Turnaround Story: At This Overhaul and Repair Shop in Brazil, FLIGHT DECK Is Driving a Cultural Transformation

August 5, 2025 | by Chris Norris

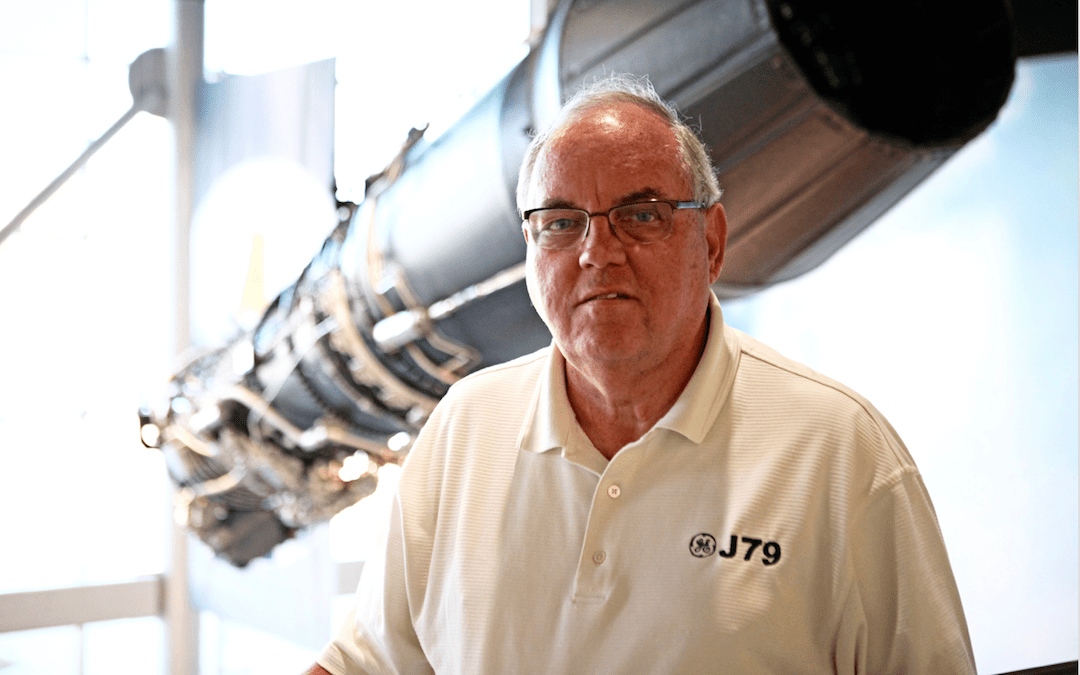

“It’s a system in constant motion,” says Maximiliano Aguiar, senior FLIGHT DECK manager at GE Aerospace’s Celma Overhaul and Repair Shop in Brazil, where the company’s proprietary lean operating model, FLIGHT DECK, is helping to drive operational efficiency and reduce waste. “We use FLIGHT DECK to diagnose how our operational and transactional processes are working and to reveal how they can be improved,” Aguiar continues. “So while it helps us design and build more effective processes, it also gives us the proper tools to manage and improve them over time.”

The Celma Overhaul and Repair Shop was a relatively early adopter of lean principles, bringing a few of them onboard back in 2000 — and for good reason. About 30 international airlines depend on the employees at the Celma site to keep the CFM56* engine, the LEAP* engine, and others operating safely with as little turnround time (TAT) as possible. As part of their journey to drive continuous improvement, the team has used FLIGHT DECK to make several improvements: a 23% TAT reduction in the LEAP test cell since August 2024, a 32% TAT reduction in the CFM56 fan cell line — bringing it down from 68 days in 2023 to 46 days — and a 58% TAT reduction in low-pressure turbine (LPT) blade repair.

“The LPT blade repair was a huge improvement,” says Aguiar, who credits this improvement to FLIGHT DECK and the introduction of “single-piece flow” in the Celma site’s new model cell. At the time, the team was working with a substantial number of parts in what is called WIP (work in process): more than 24,000 parts — as opposed to a standard WIP of 19,000 — resulting in high lead time. “A model cell applies lean tools, concepts, and culture intensively and acts as a ‘role model’ for other cells,” Aguiar explains. “Single-piece flow means that, rather than having a batch process, you send one LPT blade at a time through the entire process: inspection, welding prep, welding, machining, benching, then back to assembly,” which allows the team to balance labor productivity and use of company assets. “It’s a classic lean concept in that it helps us deliver what we need in terms of quantity and quality, without waste or overproduction.”

FLIGHT DECK has also helped the team determine new standards for each individual line. “For example, we have three slots before inducting an engine in the shop floor, so if we see four slots, we know it’s abnormal,” Aguiar says. “And with that visibility, we can find and fix issues much more quickly. We know that we have the necessary parts, tooling, and material on the assembly line, with neither shortages nor excess. This is true at the shop-floor level, at the cell level, and in all other areas.”

Putting in the Time Pays Off

In the CFM56 fan cell, leaders applied FLIGHT DECK Fundamentals to identify delays in final assembly using value stream mapping (VSM) to construct a new model cell for the CFM56 engine line. “It was an 18-month journey from the first VSM to the last six months of achieving sustained results,” Aguiar says.

While the Celma facility had applied lean principles to the entire plant by 2015, it’s been on a journey of continuous improvement since then, which has yielded greater dividends as FLIGHT DECK continues to circulate throughout the plant’s bloodstream. The LPT blade TAT improvement came through decades of lean-guided evolution in the daily life of the plant. This means running kaizen events on the shop floor at least once a week, going to genba (leanspeak for the place where the work happens), and, in partnership with Shingijutsu, holding more intensive kaizen events, which brings a more rigorous, highly focused attention to improving processes, helps company leaders to develop, and strengthens teamwork.

All Fundamentals of FLIGHT DECK can obscure what Aguiar calls “the secret sauce” of the operating model, which is people. “It’s the people that we’re training and how they are always looking for opportunities to improve.”

“It’s really a cultural transformation,” explains Plant Manager Julio Talon. “Our employees understand that they have opportunities to improve every day. I see them on the shop floor, and their engagement level is just so high. They understand how important the smallest part of the process is to the overall result. And this makes them feel more empowered, especially when they hear from our CEO how important FLIGHT DECK has been to the company.”

“It always feels good to go to genba and be with the people,” Aguiar says. “To know they feel proud of the work they’re doing. To see people from one cell line get inspired by another cell line’s kaizens and seek ways to improve what they’re doing too. FLIGHT DECK reshapes the whole environment. And at this point, it’s almost hard to stop.”

*The CFM56 and LEAP engines are manufactured by CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines.