GE Aerospace Research Center Celebrates 75 Years of Innovation

October 2, 2025 | by Christine Gibson

On a cold December morning in 1900, in Schenectady, New York, three GE employees embarked on a venture that would set a new standard for scientific research. When GE’s chief engineer Charles Steinmetz, chemist Willis R. Whitney, and engineer John Dempster arrived for work in Steinmetz’s barn — rechristened the General Electric Research Laboratory — they formed the nucleus of the world’s first industrial research team.

Over the next 125 years, GE’s lab pioneered technologies that transformed the company, revolutionized flight, and reshaped modern life. As the staff expanded, they moved through a succession of upgraded facilities, until 75 years ago, on Oct. 1, 1950, when GE opened the General Electric Research Laboratory’s current home in nearby Niskayuna, New York. In a ceremony attended by hundreds of people, company president Charles E. Wilson reaffirmed the lab’s bold mission: to equip researchers with the tools and technology to turn scientific discovery into innovation.

Seventy-five years later to the day, GE Aerospace celebrated the lab’s diamond anniversary and 125 years of groundbreaking research. As part of a ceremony hosted by General Manager and Senior Executive Director of GE Aerospace Research Joe Vinciquerra, the company unveiled plans for a new plaque on the building’s patio that will read “GE Aerospace Research: Front Door to the Future of Flight.”

As the staff of the facility, now renamed the GE Aerospace Research Center, continue to define the future of flight, they stand on the shoulders of giants who helped establish aviation as we know it. Here are a few of the remarkable discoveries from the first 125 years of innovation — including, fittingly for a diamond anniversary, the first-ever lab-grown diamonds.

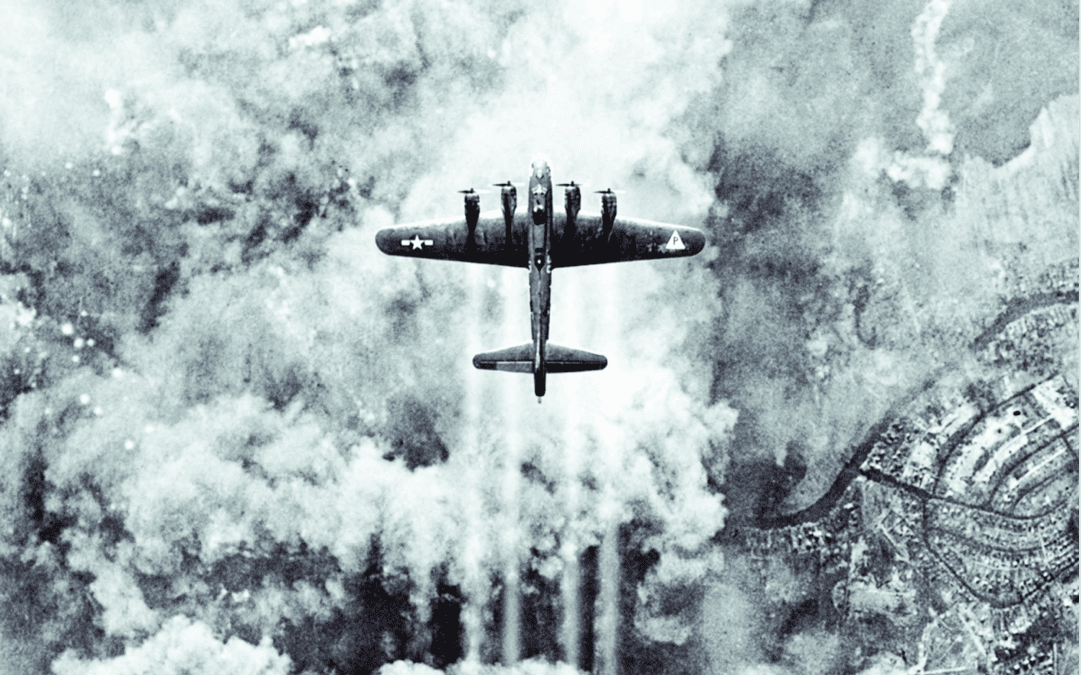

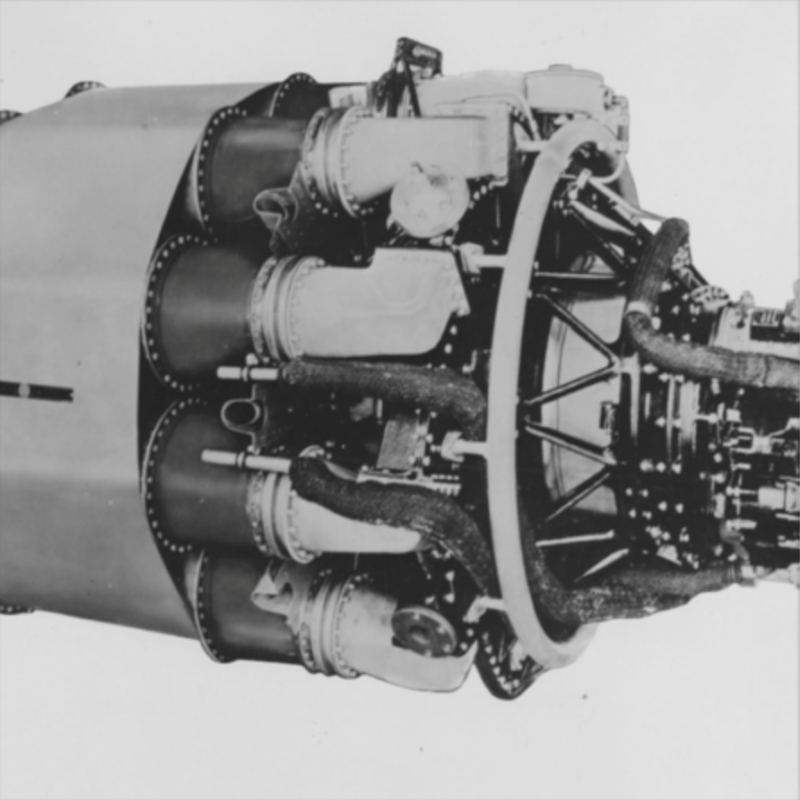

I-A: The First U.S. Jet Engine

On the eve of the United States’ entry into World War II, the Army Air Corps picked GE to build America’s first jet engine. GE was already supplying superchargers for Allied bombers, so the War Department wagered that the company’s experts had the know-how and talent to tackle the project. They were given six months. Working nonstop, GE engineers designed new parts, refashioned others, and delivered a top-secret prototype, called I-A, a month ahead of schedule. On Oct. 1, 1942, the first American jet plane, the Bell XP-59A, took off from Lake Muroc, California, powered by two I-A engines. The U.S. jet age had begun.

LEXAN Plastic

GE chemist Daniel Fox launched the modern era of engineering thermoplastics in 1953 when he first synthesized LEXAN polycarbonate resin, a material so tough that, to extract it, he had to chip away the glass flask he’d mixed it in. Permanently cemented to the end of a stirring rod, the sample was known around the research center as Dan Fox’s lollipop: an amber-colored glob that didn’t break even when employees hammered nails with it. Tough, durable, and heat-resistant, LEXAN soon became one of the world’s most widely used engineered materials, showing up in everything from the Apollo 11 astronauts’ helmets and fighter jet windshields to computer screens, water bottles, and flashlights.

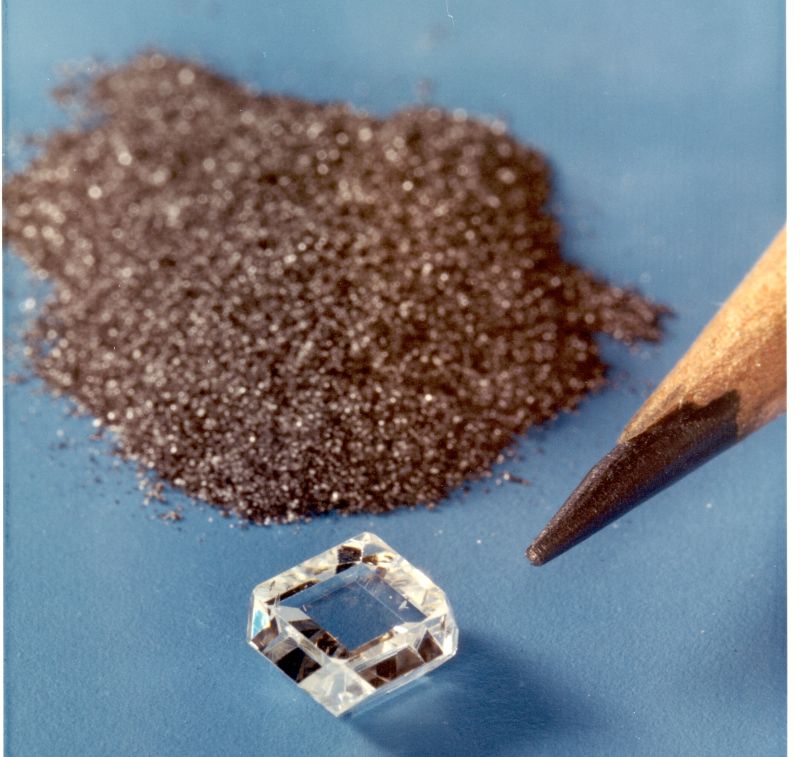

The Diamond Press

Diamonds form naturally only under the crushing pressures of Earth’s mantle. But in 1954, GE chemist H. Tracy Hall and three colleagues at the research center built a machine that marshaled those forces in the lab.

The company had been searching for a way to make diamonds on and off since 1941; as nature’s hardest substance, they are extremely valuable in industry. The “diamond press” the researchers built produced pressure of 1.5 million pounds per square inch and a temperature of 5,000 degrees Fahrenheit.

On the morning of December 16, 1954, Hall loaded this massive apparatus with a mixture of carbon and iron. After 20 minutes he checked the results. “My hands began to tremble; my heart beat rapidly; my knees weakened,” he would write in the scholarly journal The Chemist in 1970. “My eyes had caught the flashing light from dozens of tiny triangular faces of octahedral crystals … and I knew that diamonds had finally been made by man.”

J93: First Jet Engine to Hit Three Times the Speed of Sound

In 1957, GE won a contract to deliver a powerplant for the world’s largest bomber, the U.S. Air Force’s experimental XB-70 Valkyrie. In 1965, powered by six J93s, the XB-70 achieved Mach 3, three times the speed of sound, after being airborne for 62 minutes at altitudes above 70,000 feet. An aircraft of this size and weight had never traveled so high and fast. The first engine designed for speeds faster than Mach 3, the J93 introduced advances, such as air-cooled turbine technologies, that are still used in military and commercial engines today.

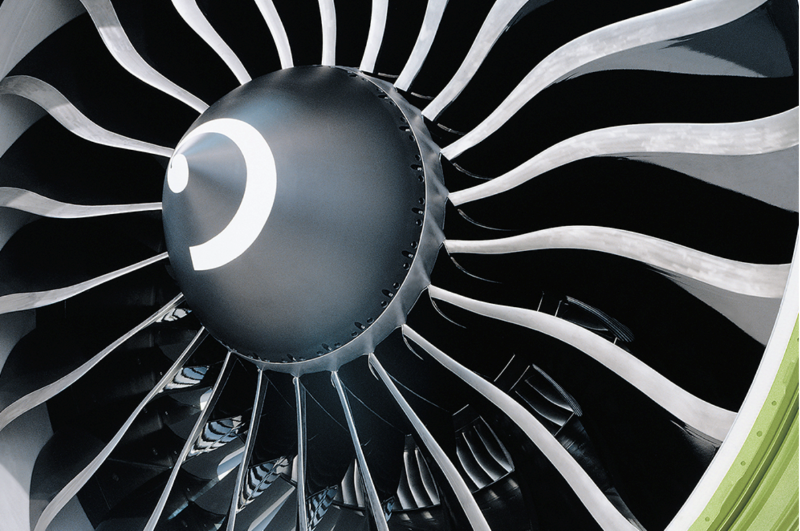

GE90: First Commercial Jet Engine to Use Carbon-Fiber Composites

It used to take four engines to power an aircraft on a long-distance flight. The GE90 helped change all that. With just one GE90 per wing, a Boeing 777 can travel nearly halfway around the globe without refueling. To make that possible, researchers experimented for decades with new materials that would reduce the engine’s weight and fuel burn. Their ingenuity is most visible in the GE90’s four-foot-tall fan blades. Made from lightweight and durable carbon-fiber composites (CFCs), the blades — one of which resides in the Museum of Modern Art — are critical to the GE90’s record-setting thrust. Composite fan blades have since helped improve fuel efficiency in the GEnx, CFM LEAP,* and GE9X engines.

CFM LEAP: First Use of CMCs and 3-D Printed Parts in a Commercial Jet Engine

The CFM LEAP engine is 15% more fuel-efficient than its predecessor, the CFM56. Its performance gains come in part from revolutionary materials: It was the first widely deployed commercial engine to incorporate ceramic matrix composites (CMCs) and 3D-printed parts in the hot section. Developed in Niskayuna and used in the engine’s turbine shroud, CMCs are twice as strong as metal, at a third the weight. 3D printing enables the production of lighter, more durable, and more complex parts, such as the LEAP’s fuel nozzle injector.

First Test of High-Power, High-Voltage Hybrid Electric Systems at Simulated Altitude

In partnership with NASA, GE Aerospace engineers completed the world’s first test, in 2022, of a megawatt-class and multi-kilovolt hybrid electric propulsion system in altitude conditions that simulate single-aisle commercial flight. Researchers in Niskayuna had spent years prior to the test developing the power system. Their biggest challenge: managing power and voltage at altitude. Air is a natural insulator, and the higher you fly, the less of it there is, which increases the risk of arcs. Component by component, GE Aerospace researchers are working to help develop a hybrid electric propulsion system that performs reliably in flight.

First Hypersonic Dual-Mode Ramjet Rig Test with Rotating Detonation Combustion in a Supersonic Flow Stream

Flying from New York to Los Angeles in less than an hour sounds like science fiction. But engineers are closing in on hypersonic flight — that is, flying at five times the speed of sound. Last year, GE Aerospace took a giant leap toward that vision by successfully demonstrating a hypersonic dual-mode ramjet. In a ramjet, air is compressed for combustion by specially engineered inlets rather than traditional compressors and turbines. To equip the ramjet for hypersonic speed, GE Aerospace researchers developed a rotating detonation combustion system, which burns fuel in waves of small, controlled explosions for higher thrust and efficiency. Advancing from concept to test in less than 11 months, the engine showed robust operation and triple the airflow of legacy hypersonic technology demonstrators.

One hundred and twenty-five years on, GE Aerospace researchers are just getting started. Today the Niskayuna facility is the epicenter of GE Aerospace’s high-risk, high-payoff investigations into emerging technologies. Its vantage point — at the nexus between the lab and the hangar — continues to illuminate the next frontiers in the future of flight.

*The CFM LEAP engine is a product of CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines.