GE Aerospace Is Committed to Raising the Bar on Engine Durability

November 15, 2025 | by Chris Noon

Airlines expect their engines to be increasingly efficient fuel burners. Case in point: The GE9X engine boasts a world-record-breaking 134,300 pounds of thrust, while also being designed for 10% better fuel efficiency than its predecessor, the GE90-115B.

But they depend just as much on world-class durability. That’s especially true for Middle Eastern and South Asian customers, who need their engines to endure punishing conditions, including the fine dust particles suspended in the air above the regions’ deserts.

GE Aerospace is doubling down on durability innovation, utilizing rigorous testing and advanced technology. Right now, GE Aerospace engineers are conducting dust ingestion tests on CFM* LEAP engines, rolling out hardware upgrades to the GEnx-1B engine’s hot-section components, and applying years of research and test validation to advance the GE9X engine and the CFM RISE program — all with durability as the focus.

Mohamed Ali, senior vice president and chief technology and operations officer, explains that customers’ demands for durability align with FLIGHT DECK, the company’s proprietary lean operating model that prioritizes continuous improvement to serve customers.

Ultimately, working to improve durability is at the heart of the company’s purpose — to invent the future of flight, lift people up, and bring them home safely.

A Solid Base

“There is elegance in simplicity with the least number of parts,” says Ali. He uses the analogy of a well-designed house. “If the architecture is done properly, occasionally you’re going to have to fix a sink or update the appliances, but the house works and is functional.”

Take the GEnx engine, the high-bypass turbofan developed for Boeing’s 787 Dreamliner and 747-8 aircraft. On entering service in 2011, the engine embodied a major advancement in commercial aviation, offering up to 15% better fuel efficiency than its predecessor, the CF6 engine.

From this solid base, GE Aerospace engineers enhanced the GEnx engine’s durability for hot and dusty extremes. The approach included sophisticated upgrades to the GEnx’s high-pressure turbine (HPT) blades. “We actually moved some cooling holes by no more than the thickness of a few human hairs,” says Ali. Engineers also developed a special coating technology for the combustor, making it more resilient against dust and heat, and introduced GE Aerospace’s 360 Foam Wash to effectively remove dirt and debris from internal components.

It’s paying off. The hot-section upgrades have more than doubled the GEnx engine’s time on wing in harsh environments. In November, a GEnx engine that has been operating since 2021 in the Middle East surpassed 4,000 cycles with the new HPT blade design.

GE Aerospace wields its scale and experience for the upgrades, explains Ali. “You can’t arrive at that level of precision unless you have modeling and testing capability,” he says. “Replicating [field experience] cannot happen without these 2.3 billion flight hours that we have all around the world and our big installed fleet in the hot and harsh environments.”

One Giant Leap

When it came to the CFM LEAP engine, the high-bypass turbofan produced by CFM International, GE Aerospace engineers built on what they’d learned from the improvements made on the GEnx engine. On service entry, the LEAP engine boasted higher pressure ratios, higher temperatures, and higher bypass ratios than its predecessor, the CFM56 engine. Those capabilities enable the LEAP engine to complete flight legs that are 30% longer. However, hotter and dustier flying environments present a bigger challenge.

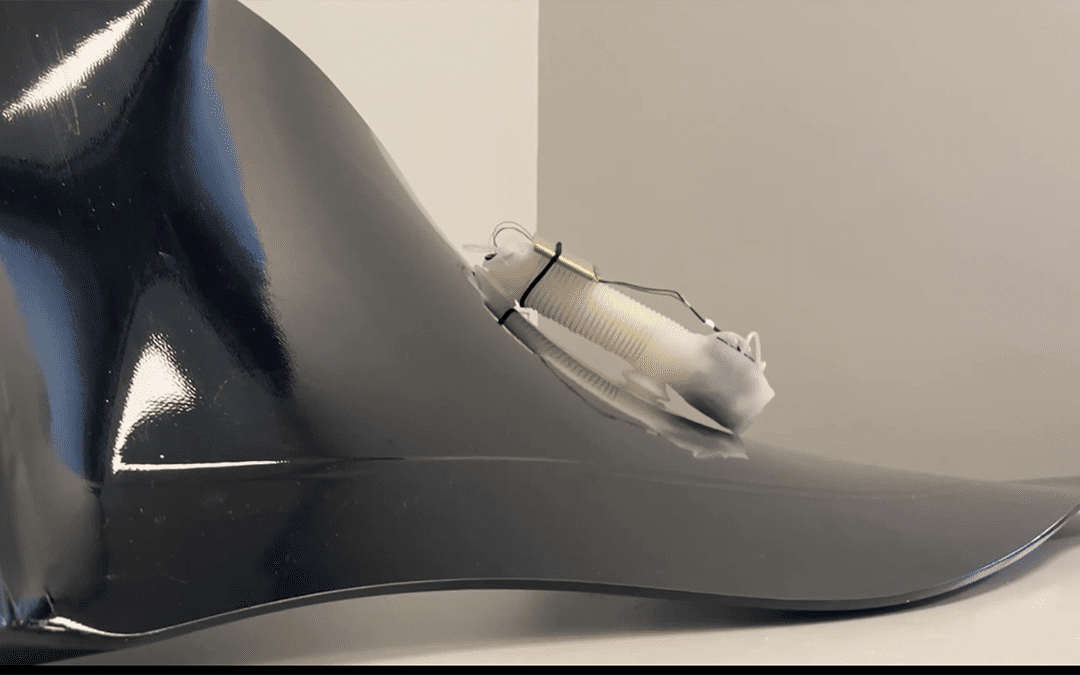

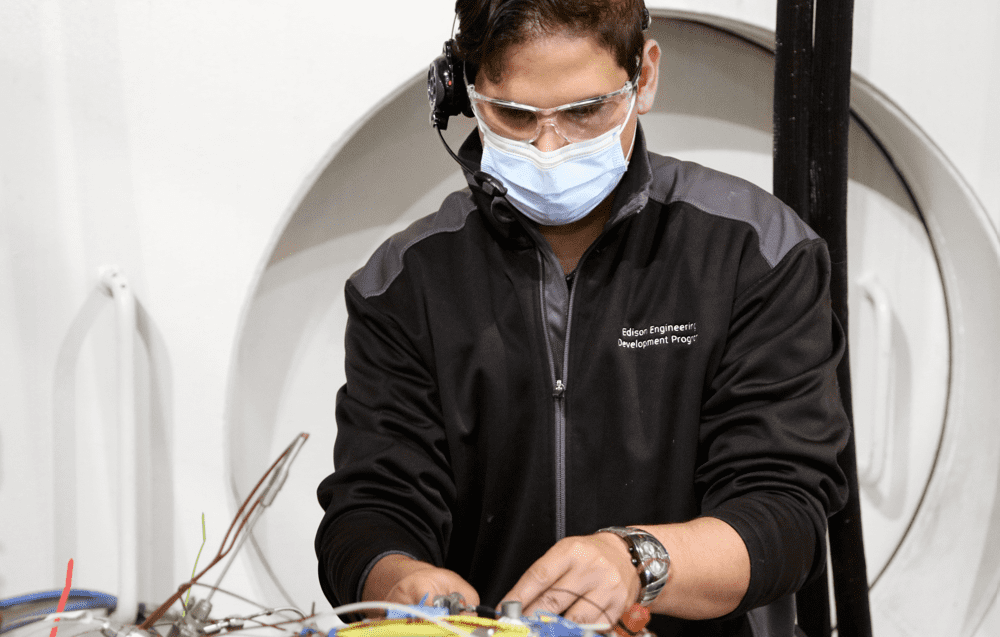

To meet it, GE Aerospace engineers are toughening up the LEAP engine with extensive dust ingestion testing, which simulates the volume, trajectory, and velocity of airborne debris that the engine might encounter in a typical journey over the Arabian Desert. It’s an effort that corrals around 15 years of lab work, thousands of hours of dust ingestion tests, and millions of hours of field data and advanced analytics from GE Aerospace’s other jet engine programs — and it’s leading to durability fixes in the field. Engineers also use what they call “turn on, turn off” techniques — running multiple engines for thousands of cycles, some with dust, some without dust, and others with hardware improvements — on test stands in Cincinnati, which allows for rigorous scientific control.

The approach is delivering results. Their fixes for a handful of parts are designed to more than double the LEAP-1A engine’s time on wing in severe operating environments. Similar gains are expected for the LEAP-1B engine in 2026. “The GEnx learnings have allowed us to introduce a better product quicker and reach maturity faster,” explains Carlos Perez, vice president of commercial engine systems engineering.

Testing, Testing

Engineers are also putting the knowledge they’ve gained over years of research into advancing new engine programs, such as the GE9X, the engine destined for the Boeing 777X. “Our goal was to start testing early and often, bringing in lessons learned from the GEnx and LEAP to improve maturity at entry into service,” says Alisha Kalb, commercial engine systems engineering executive leader.

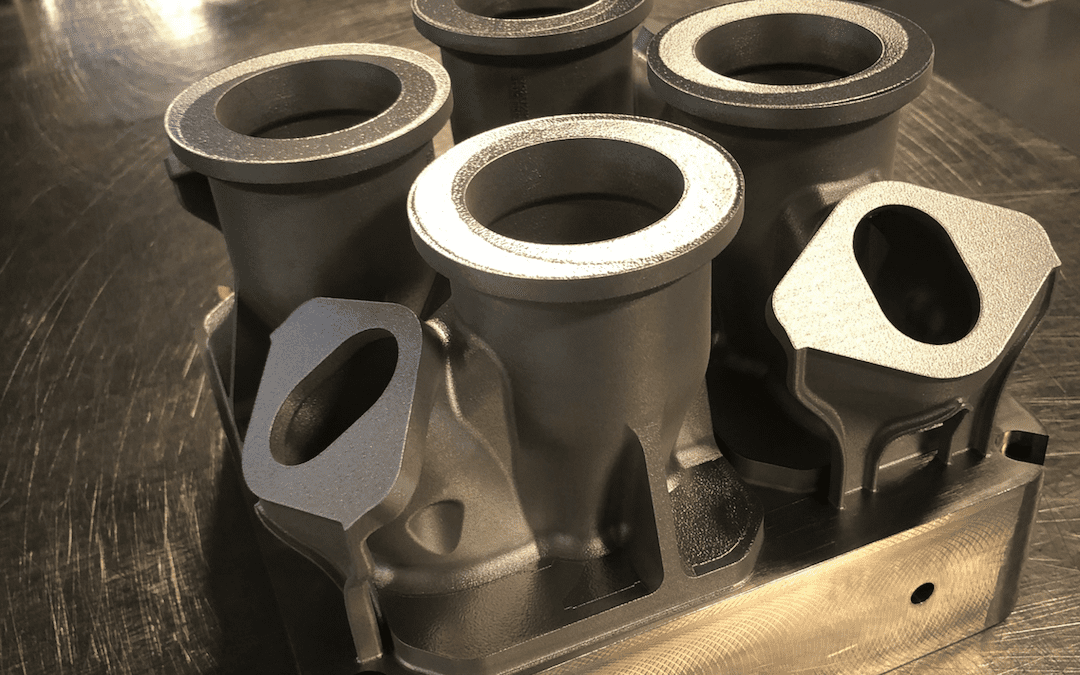

The GE9X, which will be the most tested engine program in GE Aerospace history when it enters service, has endured more than 30,000 cycles, including 9,000 endurance and 1,600 dust ingestion cycles. The extensive testing has helped to validate hardware and new materials, such as lightweight ceramic matrix composite parts and 3D-printed metal components, under increasingly harsh conditions. “We are not finished, and we are planning for more,” adds Kalb. Indeed, the GE9X engine is currently undergoing a second round of dust ingestion testing.

The durability lessons learned today are also propelling the future of flight. Engineers have already run more than 3,000 endurance cycles for hot-section blades and fuel nozzles on the CFM RISE technology demonstrator, advancing a suite of next-generation engine technologies like Open Fan architecture. And CFM has started dust ingestion testing on the RISE demonstrator’s high-pressure turbine airfoils, which is the earliest the company has ever conducted such tests in the technology development process.

Achieving durability gains while preserving the RISE demonstrator’s ultra-efficient fuel burn is well within reach, explains Arjan Hegeman, vice president of future of flight. “The middle part of the engine where you combust the fuel is a very hot part of the engine with very high airflow pressures,” he says. “But GE Aerospace has significantly advanced the technologies [using] ceramic matrix composites and other novel ways of cooling the components in the airflow path to [create] sustainable temperatures and get high durability.”

Open Fan architecture has some inherent advantages for durability, Hegeman adds. “In an Open Fan you can consider scaling back a little bit of your core performance because you have so much performance in that fan itself. So you can start delivering an engine that gives a lot of fuel efficiency plus significant durability improvement.”

Flying Longer

The Defense & Systems business has also made significant strides in performance and durability.

Since it first hit the market 40 years ago, 92% of the F110 engine’s parts have been upgraded with new material, new coatings, and an improved manufacturing and inspection process. What’s more, the F110-129 and F110-132 engine variants have been updated with Service Life Extension Program (SLEP) hardware upgrades. Advanced cooling technologies borrowed from the CFM LEAP engine now provide superior performance in hot and harsh conditions. And engine availability, or readiness, and reduced life-cycle costs have also been bolstered through improvements that have increased the lifespan of major rotating parts. All of this has helped the F110 achieve an industry-leading standard for time on wing — the average hours flown before an engine is removed from an aircraft for maintenance — of 750 hours.

Additionally, the T700 helicopter engine has accumulated more than 100 million flight hours in harsh conditions involving sand, dust, and extreme temperatures. Its design includes features like an inlet particle separator that spins out dirt, sand, and dust to help it perform in tough environments. GE Aerospace has continuously developed and improved the engine. The T700-GE-701D engine, for instance, features improved hot-section components that have doubled its durability, leading to a longer life.

In October, Larry Culp, chairman and CEO of GE Aerospace, reminded investors of the main stakeholder in durability innovation. “We are using technology to be customer-driven. We’re not satisfied because our customers are not satisfied,” he said. “That infiltrates everything we do throughout the design cycle, production, and into the aftermarket.”

It’s a message that is sure to resonate at this year’s Dubai Airshow.

*CFM International is a 50-50 joint company between GE Aerospace and Safran Aircraft Engines.