Five Facts About GE Aerospace’s Fastest-Selling Engine: The GEnx

December 2, 2025 | by Cole Massie

In the mid-2000s, airlines around the world could see the global aviation market expanding. Knowing they had to meet the new demand, they were eager for improvements in three key areas: fuel efficiency, durability, and reliability — especially when it came to long-range, widebody aircraft. To deliver that aircraft, airframers needed engine makers to produce a step-change in engine technology.

Boeing responded with its 787 widebody aircraft, known as the “Dreamliner.” And GE Aerospace responded with a high-bypass, high-thrust, and more fuel efficient engine called the GEnx. The pairing of the GEnx engine with the 787 has been a success, to say the least.

The GEnx stands as GE Aerospace’s fastest-selling high-thrust engine to date and powers more than two-thirds of all Boeing 787 aircraft currently in operation. It also earned a spot underneath the wings of the Boeing 747-8, the final iteration of the legendary 747 family of aircraft. Today, there are nearly 4,400 GEnx engines in service or in the company’s production backlog — a testament to the aviation world’s overwhelming response to a new era of turbofan technology.

As the GEnx celebrates its fifteenth year of service in 2026, here are five things you should know about this groundbreaking engine.

Big Brother, Little Brother

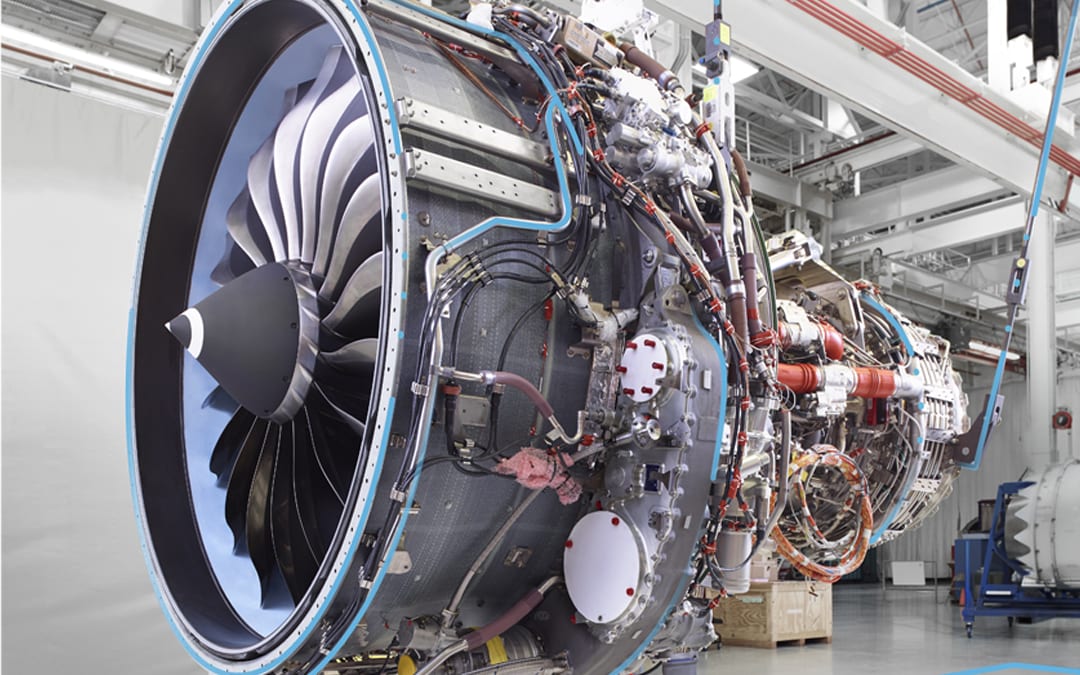

In jet engine design, lessons learned during research and development are passed down from one product to the next. The GEnx engine is no exception. In fact, during its development phase, GE Aerospace engineers took to calling the engine the “little brother” of the GE90 engine.

The evidence is there for all to see. The GE90 engine was the first commercial jet engine to feature lighter, more durable carbon-fiber composite fan blades, a major visual departure from traditional titanium blades. The GEnx engine features the next generation of those iconic fan blades, using four fewer blades than the GE90 engine, for a total of 18, to produce up to 78,000 pounds of thrust.

Built for the Challenge

The long-haul flights the GEnx engine powers traverse some of Earth’s harshest environments. In particular, hot, sandy, and dusty environments seen in the Middle East and South Asia can pose a challenge to the finely-tuned rotating parts in an engine’s core.

GE Aerospace engineers have diligently worked on solutions over the GEnx’s nearly 15 years in revenue service, including redesigns of the stage 1 high-pressure turbine blade and specialized durability coating for the combustor. These sophisticated upgrades to the GEnx’s high-pressure turbine (HPT) blades and more resilient coating technology for the combustor have more than doubled the GEnx engine’s time on wing in harsh environments. In November, a GEnx engine that has been operating since 2021 in the Middle East surpassed 4,000 cycles with the new HPT blade design.

GE Aerospace’s 360 Foam Wash, an advanced cleaning process that removes dirt and debris from engines, has also enabled improvements in both durability and fuel efficiency.

Today, the engine boasts a 99.98% dispatch reliability rate and stays on-wing at a rate three times higher than competing engines.

Efficient from the Start

Boeing’s 787 Dreamliner is heralded for its advances in overall efficiency and fuel savings. A central piece of the Dreamliner’s efficiency story comes from its engines.

The GEnx engine has 1.4% better specific fuel consumption than the competition for a typical 3,000 nautical-mile mission. Since a significant portion of an airline’s operating cost is fuel, that 1.4% difference over time can result in substantial savings for customers.

The GEnx engine was designed with efficiency in mind from the start, offering 15% better fuel efficiency than previous GE Aerospace engines in its thrust class. Weight savings in the engine are driven by advanced composite materials in both the fan blades and fan case, as well as titanium aluminum blades in the low-pressure turbine.

A Star Performer

As the adage goes in sports, sometimes the best ability is availability. The same can be true for airlines and their engine fleets: It’s critical for airlines to know their engines can perform reliably.

The GEnx engine delivers, boasting 6% higher utilization over the past 12 months compared to competing engines. That 6% utilization translates to seven more days per year of aircraft availability — ultimately meaning fewer disruptions to airlines and their customers.

Playing the Long Game

In 2019, 49 passengers and crew became part of an aviation milestone when they spent 19 hours and 16 minutes aboard a GEnx-powered 787 that traveled non-stop for the 10,066 mile journey from New York to Sydney. The flight was part of Project Sunrise, a test flight operated by Australian carrier Qantas to study the effect of ultra long-haul flights on passengers and crew. The GEnx engine’s superior fuel burn and reliability were critical elements of that successful flight, demonstrating how the power it provides to the Dreamliner could create all-new route flexibility and revenue opportunities for airlines.

A separate GEnx engine-powered flight in 2023 showcased similar long-haul capabilities, flying from Charleston, South Carolina, to New Delhi, India — this time using sustainable aviation fuel (SAF). SAF’s use of alternative feedstocks and processes reduces lifecycle CO2 emissions compared to fossil-based fuels.