GE Aerospace Announces Major Investments in Next-Gen Tech at Singapore Airshow

February 9, 2026 | by Cole Massie

Every two years, global aerospace and government leaders transform Singapore’s Changi Airport into the center of the aviation universe: the biennial Singapore Airshow. The show has become a premier event — not just for the aerospace industry in the Asia-Pacific region but also as a global showcase of the technology that could define the industry’s future.

Between the strategic partnerships and deals forged in the exhibition center and the latest technological exhibits on the tarmac (or flying over it), this year’s show featured a number of important announcements from GE Aerospace and its partners in Singapore and the greater Asia-Pacific region. Among them are innovative partnerships with Singaporean governmental entities to advance aerospace technology research and development, new investments to support both commercial and military customers’ maintenance needs in the region, and a new collaboration to study airport operations of Open Fan engine technology in development with CFM International’s RISE program.

Hot off the press from Changi Airport in Singapore, here are four new announcements from the show.

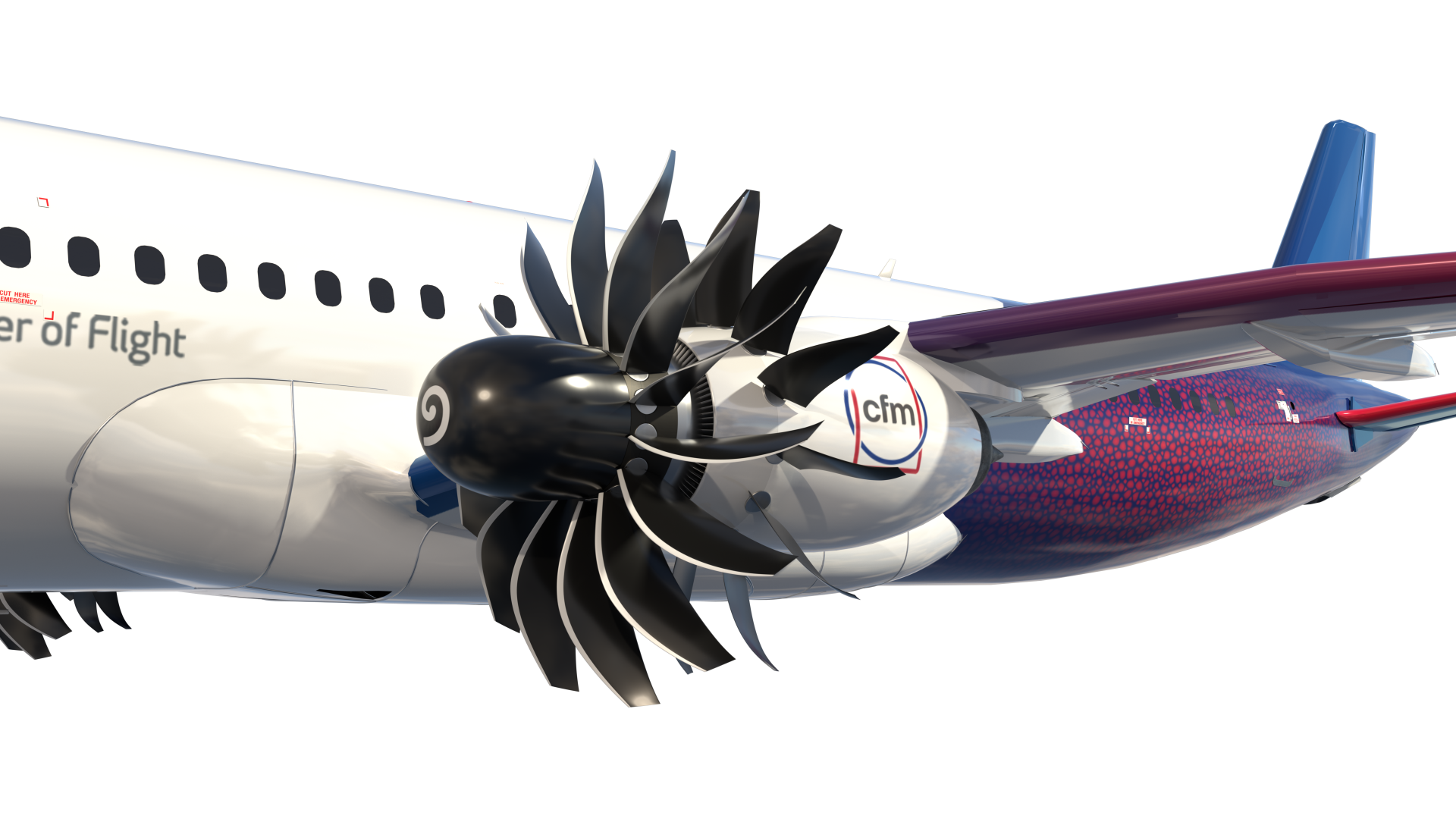

1. Laying the Groundwork for the RISE Program

In a world-first airport partnership, CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines, is teaming up with Airbus and the Civil Aviation Authority of Singapore (CAAS) to study the impact of Open Fan and other RISE program* technologies on overall airport infrastructure. This encompasses ground handling, maintenance, and more. The RISE program is a suite of demonstrator technologies aimed at producing at least a 20% improvement in fuel efficiency compared with today’s commercial engines. It includes the Open Fan engine design, which sheds the traditional ducts encasing the engine for improved efficiency with less drag. The study aims to develop a comprehensive readiness framework that could serve as the global blueprint for airframers, airports, and airlines worldwide.

“This first-of-its-kind agreement is a huge boon for the CFM RISE development program. These technologies are designed to deliver unprecedented improvements in fuel efficiency and emissions in a highly robust future product that can support demanding operations,” says Gaël Méheust, president and CEO of CFM International. “Now, having the ability to perform a real-world demonstration — from ground handling to maintenance actions to airport operations — will give airlines and, hopefully, the flying public confidence in the safety, durability, and efficiency of Open Fan technology.”

2. A $300 Million Investment in Singapore

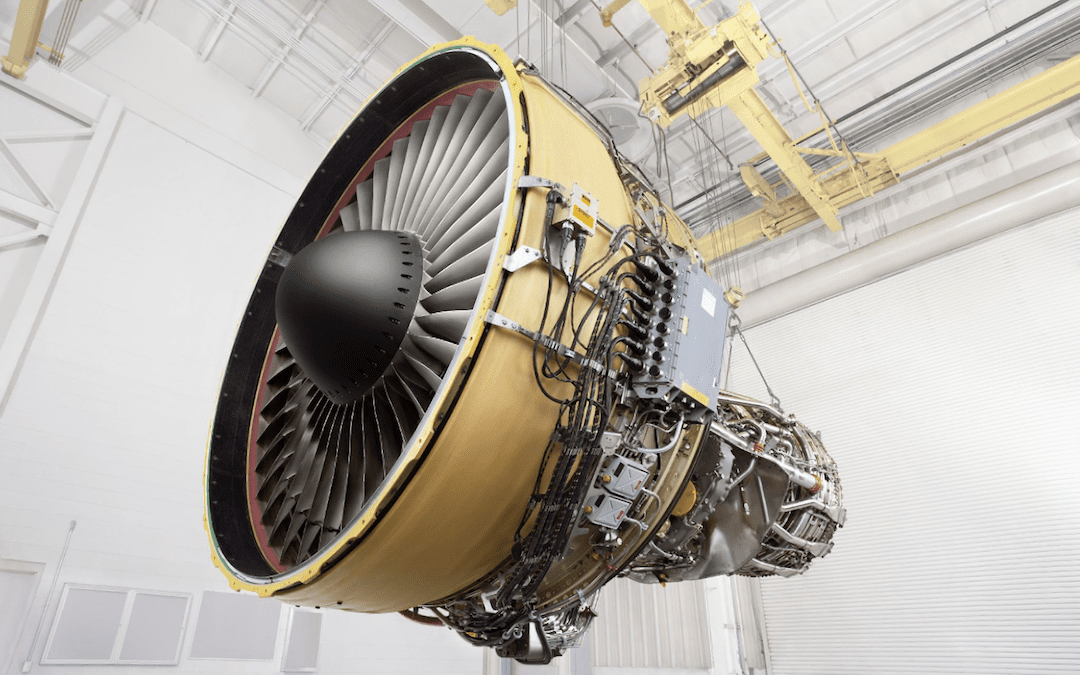

GE Aerospace announced a $300 million multi-year investment plan to bolster engine component repair capabilities in Singapore through 2029 — a continuation of the company’s commitment to growing its presence in the Asia-Pacific region. Supported by the Singapore Economic Development Board, the investment will transform engine repair operations, enabling faster turnaround times, improved connectivity, and a more seamless service experience for customers. GE Aerospace plans to establish an AI Center of Excellence to develop AI-enhanced and automated digital inspection solutions, as well as a new facility for REACH (Registration, Evaluation, and Authorization of Chemicals)–compliant coatings and the industrialization of such coatings, and a regional center for critical shaft repairs.

The company’s multi-year investment plan is already taking shape with the opening of a new module repair facility at Seletar Aerospace Park. The facility is dedicated to supporting the growth of CFM LEAP-1A and LEAP-1B high-pressure turbine (HPT) module operations. The investment is important to the global engine fleet in that it allows the company to execute work closer to operators in the Asia-Pacific and Middle East. In addition, by expanding HPT module repair for LEAP engines locally, the company expects to reduce turnaround times and improve engine flow across its global maintenance, repair, and overhaul (MRO) network.

“With the addition of Building 8 to our Seletar campus, we are not only expanding our physical footprint but also expanding our capabilities from engine component–level repairs to engine module–level work on the LEAP-1A/1B high-pressure turbine modules,” says Iain Rodger, managing director of GE Aerospace Component Repair in Singapore. “As the first of our focused module repair shops, this provides better connectivity within our engine overhaul supply chains, initially for Asia and Middle East MRO activity. Many of the components currently repaired in Singapore will be used within these modules, and the announced shaft repair capability will also feed into these modules, significantly reducing turnaround times for our customers.”

3. SPAARC: The New Hub for Aviation Brainpower

Ahead of the airshow, GE Aerospace teamed with the Civil Aviation Authority of Singapore, the Singapore Economic Development Board, and the International Centre for Aviation Innovation to officially launch the Singapore Partnership for Aviation Research and Capability (SPAARC), with the aim of accelerating next-gen aerospace research and development. The collaboration will pursue a wide variety of initiatives, including developing AI-powered decision-support tools for air traffic controllers and pilots to improve real-time decision-making. SPAARC will also focus on designing advanced analytical systems to plan flight routes better, optimizing airspace flow, capacity, and communication between airports, airlines, and flight crews; and explore novel engine designs to ensure that future propulsion systems integrate seamlessly with existing aircraft and airport infrastructure.

4. Strengthening Defense Ties with Thailand

On the defense side, GE Aerospace signed a memorandum of understanding with Thai Aviation Industries Co. (TAI) to explore military engine MRO support, including the possibility of TAI opening a dedicated MRO shop in Thailand to support the Royal Thai Armed Forces. The initial focus of the MOU will be on the T700/CT7, F404, and LM2500 engine fleets. The goal is to provide innovative in-country services that significantly enhance the availability of military fleets in a region where fleet modernization and optimization are a top priority.

*RISE is a technology development program. It is not a product offered for commercial sale.