representative altitude conditions.

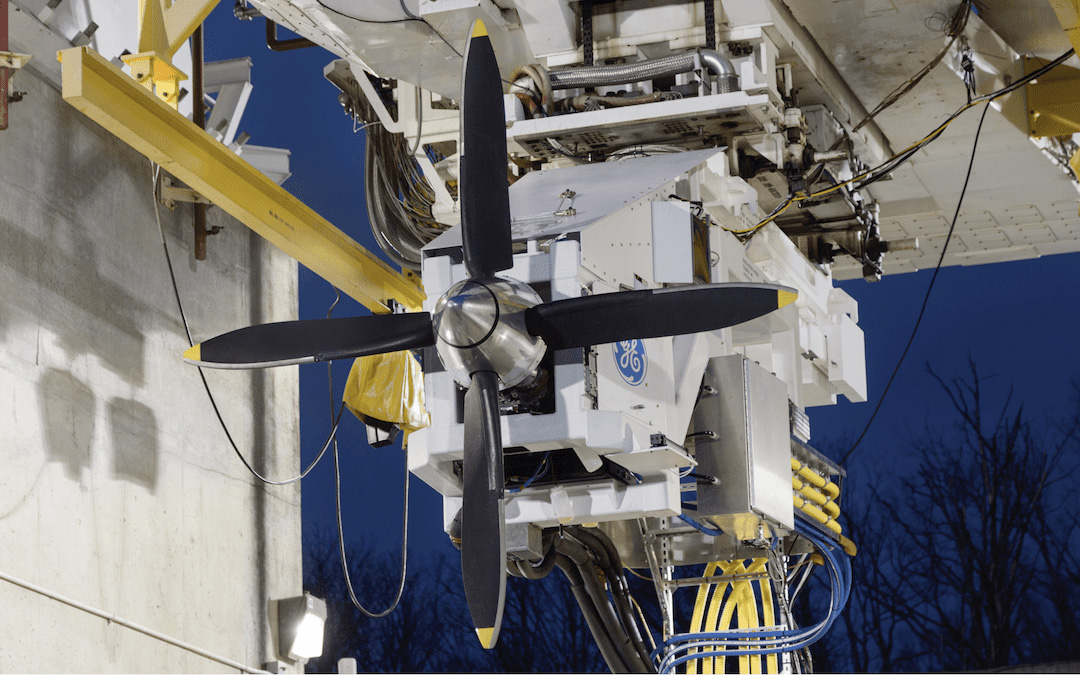

Shortly after a dedicated engineering team was formed at GE to focus on hybrid electric propulsion development, they demonstrated in 2016 an electric machine consisting of a MW-class motor/generator, electrically powering an 11-foot diameter propeller on a test stand.

A component demonstration began in 2019 of a MW-class motor/generator at altitude conditions up to 36,000 feet at NASA’s NEAT facility in Sandusky, Ohio. GE believes this was the world’s first power dense, MW- and kV- class electric machine tested at flight-representative conditions.

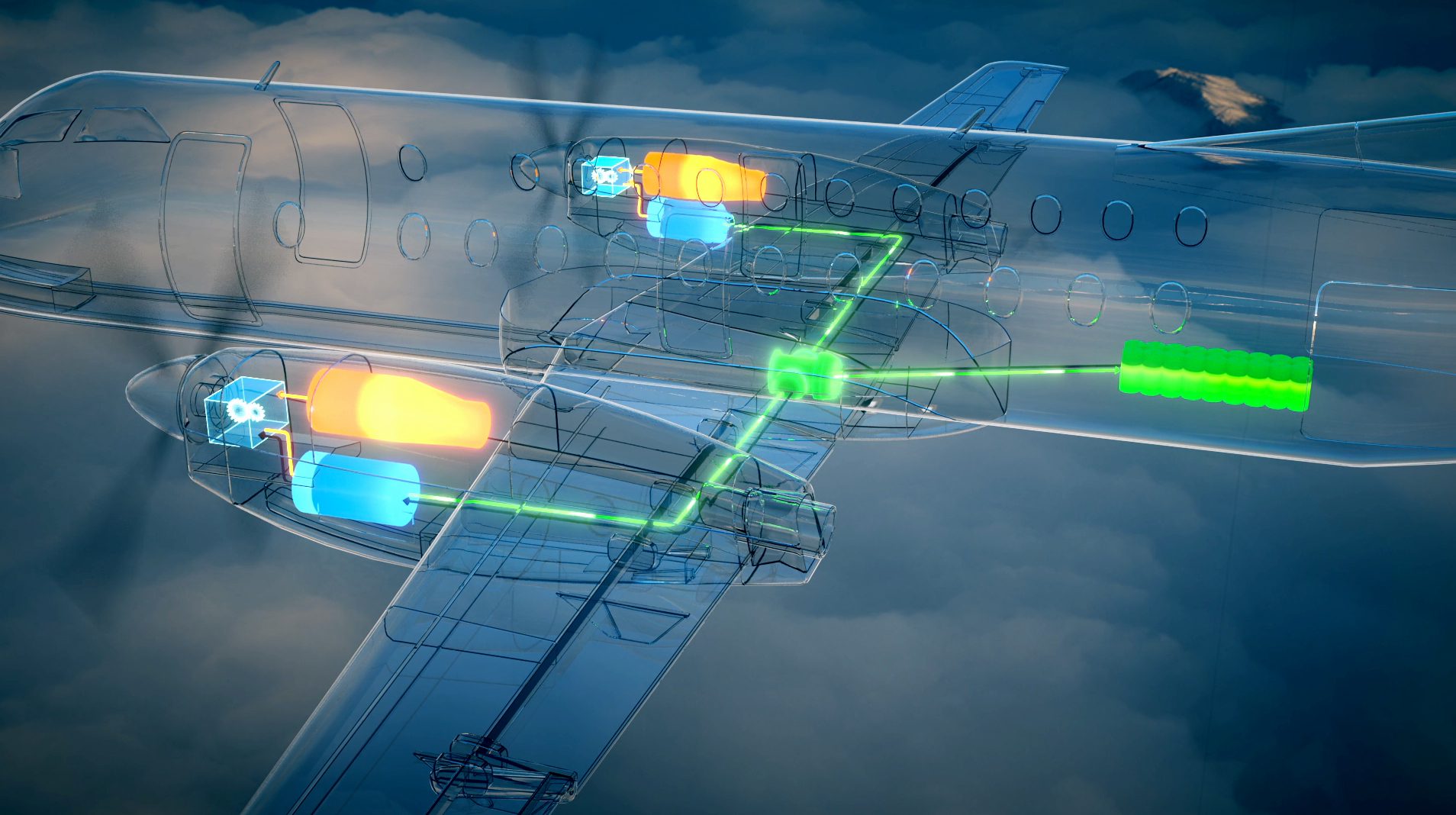

NASA announced in September 2021 a new research partnership with GE to launch a hybrid electric technology demonstrator program. After years of maturing individual components of a hybrid electric system—motors, generators and power converters—GE will systematically mature an integrated hybrid electric powertrain to demonstrate flight readiness for single-aisle aircraft. Plans are to conduct ground and flight tests of the hybrid electric propulsion system by the mid-2020s using a modified Saab 340B testbed and GE’s CT7 turboprop engines.

The most recently completed altitude integration test announced at Farnborough tested components independently and as an integrated system. Additionally, multiple operational modes were evaluated, including power transfer from side to side, power assist to a simulated engine, and aircraft power generation. The implementation of energy storage was also simulated.

The components used in the most recent altitude integration test have now been tested for thousands of hours since 2016 across sub-component, component, sub-system and system-level testing.

https://www.youtube.com/watch?v=jBu9g6kab9M

GE has completed the world’s first test of a megawatt (MW)-class and multi-kilovolt (kV) hybrid electric propulsion system in altitude conditions that simulate single-aisle commercial flight. Altitude testing took place at NASA’s Electric Aircraft Testbed (NEAT) facility in Sandusky, Ohio.

This major milestone is significant for the future of flight, helping to validate the technical feasibility of the hybrid electric system architecture GE is developing. Moving forward, testing will continue under NASA’s Electrified Powertrain Flight Demonstration (EPFD) project with plans to conduct a flight demonstration of a hybrid electric propulsion system in the middle of the decade. As part of EPFD, Boeing is partnering with GE to support the flight tests.

“We’re making aviation history by developing the technology to help make hybrid electric flight possible for everyday commercial air travel,” said Mohamed Ali, vice president and general manager of engineering for GE Aerospace.

Here are five key milestones in GE’s development of hybrid electric propulsion systems that built up to the latest altitude integration test revealed at Farnborough:

- EPISCenter opening

In 2013, GE opened the EPISCenter (Electrical Power Integrated Systems Center) in Dayton, Ohio, a dedicated facility for developing and testing electric power components and systems for aircraft.

GE’s Systems business has designed and manufactured power conversion, distribution and control systems for commercial aircraft for over 30 years. GE Aviation Systems continues to advance these products with technologies such as GE-developed silicon carbide transistors to increase efficiency, power density, thermal performance and reliability while protecting aircraft safety. These technologies are integral to the development of GE’s hybrid electric powertrain demonstrator with NASA, with development work taking place at the EPISCenter in Dayton, Ohio, and the Electrical Power Integration Centre in Cheltenham, UK. EPISCenter has the capacity to test hybrid or fully electric powertrains with up to 15 megawatts of available power.

- Powering up

In 2015, GE teams successfully extracted one MW of electrical power with an F110 engine in a ground-level test cell, followed by a 2016 demonstration of MW power extraction at flight-representative altitude conditions.

- Electric machine and power converter development

Shortly after a dedicated engineering team was formed at GE to focus on hybrid electric propulsion development, they demonstrated in 2016 an electric machine consisting of a MW-class motor/generator, electrically powering an 11-foot diameter propeller on a test stand.

- Component altitude testing

A component demonstration began in 2019 of a MW-class motor/generator at altitude conditions up to 36,000 feet at NASA’s NEAT facility in Sandusky, Ohio. GE believes this was the world’s first power dense, MW- and kV- class electric machine tested at flight-representative conditions.

- EPFD contract award

NASA announced in September 2021 a new research partnership with GE to launch a hybrid electric technology demonstrator program. After years of maturing individual components of a hybrid electric system—motors, generators and power converters—GE will systematically mature an integrated hybrid electric powertrain to demonstrate flight readiness for single-aisle aircraft. Plans are to conduct ground and flight tests of the hybrid electric propulsion system by the mid-2020s using a modified Saab 340B testbed and GE’s CT7 turboprop engines.

The most recently completed altitude integration test announced at Farnborough tested components independently and as an integrated system. Additionally, multiple operational modes were evaluated, including power transfer from side to side, power assist to a simulated engine, and aircraft power generation. The implementation of energy storage was also simulated.

The components used in the most recent altitude integration test have now been tested for thousands of hours since 2016 across sub-component, component, sub-system and system-level testing.

https://www.youtube.com/watch?v=jBu9g6kab9M