GE Aviation is well known for being a world-leading provider of jet and turboprop engines and components, but where do we get our start? How is the very first engine in a product line assembled?

"Building an engine for the first time like the GE9X FETT (first engine to test) requires teamwork across the business,” said Lionel Hamilton, program manager in Development Assembly at GE Aviation.

Teams in Engineering, Sourcing and Supply Chain have been flexing their FETT muscles. During the last three years, five new engines were assembled for the first time: Passport (June 2013), LEAP-1A/-1C (September 2013), Adaptive Engine Technology Development (AETD) (October 2013), LEAP-1B (June 2014) and, most recently, the GE9X engine (March 2016).

The teamwork didn’t stop with FETT. Throughout this same three-year period, about 90 development engines were assembled at GE Aviation – marking one of the biggest engine development periods for the business. How do they do it? Watch and learn as Lionel Hamilton walks a student through the process of building a first engine to test.

https://www.youtube.com/watch?v=7wphOlL34hI&feature=youtu.be

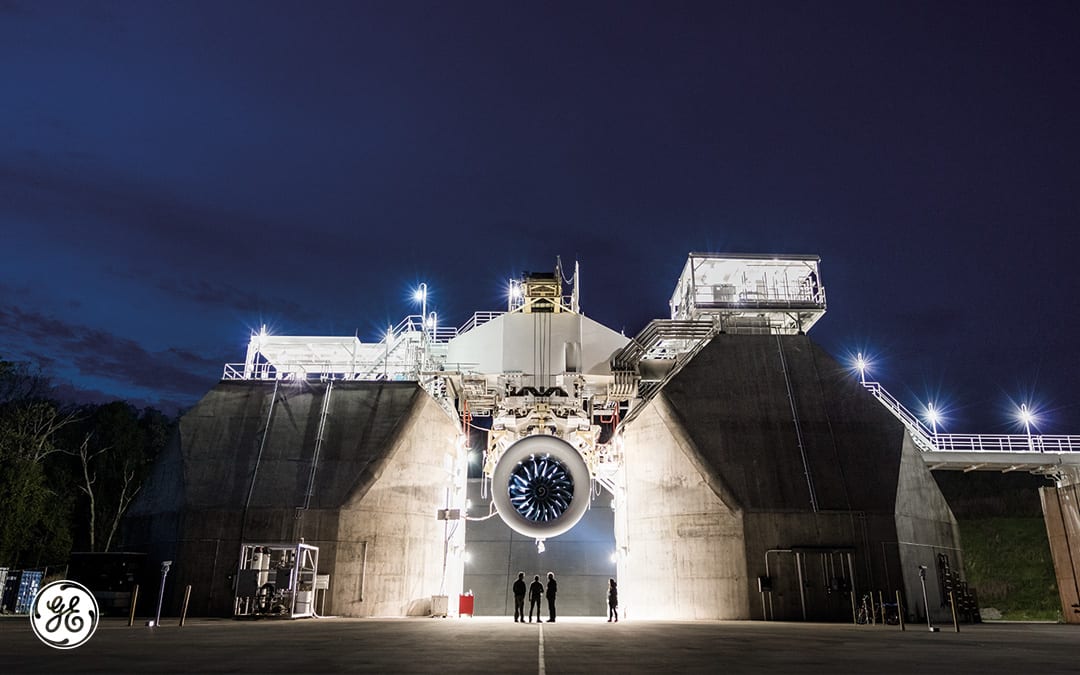

A LEAP-1A in test at GE Aviation's Peebles Testing Operation in Ohio.

A LEAP-1A in test at GE Aviation's Peebles Testing Operation in Ohio.

"Building an engine for the first time like the GE9X FETT (first engine to test) requires teamwork across the business,” said Lionel Hamilton, program manager in Development Assembly at GE Aviation.

Teams in Engineering, Sourcing and Supply Chain have been flexing their FETT muscles. During the last three years, five new engines were assembled for the first time: Passport (June 2013), LEAP-1A/-1C (September 2013), Adaptive Engine Technology Development (AETD) (October 2013), LEAP-1B (June 2014) and, most recently, the GE9X engine (March 2016).

The teamwork didn’t stop with FETT. Throughout this same three-year period, about 90 development engines were assembled at GE Aviation – marking one of the biggest engine development periods for the business. How do they do it? Watch and learn as Lionel Hamilton walks a student through the process of building a first engine to test.

https://www.youtube.com/watch?v=7wphOlL34hI&feature=youtu.be