GE Aerospace’s F404: The Little Engine That Could — and Still Does

June 30, 2025 | by Cole Massie

GE Aerospace’s F404 engine has been around the block once or twice. Actually, maybe three or four times. In fact, nearly 20 different prototype, experimental, and production aircraft for militaries around the world have relied on the F404’s power over the past half century.

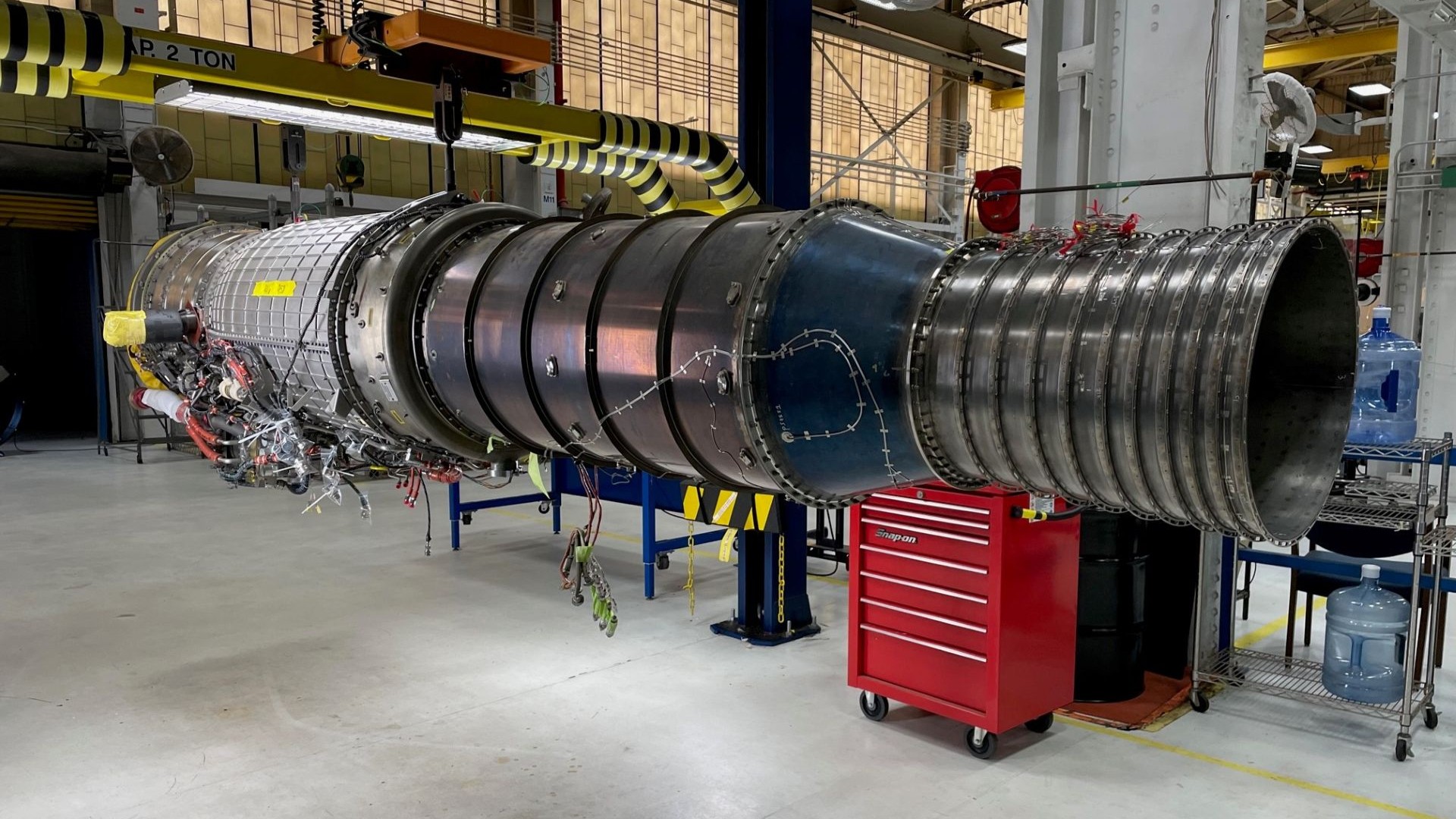

There’s only one F404, though, that has a story like engine serial number 946958. This singular engine has powered three completely different aircraft over its lifetime: the Boeing Phantom Ray, Northrop Grumman’s Model 400, and now Turkish Aerospace Industries’ (TAI) Hürjet. GE Aerospace can’t find a record of any other engine with this type of experience across three completely different aircraft test programs.

”What this engine really demonstrates is engineering and production quality, as well as flexibility and durability,” says Heather Caplan, director of international programs for both the F414 and F404 engines. “Those attributes have been the calling card of the F404 engine, and there’s no better example than this.”

Paul Cantin, whose first job at GE Aerospace was as an engine assembler, has worked with F404 engines for more than 40 years. Now a senior systems engineer, he’s been there through it all — from the mass-produced version of the F404 engine for the McDonnell-Douglas F/A-18 Hornet to the legendary F404-powered Lockheed Martin F-117 stealth fighter and now the program’s renaissance. Still, he’s never seen an engine quite like this one.

“It’s been pretty remarkable,” Cantin says. “I helped build this exact serial number engine back in 2009 for the Phantom Ray, and to see where it’s gone and going now, it’s hard to believe. But that’s an F404 for you. It’s the Chevy small-block V8 of jet fighter engines.”

Ready for Duty

The story of serial number 946958 began in 2009, when it was purpose-built for Boeing’s stealth unmanned combat air vehicle, the Phantom Ray. Drawing on GE Aerospace’s experience powering the F-117 stealth fighter, this engine was built in a “dry” configuration — meaning that, to preserve its stealth properties, it had no afterburner. After completing its experimental flight test program successfully, it was shipped back to its birthplace, GE Aerospace’s facility in Lynn, Massachusetts, and stored in a climate-controlled shipping container for future use.

After biding its time for a few years, the engine got its second chance to grace the skies in 2016 as various companies vied for the contract to produce the U.S. Air Force’s T-X trainer. Northrop Grumman and Scaled Composites teamed up to offer the Model 400, or “Swift,” powered by serial number 946958, to train the next generation of Air Force pilots. Once the aircraft was finished testing, back to Lynn it went, presumably for retirement. (Coincidentally, an F404 engine with a different serial number powered the Boeing-Saab entrant for the same competition. The Air Force ultimately selected Boeing-Saab’s jet, known as the T-7A Red Hawk.)

But opportunity came knocking again in 2022. As TAI’s Hürjet light fighter program was racing toward its first flight test, it needed an engine that could overcome pandemic-induced global supply chain challenges. At that time, serial number 946958 was being prepped for a second tour of duty on Northrop Grumman’s Model 400 aircraft when the call came in to convert it for use on a Hürjet instead, to help meet customer commitments. This time, the Lynn team equipped the engine with an afterburner and shipped it off to TAI. The TAI Hürjet took to the skies in April 2023 under the power of an experienced engine — or, as Cantin likes to call it, “the little engine that could and still does” to this day.

“A Product They Can Count On”

Thanks to recent program wins, including the T-7A Red Hawk trainer and the TAI Hürjet, as well as India’s Tejas Light Combat Aircraft (LCA) and South Korea’s T-50 trainer, F404 production is surging. According to Caplan, the biggest enabler for the F404 engine’s comeback is its full authority digital engine control (FADEC) system, derived from the company’s F414 engine program.

A FADEC system interacts with the pilot’s commands digitally to optimize engine performance during the entire flight. Rather than “flying the engine,” as some fighter pilots used to joke about analog engine technology, they now get to fly the plane. The FADEC system helps the modern-day F404 engine stay relevant with increasingly sophisticated and digital-focused trainer and light fighter platforms.

“I wouldn’t even call it a second wind,” Caplan says. “It’s into an entirely new product life cycle. The F404 engine is just the right thrust class for trainers and light fighter jets. As the existing trainer/light fighter class of aircraft around the world reach the end of their useful lives, our customers are looking to refresh their fleets, and we’ve got a product they know they can count on.”

For Cantin, getting serial number 946958 out the door to power yet another successful customer flight test program brings things full circle in his career. “It’s definitely been unexpected,” he says. “Ten years ago, we were sort of in maintenance mode, supporting our existing worldwide F404 customers but not making new F404s. Now the F404 will be our highest-volume turbo-jet engine program in the entire Lynn plant, just like it was when I was assembling and testing them back in the 1980s.”

The best part for Cantin, though, is getting to pass along his extensive engine knowledge to the next generation. He’s recently taken some early-career engineers under his wing, teaching them the importance of getting up close and personal with the hardware. For instance, Kendall Giebelhausen, an Edison Engineering Development Program enrollee at the time, who was also assigned to the TAI Hürjet program, got the experience of not only learning how to build a flight test engine, but also how to reconfigure an engine for use on a completely different aircraft. “Even I learned a thing or two,” he says.

“These engineers coming out of college are whizzes with the digital design technology,” he says. “It’s an amazing skill set. I try to emphasize the importance of both, though — the computer can tell you a lot, but so can the physical engine. To me, that’s how you keep this program strong for another 40 years.”