A Flying Start: Using Advanced Technology to Make the GE9X Engine as Durable as Possible for Customers

November 19, 2025 | by Chris Noon

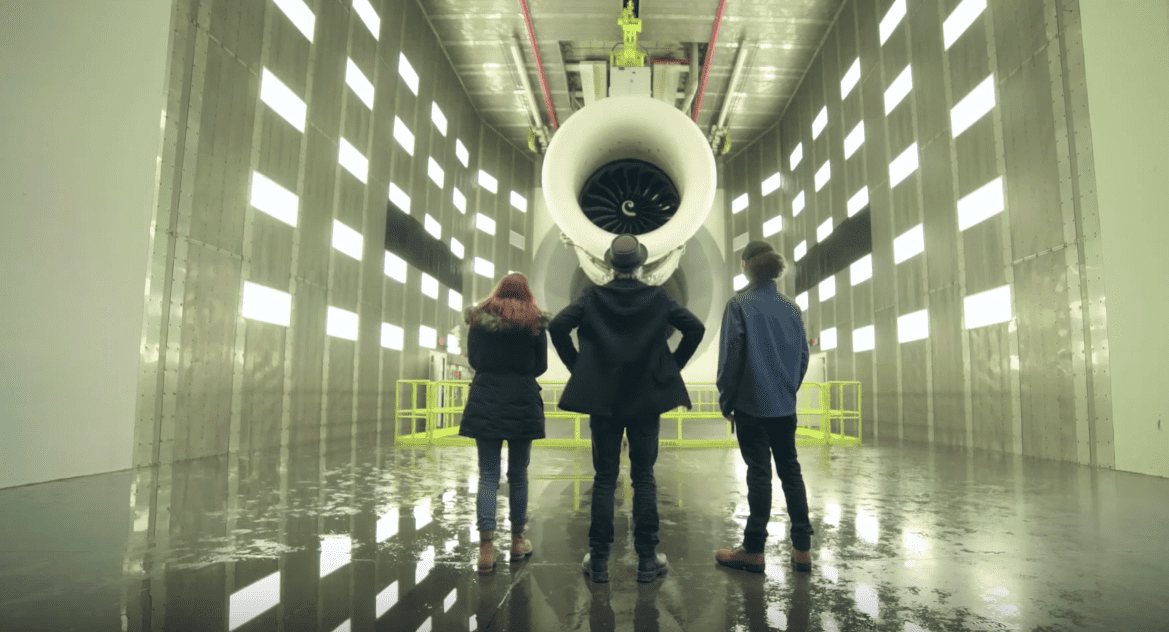

At this week’s Dubai Airshow, one of the biggest draws has been the Boeing 777X, Boeing’s new plane powered by the GE9X engine, the most powerful commercial jet engine in the world. Crowds have admired the sheer brawn of the GE9X engine, which has achieved 134,300 pounds of thrust, during flying displays of a 777-9 prototype. But Dubai is also an ideal place to talk about how the engine’s design has prioritized durability for hot and harsh environments, which has been enabled by GE Aerospace’s use of advanced technologies.

The engine has been built from the start with the Middle East in mind, explains Cristina Seda-Hoelle, who heads up GE Aerospace’s GE9X engine program. “Dubai is really important for this program, as two-thirds of the sales of the aircraft and engine have occurred from Middle East customers,” she says. To date, there are more than 550 orders for the 777X from 14 airlines. “We’ve been using our time [before entry into service (EIS)] wisely,” Seda-Hoelle adds, “continuing to test and iterate the design to ensure that when we launch this engine, it is as mature as possible for our customers.”

Settling into the Region

The GE9X is already GE Aerospace’s most tested engine in history. Seda-Hoelle notes that the company has applied cutting-edge technologies with a “test early, test often” philosophy. That’s allowed engineers to identify potential engine issues very early in the development cycle, make improvements, and validate the engine’s durability, efficiency, and performance in conditions that simulate real-world environments.

For example, engineers are currently putting the engine through a second round of dust ingestion tests. “In the past, we would have done this type of testing five to six years after EIS,” says Seda-Hoelle. During the tests, engineers are honing GE Aerospace’s proprietary testing and validation system, allowing them to “turn on” the dusty conditions unique to the Middle East, and then turn them off.

GE Aerospace’s Middle East Technology Center (MTC) team has also played an important role in the design and testing of the GE9X. Their work has included a multi-year project to gather dust samples from various sites across the Gulf, which helped GE Aerospace develop a proprietary dust that mimics the particles in the region’s atmosphere. This has enabled valuable insights about how dust accumulates inside engine components and impacts durability. The aim of all of this research and testing, says Carlos Perez, GE Aerospace’s vice president of commercial engine systems engineering, is to improve engine durability for customers, particularly in the Middle East.

To that end, the engine is set to receive an elite support squad in Dubai, too. GE Aerospace has just announced a new $50 million On Wing Support (OWS) site in Dubai South, a logistics hub near Dubai World Central airport. “One of the priorities is providing a world-class in-service experience for our customers,” says Seda-Hoelle. The new site is four times larger than GE Aerospace’s existing OWS facility in Dubai South. It will support advanced technology development for the GE9X and the CFM LEAP engine, the narrowbody engine developed by CFM International, a joint 50-50 company between GE Aerospace and Safran Aircraft Engines, which entered service in 2016. Seda-Hoelle adds that it will also have MRO training facilities to enhance the local team’s capabilities and support customer training initiatives.

Standing on the Shoulders of Giants

The GE9X engine draws on the robust foundational architecture of the iconic GE90, the world’s first engine to deploy carbon-fiber composite fan blades in place of metallic ones, which allowed for weight savings and larger blades for improved bypass ratios. From this solid base, engineers have fed in “the latest and greatest technologies and innovations that deliver durable products for our customers,” says Seda-Hoelle.

Many of the technologies were first used in GE Aerospace’s other engine families, such as the GEnx and the LEAP. The GE9X engine now boasts more parts made of next-generation materials, called ceramic matrix composites (CMCs), that can withstand much higher temperatures than most metals. “In the LEAP, it was just the shroud [made from CMCs], so we’re making big advances,” says Seda-Hoelle.

GE Aerospace also drew on MTC’s data-driven analysis to inform the design of dust separator technology in the GE9X engine’s central combustor, which improves engine durability by keeping the engine’s cooling air clean.

Granular Detail

GE Aerospace has made painstaking preparations for the ongoing dust tests. Take, for example, that proprietary dust it shoots into the GE9X engine on the test stand. “We need to understand the unique chemistry and geology [of the dust] and understand the basic physics that are going on in the engine parts,” says Perez. “It’s probably the most expensive dust you’ve ever seen.”

The sophisticated “turn on, turn off” dust testing system provides valuable scientific control, and has yielded continuous evidence-based improvement. “Every time we run one of these tests, we learn something,” says Perez. “The things that we’re looking for are so minute in some ways, but they make such a huge difference.” Engineers will also be able to apply the insights to the company’s other jet engine families.

But learnings are a two-way street. Perez cited a recent design upgrade to a turbine blade on the GEnx engine, which entered service in 2011 on the Boeing 747-8 cargo carrier, followed closely by the 787 Dreamliner. He explained how engineers drew on unparalleled engine flight experience, advanced aerodynamic analysis, and a robust test validation process to identify and fix the issue. It took 15 years of research and work, and ultimately “the design change was around two or three widths of a human hair,” he says, but it resulted in a significant improvement in durability.

“These are small changes with big, big outcomes,” says Perez, noting that the design upgrade had more than doubled the lifetime of the GEnx engine’s turbine blade in the Middle East region. Such durability fixes will be introduced to the GE9X and other engine families. “We’re drawing on field experience from narrow and widebody applications and more than 2.3 billion flight hours to test and validate our products,” he notes. GE Aerospace will beef up its analytical ability for the GE9X engine by rolling out AI-enabled blade inspection tools that can cut inspection times in half for operators while improving the accuracy of inspections.

The various technologies are finding and eliminating defects from the GE9X engine even as production enters a steep ramp-up phase. “The critical point is not whether you can put the technology out,” explains Perez. “It’s whether you can validate it and ensure that it really works where our customers want it.”

Durability innovation is a customer-led mission, explains Russell Stokes, president and CEO of GE Aerospace’s commercial engines and services unit. “We’re making sure that we have the capability needed to be able to serve our customers and keep their fleets flying,” he says. “Delivering on-time departure, managing unscheduled removals, and delivering on the durability commitment that we’ve tied into the launch of this product.”

Adds Stokes: “We’ll keep measuring success the way our customers think about it, feel it, and value it.”