Nine for GE90! Milestone Moments from the Iconic Engine’s 30 Years in Service

November 10, 2025 | by Chris Noon

It’s fitting that this year’s Dubai Airshow opens on November 17. On that day, 30 years ago, British Airways Flight 223 took to the chilly, grey skies over London’s Heathrow Airport, and landed in the clear warmth of Dubai International Airport around seven hours later. It wasn’t just another flight: Making its commercial flight debut under the wings of a Boeing 777-200 jet was the mighty GE90 engine.

Three decades on, and this iconic engine has carried millions of people and tons of cargo across the world, while rewriting the rules of widebody flight. The GE90 engine’s sheer power and efficiency opened a new era of twin-engined commercial aircraft. It has served as the springboard for a succession of groundbreaking innovations, from carbon-fiber composite blades to highly intricate 3D-printed parts. And it’s survived setbacks and bested rivals, establishing a remarkable 99.98% dispatch reliability rate in the process.

On the 30th anniversary of the GE90 engine’s entry into commercial service, here are nine moments, milestones, and marvels from its extraordinary journey.

Groundhog Day Drama

The giant high-bypass turbofan aircraft engine was officially declared airworthy by the Federal Aviation Administration (FAA) on Friday, February 2, 1995: Groundhog Day. While government officials pored over the certification documents in Evendale, Ohio, a twin-engine Boeing 777 awaited its flying orders on a runway in Seattle. Within hours of the FAA’s all-clear, the airplane made its first test flight bearing the engine. By November 12 of that year, the first GE90-powered 777 was delivered to British Airways.

A Big Bet Pays Off

The GE90 engine was a big bet by the former GE Aerospace CEO Brian Rowe and Boeing that large jetliners could fly long-distance, international routes with just two engines, instead of the usual four, thereby reducing both fuel and maintenance costs. It’s safe to say that their bet paid off. The GE90 engine and the Boeing 777 have since reinvented the logistics, economics, and aesthetics of commercial jet travel.

Undisputed World Champion

The GE90 was more than capable of the extra-heavy lifting demanded by twin-engine flight. It set world records for sustained thrust, peaking at 127,900 pounds in 2002, a figure that rivaled rockets from the Space Age. And it chalked up more than 15 years as the undisputed heavyweight champion powering the Boeing 777-300ER and 777-200LR.

Raising The Bar

As flying with two engines became the norm, the GE90 engine raised the bar on safety standards. The high-performing engine pushed Extended Twin-Engine Operations (ETOPS) to nearly six hours of safe flight on a single engine.

Going The Distance

The certification of the GE90 engine reshaped long-haul travel as we know it. With the 777-300ER, airlines could safely serve new, far-off destinations, all while yielding healthy profit margins and lower maintenance costs. British Airways was the first to field the GE90 engine in 1995, but more than 70 airlines worldwide have since followed suit. Dubai to London Heathrow is a classic route, with Emirates, the world’s largest GE90 operator, boasting almost 50 flights per month.

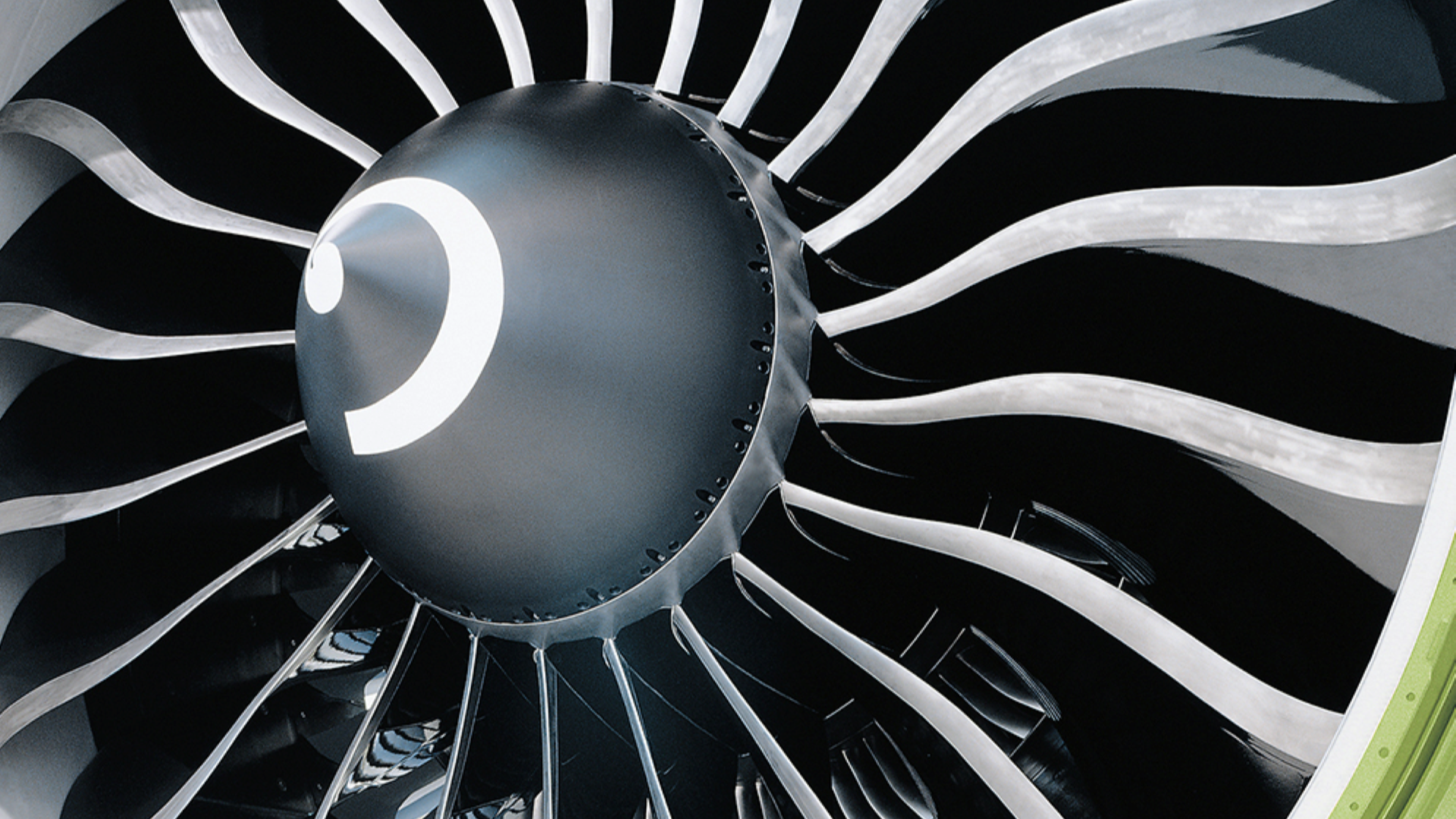

A Design Icon

The GE90 engine has always had a penchant for the avant-garde. It was the first engine to deploy carbon-fiber composite fan blades in place of metallic ones, which allowed for weight savings and larger blades for improved bypass ratios. No other engine maker has matched this design; the fan blade was so ahead of its time that New York’s Museum of Modern Art added one to its collection.

All That’s Print to Fit

Long before additive manufacturing went mainstream, the GE90 engine became the first commercial powerplant to sport a 3D-printed part, debuting a temperature sensor in 2015. The innovation immediately proved its worth, solving the engine’s ice build-up issues. It paved the way for its successor, the GE9X engine, which boasts dozens of 3D-printed parts that drive weight savings and other efficiencies.

All Hail the O.G. Engine

The GE90 is much more than just an engine. It’s a veritable proving ground for advances that now define commercial aviation. Its architecture and mechanical design influenced subsequent generations, including the GEnx, CFM LEAP*, and Passport engines, as well as the new GE9X engine. Many of the cutting-edge features on those engines — from record power to composite blades to improvements in durability, especially in hot and harsh regions of the world — were first tested and introduced on the GE90 engine.

A Symbol of Resilience

The GE90 engine hit some turbulence the late-1990s. The program encountered stiff competition, technical setbacks, and a brutal aviation recession, among other challenges. Its remarkable turnaround, culminating in an exclusive deal to power Boeing’s game-changing 777-300ER, became industry legend.

More than 3,000 GE90 engines have rolled off the production line since 1995, recording approximately 22 million flights and more than 100 million flight hours between them. But the GE90 engine’s story is far from over. GE Aerospace continues to invest in the groundbreaking engine, helping to reduce its weight, improve fuel efficiency, and enhance durability.

Here’s to 30 years, and countless more journeys ahead.

*CFM LEAP engines are made by CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines.