Flow State: Using FLIGHT DECK to Overhaul a Production Line at Pune

November 24, 2025 | by GE Aerospace Reports Staff

It’s nearing lunchtime and Deputy Engineer Sachin Bhagat is in a quiet corner of GE Aerospace’s sprawling factory on the outskirts of the industrial city of Pune, India. While the rest of the shop floor is humming with its usual manufacturing rhythm, Bhagat is intent on bending a three-inch-diameter tube across two dimensions to test the limits of its shear, compression, and twisting stress.

Weeks of such well-thought-out trials and buy-in from supervisors and managers have worked out well for Bhagat and GE Aerospace. Last year, he and his peers came up with a fix for a recurring issue: how to eliminate the welding stage when joining two tubes together in a particular part. The process involved four manual stages, and each weld took about an hour, slowing down the production of this high-demand part.

The solution: replace the manual weld process with an automated bending process. As simple as it sounds, this was a complex operation that required a newly designed clamp and dies and heavier press machines.

The outcome: Not only did replacing the weld stage with a bend operation improve part quality and life, but it also raised productivity by 30%, eliminated non-value-added work (which freed up capacity for the welders), and resulted in a cost savings of over $150,000 a year. Additionally, this process improvement was adopted as a best practice and is now being utilized on six parts that used the same type of welding.

The innovation is but one of the scores of changes that have been put into place at GE Aerospace as part of its proprietary lean operating model, FLIGHT DECK. “FLIGHT DECK is how we translate strategy into operational and financial outcomes, as well as strategic breakthroughs, while advancing our culture,” the company noted in its 2024 annual report.

At the factory in Pune, FLIGHT DECK has jump-started operating efficiencies, leading to improved productivity, shortened lead times, and reduced waste. Abhijit Khandekar, head of operations management for manufacturing at Pune, spells out the new edge: “Predictable business is very important, operating cadence is very important, daily inputs and improvements are very important. FLIGHT DECK enables this.”

Focusing on SQDC While Transforming a Model Line

At GE Aerospace, safety comes first — always. One of the company’s key performance metrics is the injury and illness, or “I & I”, rate. To give an example of the depth of the focus on safety, every employee in the factory is empowered to “stop work” when a problem is detected. This, in turn, will stop the entire line. Employees may “stop work” to problem-solve, determine a root cause, or implement a countermeasure. It is a testament to the safety-first culture the team has created at Pune.

Beyond the importance of safety, FLIGHT DECK focuses on quality, delivery, and cost. To that end, the team has also been working to get the model line for the high-pressure turbine active clearance control (HPT-ACC) manifold up and running to serve as a guide for the rest of the site and show FLIGHT DECK in action. Since implementing the model line, the team has seen shorter lead times, increased productivity, less downtime, and a twofold increase in output since the beginning of 2023.

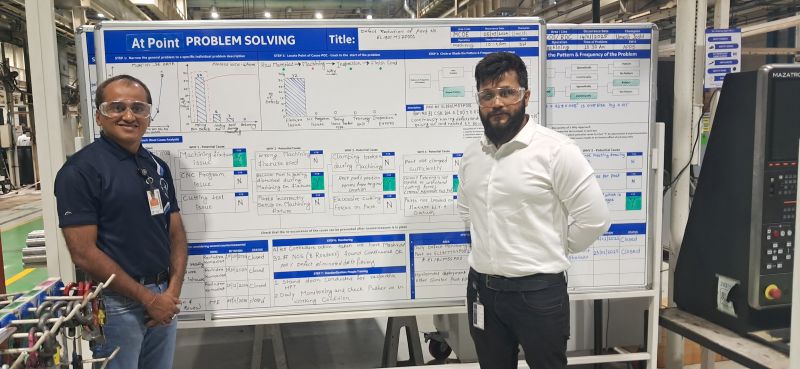

The transformation of the HPT-ACC model line, which produces components for the CFM LEAP* engine, started in the spring of 2023, and over the course of three separate kaizen events became a reality. During the kaizen events, subject matter experts from other GE Aerospace facilities served as fresh eyes, providing ideas and recommendations on how to go about implementing the changes. The first thing they did was streamline what Shashidhar Pai, FLIGHT DECK leader at Pune, calls a “standard work chart” — a visual representation of the movement of raw materials, parts, and work-in-progress products on the shop floor. Once they could visualize the hurdles, the team came up with a new layout that utilized a single-piece flow of parts sequentially.

Next they introduced automation, delivered in the right doses and customized to help human operators increase productivity. The steps they automated included: toggle clamping, utilizing one operator instead of two; reorganizing fixtures in a weld booth to eliminate changeovers when different parts come through (this resulted in a 20% savings in changeover time); and a cap-bending machine to reduce defects from five a day, when the process was done manually, to zero.

Komal Datir, a junior engineer who is shorter than most of her colleagues, said her favorite improvement on the new line is her tooling workstation, which can move up and down to adjust to the operator’s height. “Earlier, I had to lift it down to my level after someone else [had used it]. It’s heavy and it would strain my back,” she says. “Now I just need to press a button.”

Building on Success — from the Production Lines to the Canteen

The overhaul of the HPT-ACC line paid dividends in three stages. The parts-per-day output increased by 67% with the layout improvement, then by another 33% after a second kaizen event focused on design improvement, and by an additional 2.5% after a third huddle.

The HPT-ACC model line has been so successful that it is being replicated in other parts of the factory, which also produces components for the GE90, GEnx, and GE9X engine programs. “Our lead-time targets have come down significantly, meaning we can respond better to demand. We are going to transform the entire factory,” says FLIGHT DECK Specialist Pankaj Thakur. Work is already underway to streamline the fuel manifold and bracket cell production lines, with the goal of redesigning all the lines (including the tube line and press shop) by 2030.

FLIGHT DECK has made a significant impact in the Pune factory. The philosophy is so ingrained in the factory campus that even the canteen, which feeds more than 1,000 people, now measures itself according to SQDIP (safety, quality, delivery, inventory, productivity) metrics. “That’s the real thing,” says Pai, the FLIGHT DECK leader, with a chuckle as he walks out after an Indian lunch of rice, lentils, a small salad, sauteed vegetables, and dessert. “Even our caterer is measured by SQDIP. After all, he’s a vendor.”

*The LEAP engine is a product of CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines.