Parts Is Not Just Parts: GE Aviation Hungary Is Building an International Reputation for Excellence

September 19, 2019 | by Yari Bovalino

Budapest is known for many things—a profusion of Baroque and Art Nouveau architecture, beautiful old churches, hilltop museums and old school cafés serving up decadent pastries on the banks of the majestic Danube River. But did you know that the headquarters for GE Aviation Hungary is also situated just 18 miles north of this capital city, in the picturesque village of Veresegyház?

GE's presence in Hungary dates back more than 30 years and today counts almost 4,300 people working at four production sites (including Veresegyház) and three R&D centers. The Power division has the largest presence, followed closely by Aviation and Healthcare; Digital Solutions and BHGE (once known here as Oil & Gas) are also present. "We often collaborate not only with our neighbors in Power, but with all the other businesses,” says Casey Ott, site leader of GE Aviation Hungary. “We share best practices, indicators, objectives and, in particular, a network of relationships with suppliers in the region.”

Ott began her career as a manufacturing engineer at Aviation's global headquarters in Evendale, Ohio, before going on to gain important experience at GE’s aerostructures business in Hamble, UK. She has only been in Veresegyház for 18 months but feels fully connected to the network of suppliers and team members that make up the burgeoning aviation eco-system in Eastern Europe. “The teamwork between GE leaders helps us a lot, even with personnel management and talents from abroad, without trodding on relationships with suppliers from both Hungary and other Eastern European countries,” Ott says.

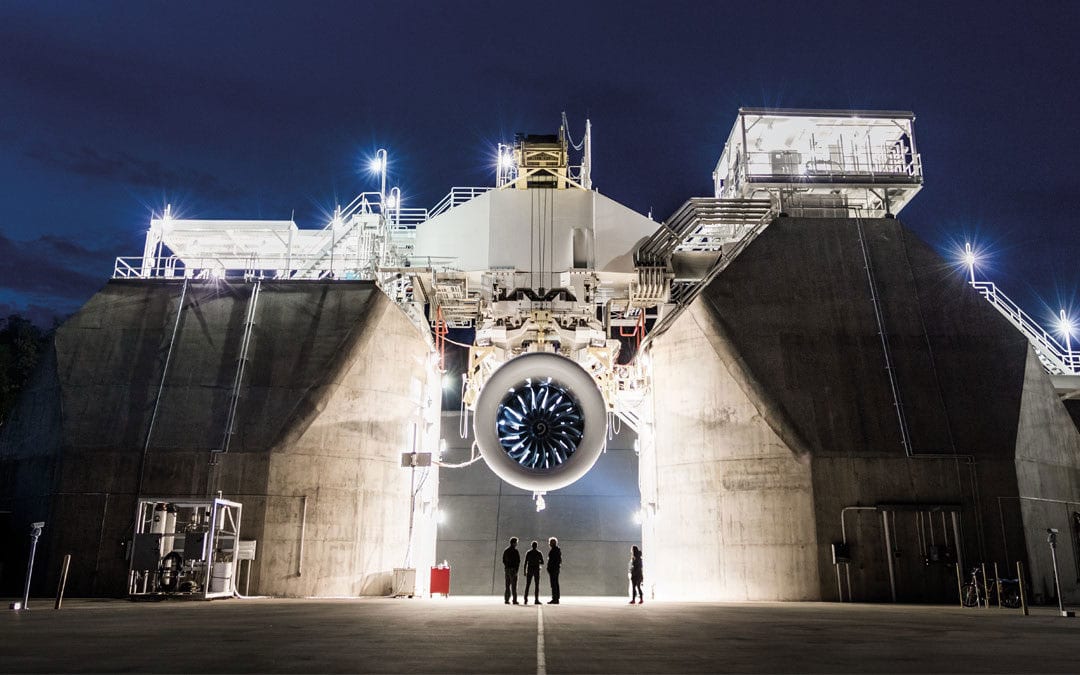

When it comes to the repair and maintenance of highly specialized aircraft engine components, GE Aviation Hungary has an international reputation. Name an airframe or an engine and odds are the team in Veresegyház has worked on it—from the Boeing 787, 747, 737 and 767 to the Airbus A300, A330 and the A320 family, as well as GE’s CF6, CF34, GE90 and GEnx and CFM International’s CFM56 and LEAP.*

In addition to working on high and low pressure turbines and high pressure compressors, the Hungarian team are experts in machining and repairing spinner cones and fan blades, as well as the composite panels that surround the blades and help to reduce noise emissions with their honeycomb structure. You could say they work on real works of art: Since 2007, the GE90-115b composite fan blade has been on display at the MOMA in New York.

The campus in Hungary is nearly 20 years old and over the last two years has welcomed over 100 new workers. “The year 2019 began with a 15 percent growth in the employee population, especially in the shop—so, experienced technicians,” explains Eva Prukner, HR Leader of GE Aviation Hungary. “One aspect we concentrate on is diversity and the work-life balance. We encourage managerial roles for women in the factory and are happy to have hired the first female welder a short time ago. We have also promoted a series of welfare initiatives for employees, which we often share with other Hungarian GE sites.”

Veresegyház is hooked into GE Aviation's global service network. It serves more than 170 customers worldwide, but 60 percent of the total volume of work in the shop assists GE Aviation production and service centers in Europe and beyond. In fact, only two other GE Aviation service sites—in McAllen, Texas, and Singapore—have the same capabilities as Veresegyház.

As the senior logistics manager of GE Aviation Hungary, Illés Szemán frequently collaborates with GE Aviation colleagues at the service sites around the world. His deep experience as an aircraft technician and avionics and autopilot systems expert, along with his work in the airline industry in between stints at GE Aviation Hungary, is highly respected.

“Quality is central for us,” says Szemán, who returned to Veresegyház in 2005 to lead sourcing and support operations. “We are committed to ensuring competitive turnaround times for our customers. The components we work with are usually delivered in 18 to 35 days.” The evidence is easy to spot on the shop floor, where signs and infographics display lean concepts and parameters and teams gather to analyze and optimize their performance daily.

Off the shop floor, the offices in Veresegyház are colorful and welcoming, an inspiring place that attracts talent. “We work on improving repair technologies, as well as the materials and products that cross our lines,” says Tamás Tardy, a manufacturing engineer.

In 2017, Tardy received his degree in mechanical engineering from Szent István University in Godollo, just east of Budapest, but he started at GE Aviation while still in school.

“Finally I got my master's degree this year, but I've been working on the team since 2016,” he says. “I started as a cooperative intern thanks to a collaboration model between the company and Szent Istvàn University that allows integrating and completing the training of young people in the real technical world. We also collaborate internally with other international engineering centers, like Bangalore, or with European centers like the Engineering Design Center in Warsaw.”

GE Aviation in Hungary invests more than $2.5 million a year in people and technology, which is confirmed not only by its modern facilities and manufacturing lines but also by the well-being of its employees. Case in point: On the campus in Veresegyház there is a space set aside for children who, for a day or a few hours, need to accompany their parents to work.

It’s just another example of the forward-thinking ethos that permeates the whole place—and the opportunities it presents.

https://youtu.be/YN-vwo8wv4M

*CFM International is a 50/50 joint venture between GE Aviation and Safran Aircraft Engines.

GE's presence in Hungary dates back more than 30 years and today counts almost 4,300 people working at four production sites (including Veresegyház) and three R&D centers. The Power division has the largest presence, followed closely by Aviation and Healthcare; Digital Solutions and BHGE (once known here as Oil & Gas) are also present. "We often collaborate not only with our neighbors in Power, but with all the other businesses,” says Casey Ott, site leader of GE Aviation Hungary. “We share best practices, indicators, objectives and, in particular, a network of relationships with suppliers in the region.”

Ott began her career as a manufacturing engineer at Aviation's global headquarters in Evendale, Ohio, before going on to gain important experience at GE’s aerostructures business in Hamble, UK. She has only been in Veresegyház for 18 months but feels fully connected to the network of suppliers and team members that make up the burgeoning aviation eco-system in Eastern Europe. “The teamwork between GE leaders helps us a lot, even with personnel management and talents from abroad, without trodding on relationships with suppliers from both Hungary and other Eastern European countries,” Ott says.

Above: A welder works on an engine component at the GE Hungary shop in Veresegyház. Top: Daniella Publik, Production Team Leader, displays a GE Aviation spinner cone.

Above: A welder works on an engine component at the GE Hungary shop in Veresegyház. Top: Daniella Publik, Production Team Leader, displays a GE Aviation spinner cone.

When it comes to the repair and maintenance of highly specialized aircraft engine components, GE Aviation Hungary has an international reputation. Name an airframe or an engine and odds are the team in Veresegyház has worked on it—from the Boeing 787, 747, 737 and 767 to the Airbus A300, A330 and the A320 family, as well as GE’s CF6, CF34, GE90 and GEnx and CFM International’s CFM56 and LEAP.*

In addition to working on high and low pressure turbines and high pressure compressors, the Hungarian team are experts in machining and repairing spinner cones and fan blades, as well as the composite panels that surround the blades and help to reduce noise emissions with their honeycomb structure. You could say they work on real works of art: Since 2007, the GE90-115b composite fan blade has been on display at the MOMA in New York.

The campus in Hungary is nearly 20 years old and over the last two years has welcomed over 100 new workers. “The year 2019 began with a 15 percent growth in the employee population, especially in the shop—so, experienced technicians,” explains Eva Prukner, HR Leader of GE Aviation Hungary. “One aspect we concentrate on is diversity and the work-life balance. We encourage managerial roles for women in the factory and are happy to have hired the first female welder a short time ago. We have also promoted a series of welfare initiatives for employees, which we often share with other Hungarian GE sites.”

Veresegyház is hooked into GE Aviation's global service network. It serves more than 170 customers worldwide, but 60 percent of the total volume of work in the shop assists GE Aviation production and service centers in Europe and beyond. In fact, only two other GE Aviation service sites—in McAllen, Texas, and Singapore—have the same capabilities as Veresegyház.

Illés Szemán, Senior Logistics Manager of GE Aviation Hungary, carries a GE90 fan blade in the shop.

Illés Szemán, Senior Logistics Manager of GE Aviation Hungary, carries a GE90 fan blade in the shop.

As the senior logistics manager of GE Aviation Hungary, Illés Szemán frequently collaborates with GE Aviation colleagues at the service sites around the world. His deep experience as an aircraft technician and avionics and autopilot systems expert, along with his work in the airline industry in between stints at GE Aviation Hungary, is highly respected.

“Quality is central for us,” says Szemán, who returned to Veresegyház in 2005 to lead sourcing and support operations. “We are committed to ensuring competitive turnaround times for our customers. The components we work with are usually delivered in 18 to 35 days.” The evidence is easy to spot on the shop floor, where signs and infographics display lean concepts and parameters and teams gather to analyze and optimize their performance daily.

Off the shop floor, the offices in Veresegyház are colorful and welcoming, an inspiring place that attracts talent. “We work on improving repair technologies, as well as the materials and products that cross our lines,” says Tamás Tardy, a manufacturing engineer.

In 2017, Tardy received his degree in mechanical engineering from Szent István University in Godollo, just east of Budapest, but he started at GE Aviation while still in school.

A repair specialist in Veresegyház inspects a CFM56 engine fan blade.

A repair specialist in Veresegyház inspects a CFM56 engine fan blade.

“Finally I got my master's degree this year, but I've been working on the team since 2016,” he says. “I started as a cooperative intern thanks to a collaboration model between the company and Szent Istvàn University that allows integrating and completing the training of young people in the real technical world. We also collaborate internally with other international engineering centers, like Bangalore, or with European centers like the Engineering Design Center in Warsaw.”

GE Aviation in Hungary invests more than $2.5 million a year in people and technology, which is confirmed not only by its modern facilities and manufacturing lines but also by the well-being of its employees. Case in point: On the campus in Veresegyház there is a space set aside for children who, for a day or a few hours, need to accompany their parents to work.

It’s just another example of the forward-thinking ethos that permeates the whole place—and the opportunities it presents.

https://youtu.be/YN-vwo8wv4M

*CFM International is a 50/50 joint venture between GE Aviation and Safran Aircraft Engines.