Big Things in Small Packages: GE Aerospace Teams with Kratos to Build Small Engines for Collaborative Combat Aircraft

August 18, 2025 | by Chris Norris

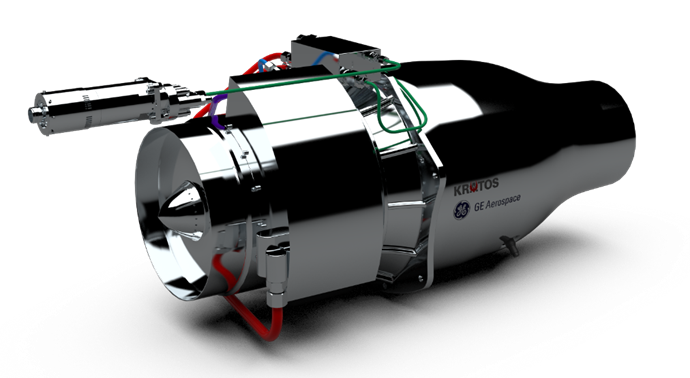

In early June, GE Aerospace’s Defense & Systems division signed a formal teaming agreement with Kratos Defense & Security Solutions to put performance and affordability into a small and mighty package: the high-thrust turbofan propulsion systems for the next generation of unmanned aerial vehicles (UAVs). The latest such engine — able to deliver 1,500 pounds of thrust — belongs to a class of small engines destined for use in reusable or expendable Collaborative Combat Aircraft (CCA). Through this new partnership, a team from GE Aerospace’s Edison Works is learning to apply 75 years of jet propulsion know-how in a novel way.

The new small engines build on projects that Edison Works began with Kratos in 2023 — initially with the GEK800 engine, which provides 800 pounds of thrust for cruise missiles. Along with its 20 years of experience producing small, affordable engines for unmanned aircraft systems, drones, and missile platforms, Kratos brings a different scale and tempo. “Kratos is fast, and they have much, much more flexibility,” said Mark Rettig, Edison Works’ vice president and general manager of Edison Works Advanced Programs, speaking at a briefing with three colleagues from Edison Works in early June, alongside Stacey Rock, Kratos’ president of turbine technologies. “Our teams came together to evolve an optimized design process.”

This process would merge expertise in two very different kinds of businesses. “Developing a high-end, highly capable, highly survivable platform that needs to survive thousands of cycles — our company is actually really good at that,” said Edison Works’ general manager, Steve “Doogie” Russell. “But a low-cost model for something that only has to survive a couple of cycles, or even hours? That’s completely different.”

Had Edison Works merely scaled down its existing operation, Russell said, it would be unlikely to hit the cost and performance targets these unique small engines need. As Rock explained it: “Taking a large engine and scaling down is very difficult because of design, tolerances, and manufacturing. On the other end of the spectrum, building a small turbo jet and scaling it up into a world-class performance turbofan engine for a cruise missile — that’s also very difficult. This team’s really hit a sweet spot.”

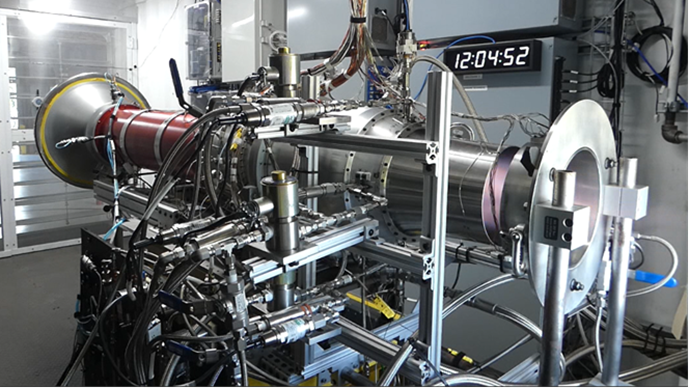

Several years ago, Kratos began developing what would eventually become the GEK800 engine — initially with partial funding from the Defense Advanced Research Projects Agency (DARPA), the U.S. Air Force, and the U.S. Navy — for the advanced cruise missile market. “We are good at going fast and being affordable,” Rock said at the briefing. “And there weren’t a large number of engines available in that class for these systems.”

The partnership with Edison Works began as a David-and-Goliath alliance. “We’ve always seen ourselves as a potential disruptor, but we needed help with production, with long-term agreements with suppliers, all of these things where we didn’t have demonstrated capability,” Rock continued. While the Edison Works team brings a deep legacy of designing gas turbines, this has been mostly for aircraft that carry humans. “We’re really good at flying families across the Atlantic,” said Rettig. “But it’s really hard to design something exquisite and make it cheap.”

Early on, it became clear that the trick was to hit the low-cost target first and then, Rettig said, “add capabilities as necessary.” Craig Young, Edison Works’ engineering director for small UAV engines, pointed to a mental shift the partnership brought. “The Kratos team has been able to help us think differently about a culture of rapid development,” he said. This summer the GEK800 engine will undergo testing on its fifth build. The first production GEK800 engine will be ready for altitude and ground testing by early next year — the first exemplar of this best-of-both-worlds approach.

“Everybody wanted an affordable engine, but they also wanted one that performed better than the current state of the art,” Kratos’ Rock said. In fitting this bill, the GEK800 engine also provides a scalable architecture. “It forms the basis of an entire family of strike engines Kratos and GE Aerospace will produce together,” he added.

The GEK1500 engine, the 1,500-pound-thrust version of the GEK800 engine, is on track for a demo in 2026. And as the Edison Works–Kratos team continues to move quickly from development to demo, these initial designs will be able to expand into a whole range of CCA-type vehicles. “This is where the partnership is headed,” said Rettig. “There is more scalability opportunity in this particular architecture, and we’ve got two engines under development.”

As the Air Force and the Department of Defense express a growing interest in using uncrewed CCAs as “wingmen” to manned fighters, Edison Works and Kratos have developed a resourceful operation to provide them with propulsion.

“GE Aerospace brings a wealth of data and knowledge. Kratos brings an incredible design process, speed, and risk tolerance,” said Edison Works’ Young, summing up the new relationship. “You put those two together and that’s a tremendous competitive advantage.”