Lean Learnings: How a Team in Abu Dhabi Slashed A-Check Time by 33%

July 31, 2025 | by GE Aerospace Reports Staff

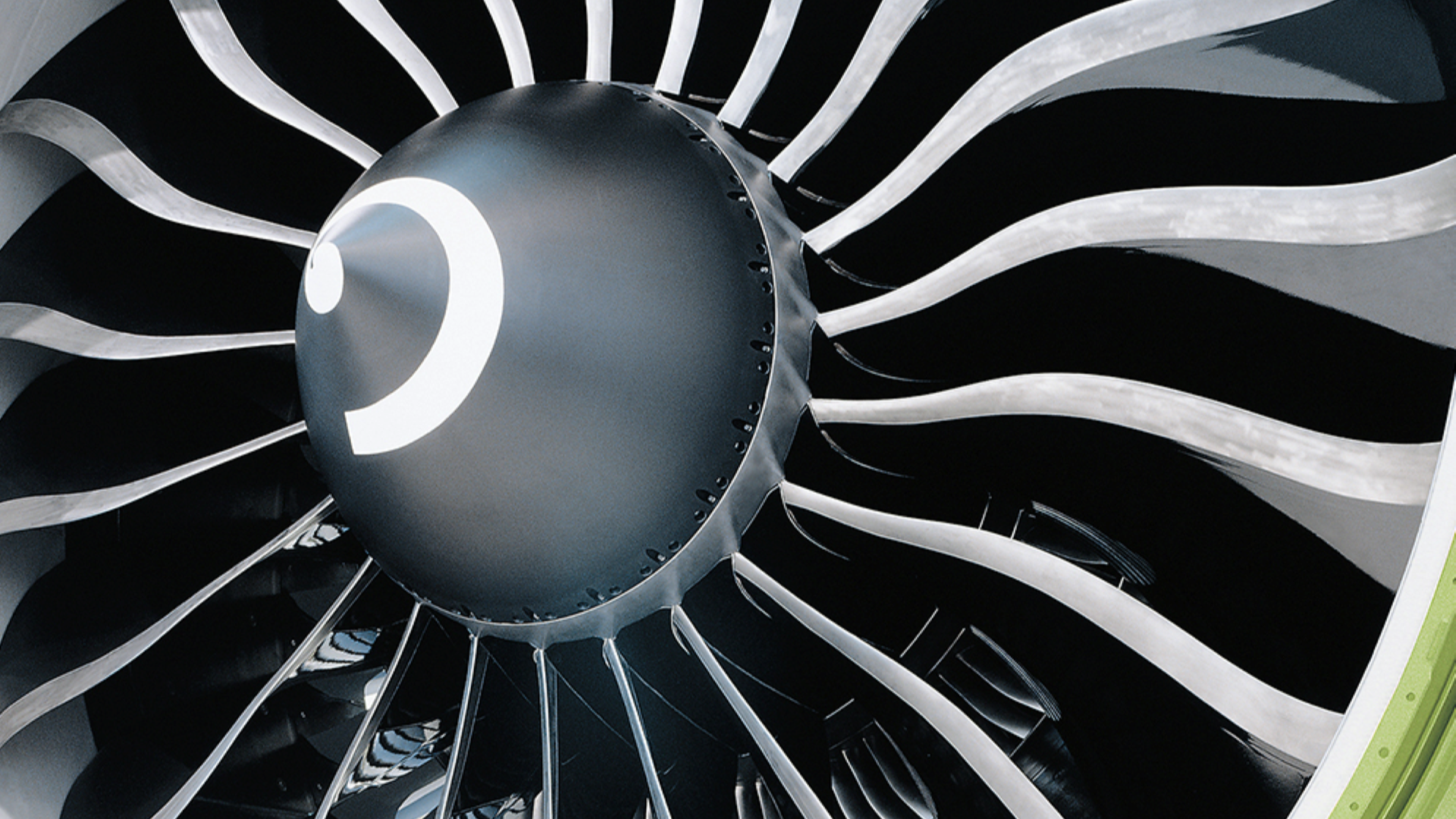

There’s nothing quite like a shiny new engine rolling out of the hangar, affixed to an aircraft and ready for takeoff. But like any piece of finely calibrated equipment, jet engines require precise and deliberate routine maintenance schedules, with services designed to get them safely back into the air.

That’s why GE Aerospace’s Customer Experience team works hand in hand with the technology centers and field services crews that coordinate engine maintenance around the world. This team helps maintain the safety, effectiveness, and efficiency of maintenance processes by focusing on continuous improvement.

At Zayed International Airport in Abu Dhabi, the team recently worked with Etihad Airways to optimize two key processes in the maintenance regimen for the airline’s fleet of 43 Boeing 787 aircraft. By applying the lean process known as “kaizen” — a Japanese term meaning roughly “change for the better” or “continuous improvement” — a pair of cross-company squads were able to improve the efficiency of the local maintenance program by a whopping 33%.

Safety First, Always

Commercial aviation is a highly regulated industry, with airlines required to perform and report both routine and non-routine maintenance. There is continuity in the fact that all airlines complete varying levels of maintenance (A-checks, B-checks, etc.), but what exactly is included in these checks varies based on airline, aircraft model, and engine type.

Etihad Airways’ fleet of 787s are equipped with GE Aerospace’s GEnx-1B engines. A-checks for these aircraft are performed approximately every 500 cycles, and for the GEnx-1B this includes a GE Aerospace 360 Foam Wash and borescope inspection (BSI), among other tasks.

Francisco Hernandez is a GE Aerospace customer lean leader based in Dubai. Bringing to bear his years of experience in lean — which GE Aerospace embraces through FLIGHT DECK, its proprietary lean operating model used to deliver exceptional value as measured through the eyes of its customers — Hernandez led the team in Abu Dhabi as they focused on optimizing the 360 Foam Wash and BSI processes.

Mapping the Value Stream

Launched nearly five years ago, GE Aerospace’s 360 Foam Wash is a deep-cleaning engine wash process in which a proprietary foam detergent is injected into the engine and subsequently rinsed. The method helps remove dust and dirt particles, which helps to lower engine exhaust temperatures and improve engine compressor efficiency — leading to improved fuel efficiency after the foam wash process. 360 Foam Wash can be performed while the engine is offline and on-wing.

One core concept of lean is to assemble a team at genba, meaning “the place where work is done,” so Hernandez and the team set to work on the maintenance floor. “It’s important to experience the process as it is,” he says, “and as it was, foam washing took 12 hours from start to finish. That included cycle time, which refers to the time it takes to complete the work, and lead time, which is the total time it takes for an item to make it through the process.”

The team created a value stream map — a visual representation of the foam wash process in which a sticky note represented each step in the 12-hour process. Mapping the current state allowed the group to zero in on waste and quickly identify areas where optimization was possible. Their biggest opportunities lay in prep work and tools. The solution is a dedicated foam wash tool-kit trolley with a shadow board for tools. Hose and power cable storage was reorganized, and the team worked with a supplier to optimize the existing foam wash cart. They implemented measures to ensure that the tablet used throughout the process maintained a battery charge and wireless connection.

With these improvements, the team cut four hours off the 360 Foam Wash process, a 33% efficiency improvement.

Optimizing Borescope Inspections

During the same 24-hour A-check window in which 360 Foam Wash is performed, technicians also deploy the GEnx BSI remote visual inspection tool. This device snakes its way through the innermost areas of the engine, capturing and processing images that technicians then review to assess the condition of the hardware.

Again working with stakeholders from GE Aerospace and Etihad Airways, Hernandez led a session observing the process in action. They created a current-state value stream map and found that inspection time varied depending on BSI technician experience. To tackle this, the team established dedicated BSI teams and made sure each team included at least one experienced technician.

Additionally, the group upgraded the borescope equipment software to give technicians better guidance on location and angle for image capture and rolled out a photo-tagging feature that expedited report generation. They also decreased BSI prep time by creating a BSI tool kit that includes all the parts and pieces that technicians might need throughout the process.

With these improvements, the team increased overall BSI process efficiency by 33%.

With these lean lessons learned, Hernandez is better equipped to tackle the next lean project with GE Aerospace’s commercial customers. “These kaizen exercises delivered amazing, quantifiable results for our customer that can be replicated from engine to engine and customer to customer.”