Still Going Strong: GE Aerospace’s CF6-80C2 Celebrates 40 Years of Changing the World

October 15, 2025 | by Jay Stowe

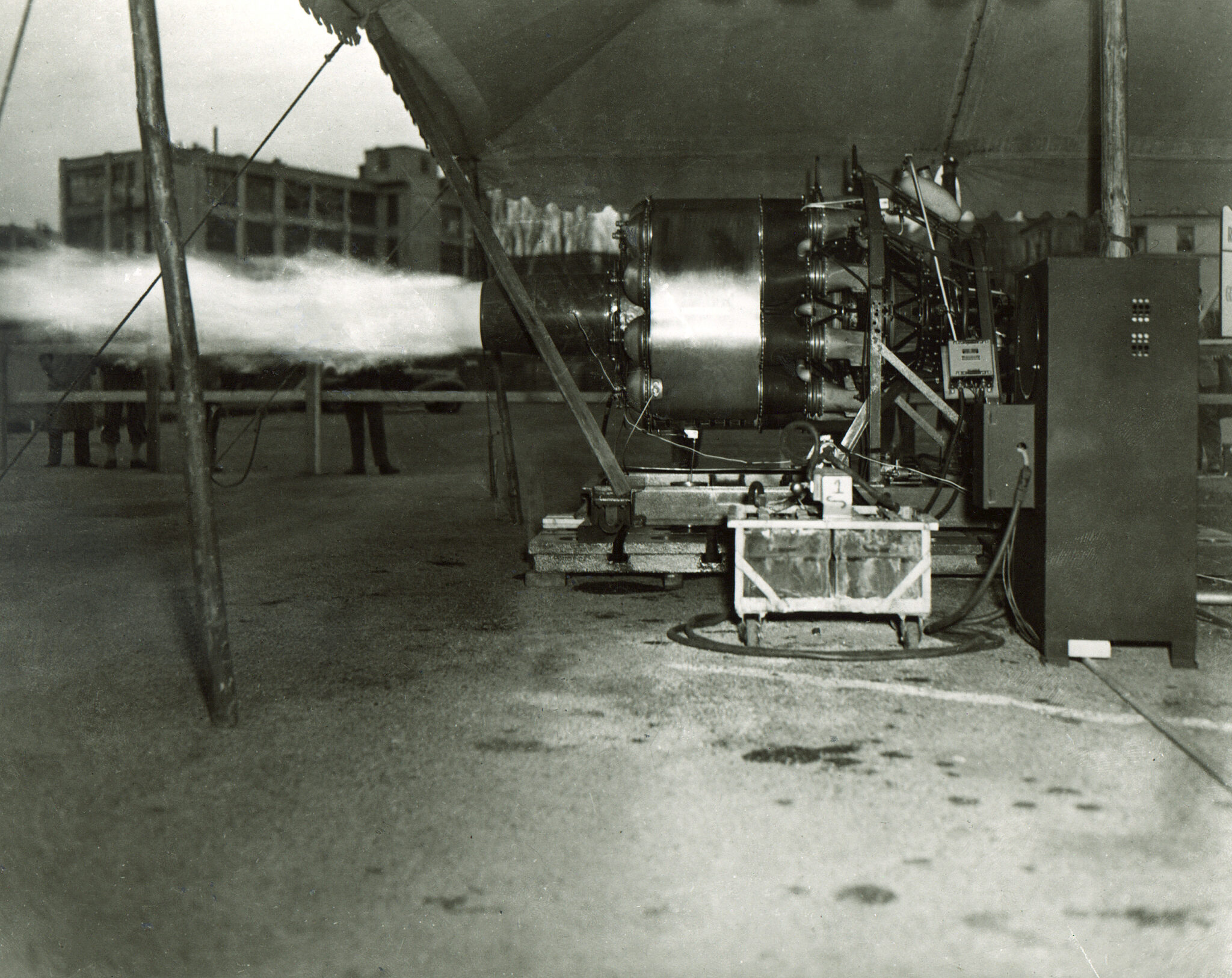

Success rarely comes all at once. It takes time. By any measure, the steady growth and longevity of GE Aerospace’s first high-bypass commercial engine line is the definition of success. Based on the technology of the TF39 military engine, the CF6-6 first entered service on the McDonnell Douglas DC-10-10 in 1971. Since then, the CF6 engine family has grown to include a slew of variants, from the CF6-50 and CF6-80A to the CF6-80C2 and CF6-80E1.

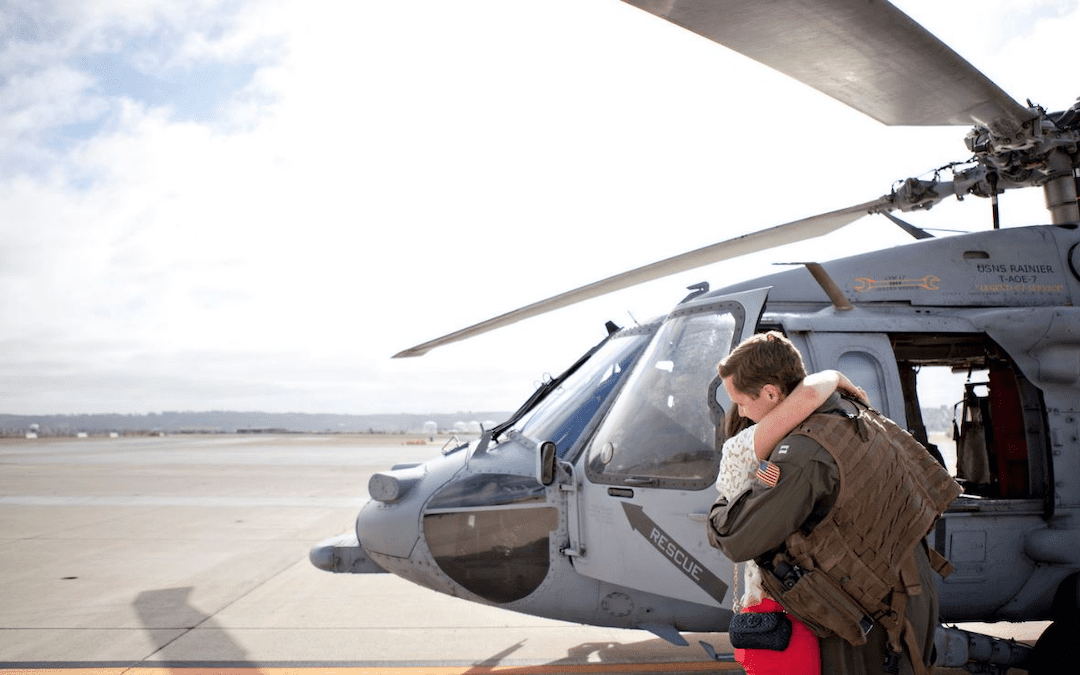

This month, the CF6-80C2 marks 40 years in service. Over that time, it has powered a wide variety of aircraft — carrying millions of passengers on commercial flights, millions of pounds of cargo on air freight flights, and a significant amount of personnel and matériel on military flights.

How pivotal a role has the CF6 engine family — and the CF6-80C2 in particular — played in the global air trade? Read on and find out.

Workhorse for the Global Air Freight Industry

GE Aerospace’s CF6 turbofan engines collectively power nearly 70% of the world’s widebody airplanes dedicated to hauling cargo. Since first entering service more than 50 years ago, the CF6 engine’s technology has advanced, earning a reputation for dependability and durability — which translates to an ever-ready fleet, on-time arrivals, and lower maintenance costs. As older passenger aircraft are converted into cargo carriers to meet the global increase in e-commerce, the demand for the enduring CF6 engine family has only grown.

“The CF6 engine is the secret sauce behind the explosive growth in air cargo, moving millions of dollars’ worth of commerce every day,” says GE Aerospace CF6 Program Leader Nate Hoening. “Whether it’s roses on Valentine’s Day or the newest iPhone, the CF6 has powered the transformation of global logistics.”

Largest Installed Base in Widebody History

Part of the longest-running jet engine program in commercial aviation, the CF6-80C2 has the largest installed base of any widebody engine in history. Since 1985, when it first entered service on Thai International Airlines, GE Aerospace has delivered 5,600 CF6-80C2 engines, 2,900 of which are still in operation. The CF6-80C2 is still being produced today for the Boeing 767 Freighter.

Powering Legacy Aircraft

The CF6-80C2 has powered a variety of commercial jets — including the McDonnell Douglas MD-11, the Boeing 767 and 747, and the Airbus A300 and A310 — and is the engine of choice for the U.S. Air Force’s largest aircraft, the Lockheed Martin C-5M Super Galaxy cargo jet. (The CF6-80E1 was designed specifically for the Airbus A330.) Since 1990, the CF6-80C2 has also powered Air Force One, and three -80C2 engines man the wings of GE Aerospace’s Boeing 747 Flying Test Bed, which is used for testing and certification of the company’s various engine product lines.

More Thrust, More Efficiency, More Time on Wing

Known for its high reliability, the CF6 engine family has continued to improve over more than five decades. Compared with the first CF6-6 engine, today’s engines are more powerful (nearly 70,000 pounds of thrust for the CF6-80E) and up to 15% more fuel-efficient, and they support three times more flights between overhauls. When it was introduced in the 1980s, the CF6-80C2 engine received 180-minute Extended-Range Twin-Engine Operations (ETOPS) approval on the Boeing 767, as well as 138-minute ETOPS approval on the Airbus A300 and A310, which enabled twin-engine aircraft operations on international flights across oceans. All told, the CF6 engine family is approaching 500 million flight hours since first taking to the skies in 1971.