Building the Future: Bernard Anderson’s Design Vision and Mentorship Shaped Pioneering Engines and GE Leaders

March 25, 2024 | by Dianna Delling

Bernard “Bernie” J. Anderson’s childhood home, a farmhouse near Seattle, was filled with balsa-wood airplanes. As a teen in the 1940s, when he wasn’t watching the skies for World War II airplanes, he was building intricate replicas of propeller-driven military aircraft, which he studied endlessly. His passion for aviation was evident, and so was his gift for engineering.

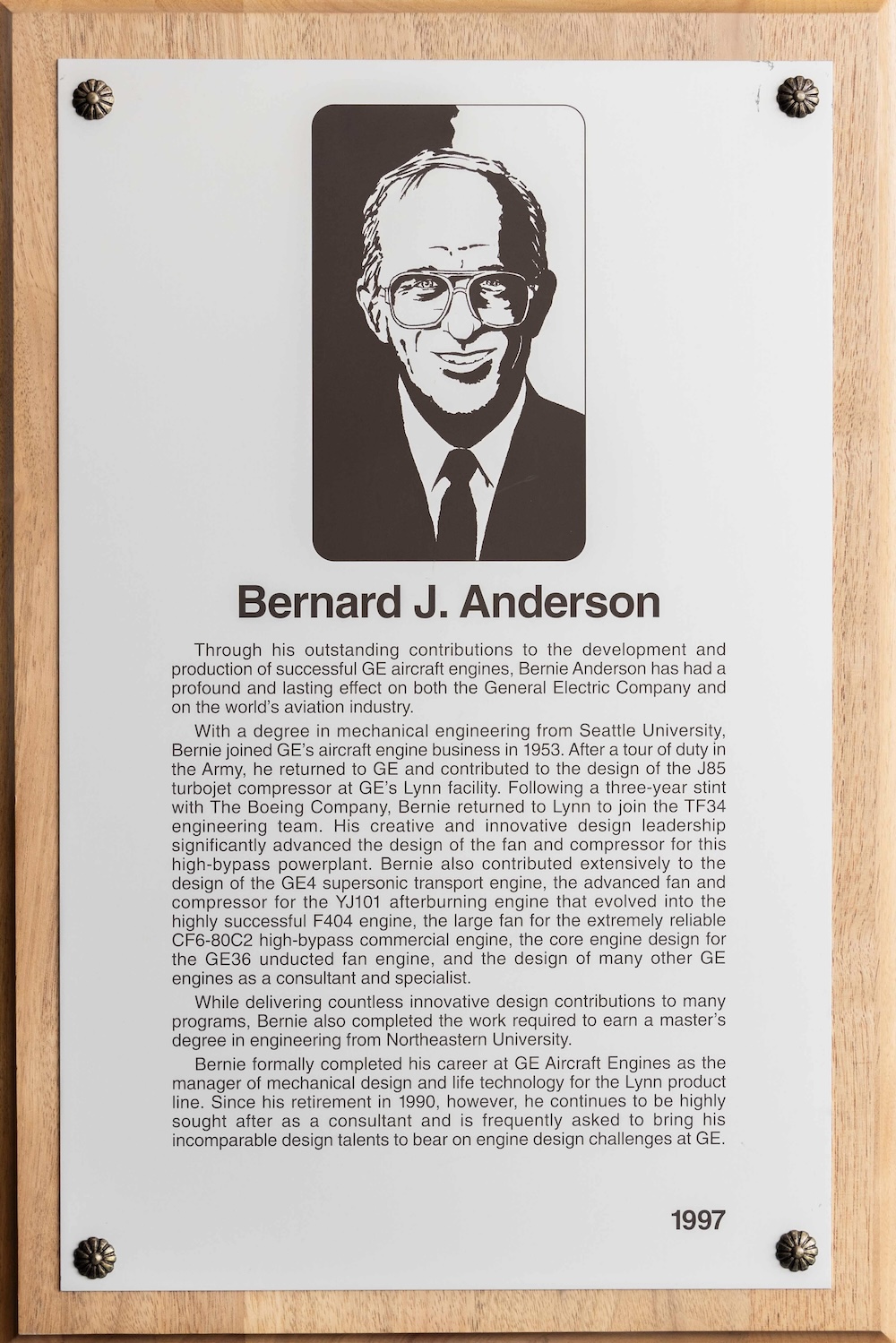

Anderson went on to a nearly 40-year career at GE Aerospace, where, as a mechanical engineer focused on jet engine turbomachinery design, he helped usher in the era of jet-powered aviation. His work on some of the 20th century’s most iconic engines earned him a place in the GE Aerospace Propulsion Hall of Fame. Although Anderson died on December 15, 2023, at 93, he is remembered for his engineering mindset and his mentorship.

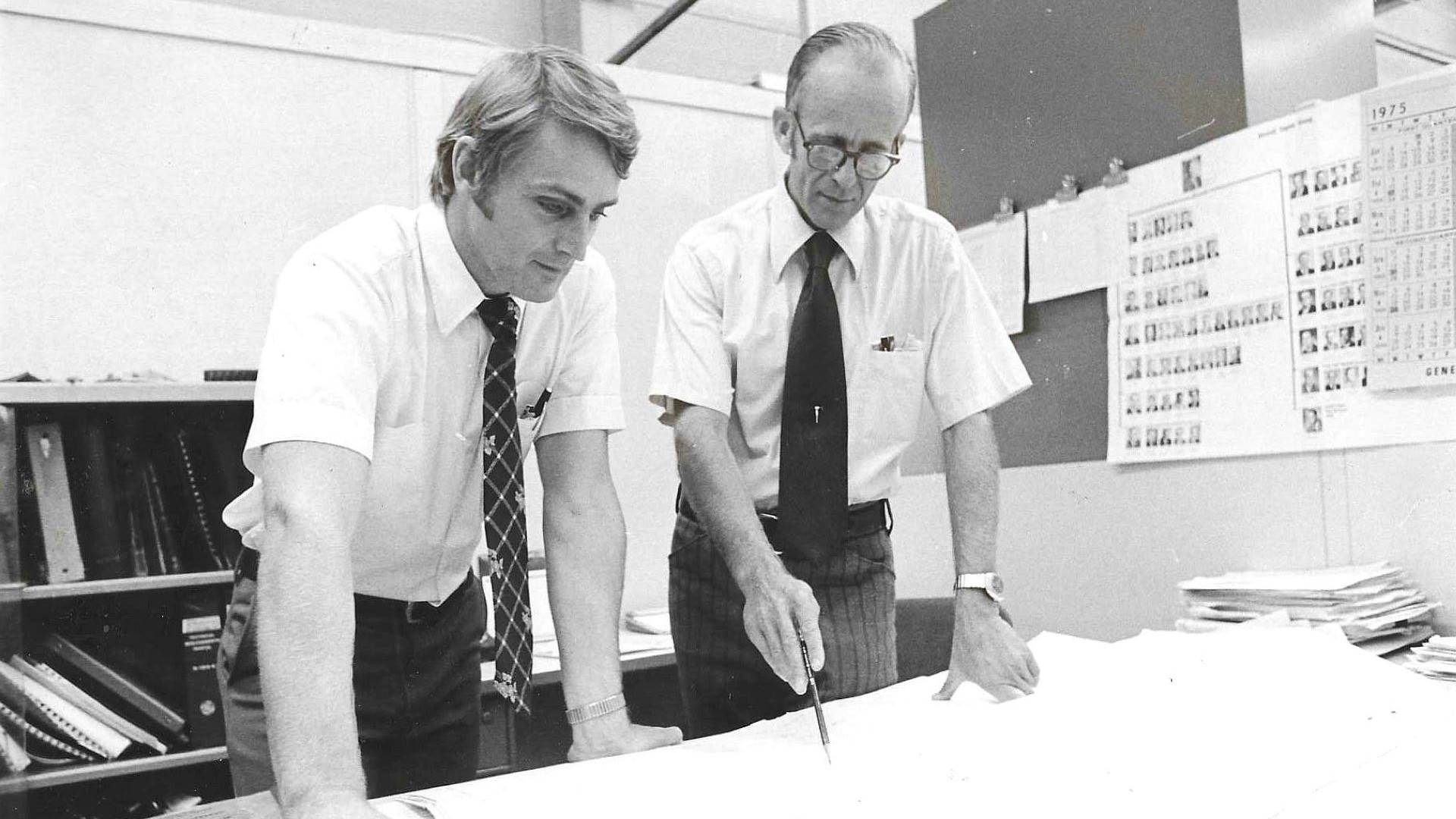

“Bernie was creative and insightful, and he had a sixth sense in mechanical engineering and related disciplines,” says Robert R. Kursmark, a retired chief engineer for engine system design, who worked with Anderson for more than 20 years. “He was sought after by young engineers, like me, looking for a boss who could also be a teacher, mentor, and sponsor.”

Anderson arrived at GE’s aircraft engine business in Lynn, Massachusetts, in 1953, shortly after earning his bachelor’s degree in mechanical engineering from Seattle University. (Later he would study at MIT and Northeastern University to earn his master’s degree.) He remained with the company until his 1990 retirement, with two short breaks to serve in the U.S. Army and for a three-year stint at the Boeing Company.

“He was totally devoted to GE,” says Karl Anderson, Bernie’s eldest son. “My dad was right there, working on the jet engines of the early 1950s, all the way to the huge turbofan engines that propel the Boeing 777 today.”

Bernie launched his career by contributing to the design of GE’s J85 turbojet compressor, the tiny but mighty, highly reliable military engine introduced in 1954. Seventy years later, the J85 is still powering U.S. military aircraft, and it’s expected to be kept in service until at least 2040.

“I had the pleasure of working with Bernie frequently for more than 30 years, despite his location in Lynn, Massachusetts, and mine in Evendale, Ohio,” says James Rhoda, a retired chief engineer and Propulsion Hall of Fame member. “He was truly an engineer’s engineer and used his talent to develop practical solutions to complex problems without a lot of fanfare and self-promotion. I frequently drew on his knowledge by involving him in design reviews of new product designs, and he never disappointed with his technical contributions and diplomatic recommendations.”

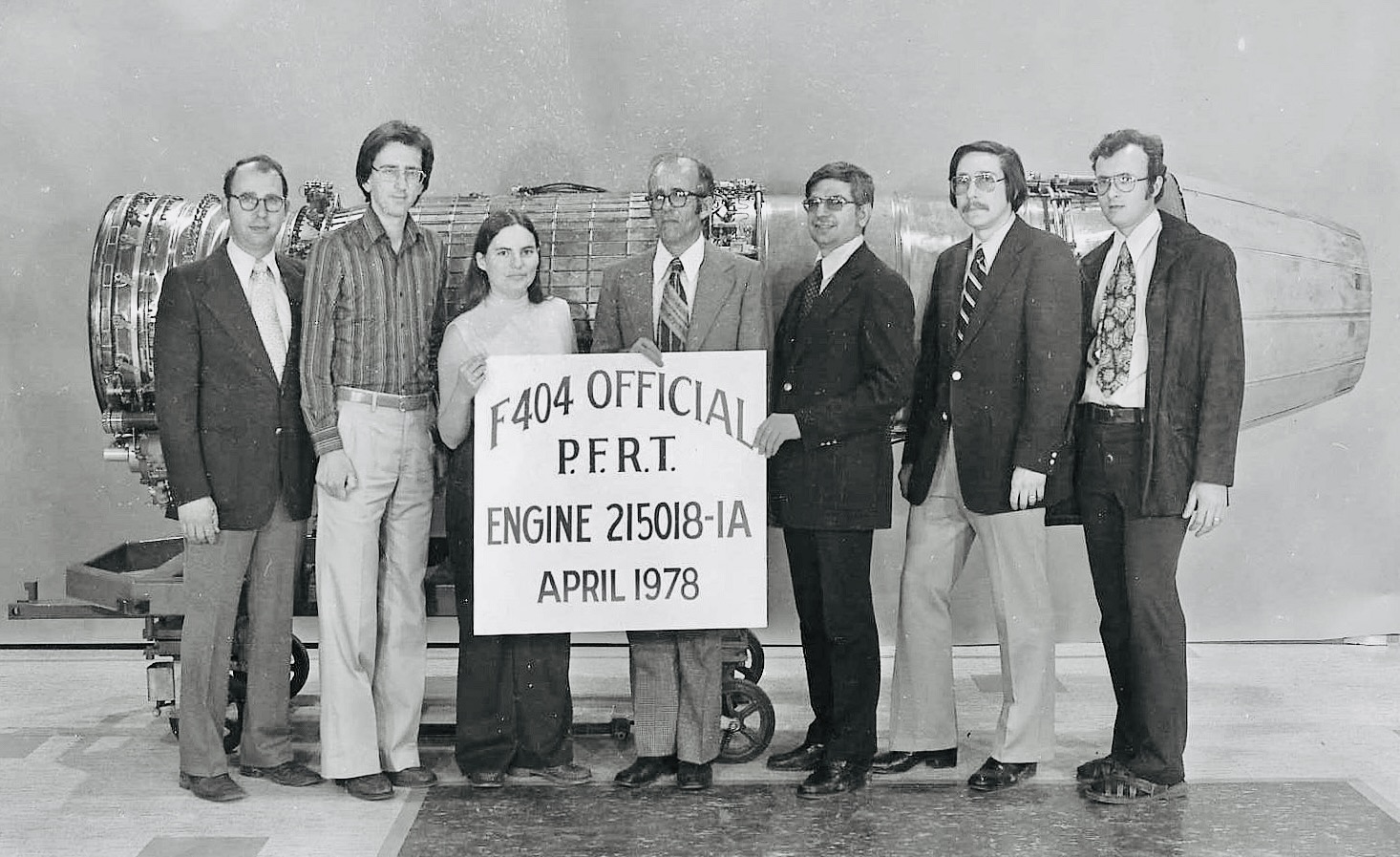

With his signature creativity and leadership, Anderson played a key role in designing the advanced fan and compressor for the TF34, the high-bypass engine used on the U.S. Air Force’s A-10 Thunderbolt II, among other aircraft. He made extensive design contributions to the GE4 supersonic transport engine, as well as the YJ101 afterburning engine, which evolved into one of the most widely used military jet engines in the world, the F404.

“Bernie was a great thinker,” says Jan Schilling, a retired chief engineer for GE Aircraft Engines. “He approached problems wanting to understand the root cause.”

Anderson’s ability to solve difficult design problems made him a valuable member of teams developing new commercial engines as well. He helped develop the fan for the CF6-80C2 high-bypass turbofan, still powering some of the most successful commercial jets in the world and so reliable that it was chosen to power Air Force One. His work on the GE36, the revolutionary unducted fan engine built and tested in the 1980s by CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines, laid the groundwork for technologies now being used in the Revolutionary Innovation for Sustainable Engines (RISE) program, which aims to reduce fuel consumption and carbon emissions by more than 20% from today’s most efficient aircraft engines.

Throughout the years, Anderson always took time to share his knowledge and passion with younger colleagues. Kursmark, who began working with Anderson in 1976, credits him for helping to shape and inspire his own career path. “Bernie was the most influential boss I ever had,” he says. “He taught me what engineering was all about and how to be a great engineer.”

“He was a great listener who valued everyone’s opinion,” says Schilling, who worked under Anderson and was himself a Propulsion Hall of Fame member. “Bernie was an engineer you were proud to work with.”

In his retirement, Anderson was a highly sought-after consultant for GE Aerospace projects. He enjoyed having more time to spend with his family, and he remained active through his late 80s, traveling, running, and playing tennis. He kept his design skills sharp too, building furniture in a backyard woodworking shop.

Anderson is survived by his wife of 68 years, Betty Moore Anderson, who was the love of his life, four children, and many grandchildren.