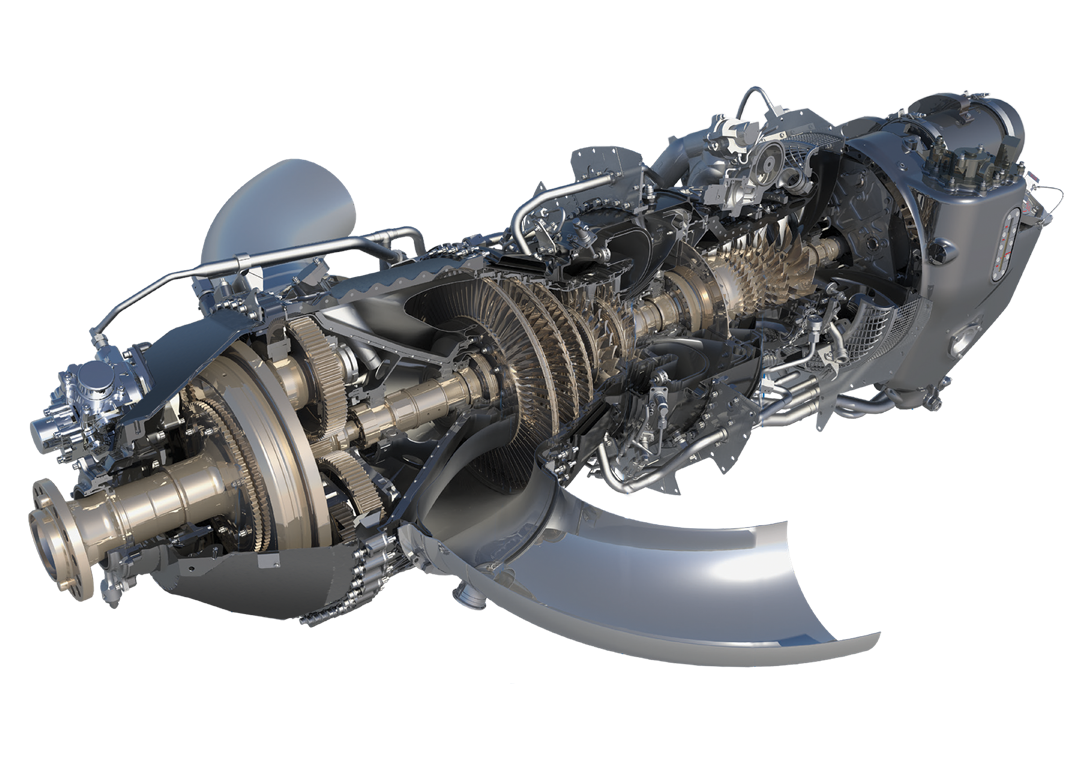

Catalyst engine

The power to explore

The Catalyst engine is the new advanced turboprop heralding a new era in business and general aviation. By utilizing technologies proven on GE’s larger commercial engines over millions of flight hours, it is balancing “all new” with “low risk and high value,” thus advancing airframer, operator, passenger, and pilot experience. The first business and general aviation application for the Catalyst will be introduced on the brand-new Beechcraft Denali.

A game changer

The Catalyst engine - aimed at the 1200-1400 SHP range - is the first modern turboprop ever built with 3D-printed parts, writing a pioneering chapter for the aviation industry. Avio Aero and GE’s engineers incorporated customer feedback into the engine’s design and development, for engineering design flexibility and a more pleasant, quiet, and sustainable journey for pilots and passengers.

The turboprop of the 21st century

Catalyst engine is the culmination of our commitment to extensive research and development, and advanced engineering with state-of-the-art technology and additive manufacturing componentry, ultimately delivering the best power-to-weight ratio in its engine class. This capability also allows for increased range, added payload, and a larger, quieter cabin.

Jet-like flying experience

The result is a simplified cockpit with a single-lever power control, fewer instruments to monitor and more precise engine controls. For pilots and their passengers this means a quieter and more enjoyable flight experience.

More efficiency, less emissions

A more fuel efficient, digitally-controlled engine opens a world of opportunities. The Catalyst engine benefits from GE’s engineering expertise and from the largest European research and development programs devoted to decarbonization. Additive technology has been used in combination with advanced alloys to allow more geometrical freedom in the design. The result is reduced fuel burn and weight, and in contrast, increased durability and efficiency.

Simplified ownership

Reliability is the benchmark of proven technology. This engine’s integrated digital features and GE’s analytics act as a technology liaison for maintenance prediction, prevention, and planning. The result is a greater availability and a lower cost of ownership for the life of the engine.