**EMBARGOED UNTIL JUNE 5, 2025 AT 6:00 AM EST**

Joe Vinciquerra, General Manager and Senior Executive Director,

GE Aerospace Research

Mohamed Ali, Senior Vice President and Chief Technology & Operations Officer, GE Aerospace

Inspection Tools

In the Shop

To maintain reliability standards during manufacture and assembly, technicians will immerse parts in water, pulse them with high-frequency sound waves, and analyze the sound reflections to look for anomalies that could be hiding inside the parts.

On Wing

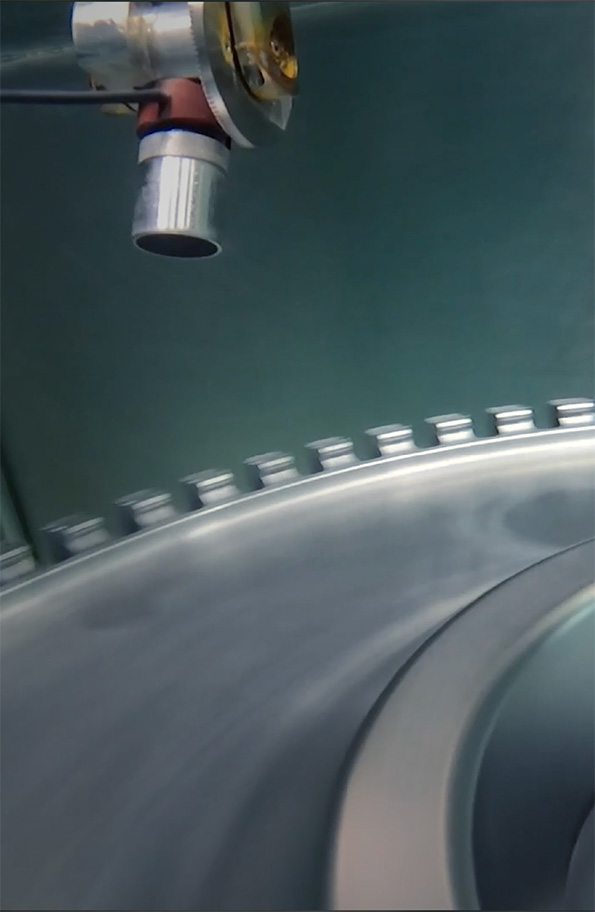

The Blade Inspection Tool (BIT) is equipped with an AI-enabled camera, which can be anchored into position to capture images of, for instance, high-pressure turbine blades during an on-wing inspection. The BIT counts and indexes each blade as it rotates into view, enabling technicians to compare and measure what they’re seeing, determine whether a blade is serviceable or not, and troubleshoot potential issues.

Off the Wing

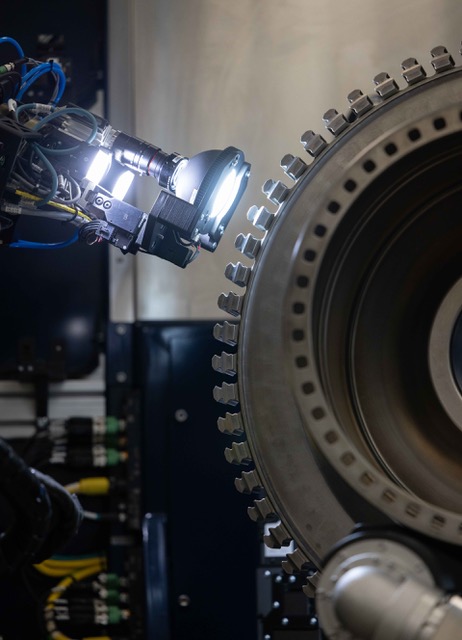

During a scheduled off-wing MRO visit, two articulated industrial robots outfitted with white light optical scanners will move closely over the surface of a high-precision part. Carefully choreographed by human operators, the robots use AI to capture and analyze data not visible to the naked eye with optimum accuracy, speed, and consistency, creating a digital record of the part’s condition.