How a GE Aerospace Lean Leader Worked with a Supplier to Solve a Baffling Problem

May 2, 2025 | by Chris Noon

In early 2024, Josh Gregg was trying to solve a “good” problem. A Vermont-based sourcing lean leader for GE Aerospace, Gregg was starting a temporary assignment advising a manufacturing company in northwestern Pennsylvania that makes airfoil components for GE Aerospace’s jet engines. As he quickly discovered, the hardworking outfit was struggling — not with too little work, but too much of it.

“We’d seen demand for CFM LEAP engines absolutely skyrocket,” says Gregg, referring to the high-bypass turbofan engine developed by CFM International, the 50-50 joint venture between GE Aerospace and Safran Aircraft Engines. “We just couldn’t make parts fast enough.”

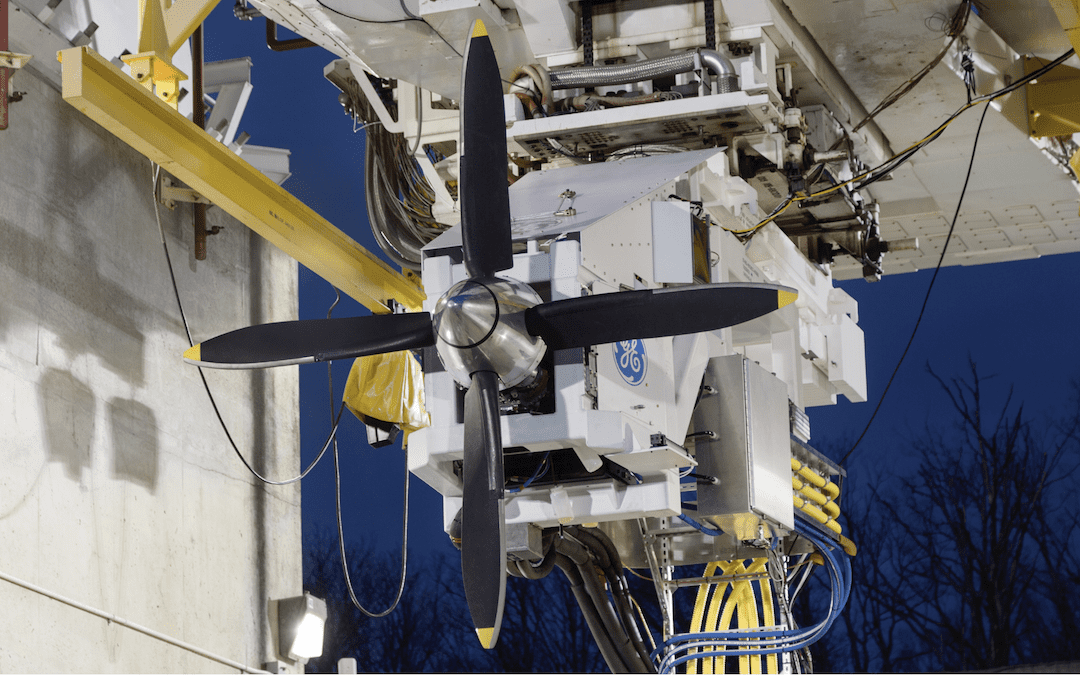

For more than 50 years, the Pennsylvania supplier has sold GE Aerospace parts. Recently, they’ve included nozzle baffles, the nickel alloy parts that distribute cooling air inside the LEAP engine’s fuel nozzles. But the sudden boom in demand for the engine had wrong-footed the venerable fabricator. The cracks were starting to show on their production line, with some minor inefficiencies beginning to feel like real problems.

“You couldn’t boil it down to an equipment, capacity, people, or material issue,” explains Gregg. “It was a mix of everything.” The problems kept coming at the manufacturer’s machinists and managers. “We’d make a fix, and then as soon as we were done, there was another problem,” says Gregg. “The LEAP engine ramp had put them under constant pressure.”

However, over the past year, Gregg has helped the manufacturer eliminate waste and improve its tempo by harnessing FLIGHT DECK, GE Aerospace’s proprietary lean operating model, to drive operational excellence, instill a mindset of continuous improvement, and deliver exceptional value. Since the first quarter of 2024, the manufacturer has more than doubled the weekly supply of nozzle baffles to GE Aerospace and increased deliveries of all parts by more than 80%.

This supplier’s lean turnaround will help GE Aerospace keep pace with rampant demand for the world’s narrowbody engine of choice. Meanwhile, the engine maker and the supplier are moving beyond a simple buyer-seller relationship to become closer and more collaborative partners. “We’ve come such a long way in a short time,” says Gregg.

Forging a Partnership

The Pennsylvania shop has a well-earned reputation for efficiency, quality, and punctuality. “Their schedule attainment is around 95%,” says Gregg, referring to the frequency with which the company meets its production goals. But the new production targets are a tall order for the rural shop.

Fortunately, Gregg could call on more than 20 years of experience in jet engine and gas turbine component manufacturing in his troubleshooting mission. He knew his first job was to win the supplier’s trust. “I wouldn’t want some stranger saying ‘I’m going to fix you’ when they don’t even know what the company’s making,” he says.

So the sourcing lean leader did his homework on the supplier and the baffle-making process. He decided to position himself as a vital go-between, whether it was relaying business-critical messages to his contacts or helping the shop navigate GE Aerospace’s stringent quality approval process. “I tried to pull everybody back to the middle where they need to be,” he says.

One thing he noticed was that the fabricator needed a more methodological approach to problem-solving. The team in the shop would get sidetracked with new problems and leave ongoing problems unresolved. “We needed to get crisp on what the problems were, stay focused, and then fix them,” he says.

But that was easier said than done. The nozzle baffle consists of a single piece of metal, yet making it is a complex job that requires cold forming, welding, brazing, and sealing, all with micromillimeter precision. After going to genba — a Japanese concept that involves analyzing “the place where the work is done” — Gregg found inefficiencies lurking throughout the baffle-making process.

Case in point: The shop team discovered that they were wasting precious time, energy, and materials on an unnecessary job. “We discovered that the machinists were hand-benching all of the braze material off the baffle when it didn’t affect its performance,” explains Gregg. “So we’ve stopped doing that altogether.” Over the long term, eliminating that extra step will save hundreds of square meters of hardware and thousands of hours of painstaking manual labor. Next up, Gregg and the shop team are planning a thorough audit of the supplier’s welding processes.

With FLIGHT DECK’s leaner methods safely embedded, the supplier is finding it a little easier to adapt, improve, and rise to the occasion. “This isn’t a story about a company that wasn’t doing great,” explains Gregg. “It’s about one that has successfully activated FLIGHT DECK in order to accelerate and meet customer demand.”