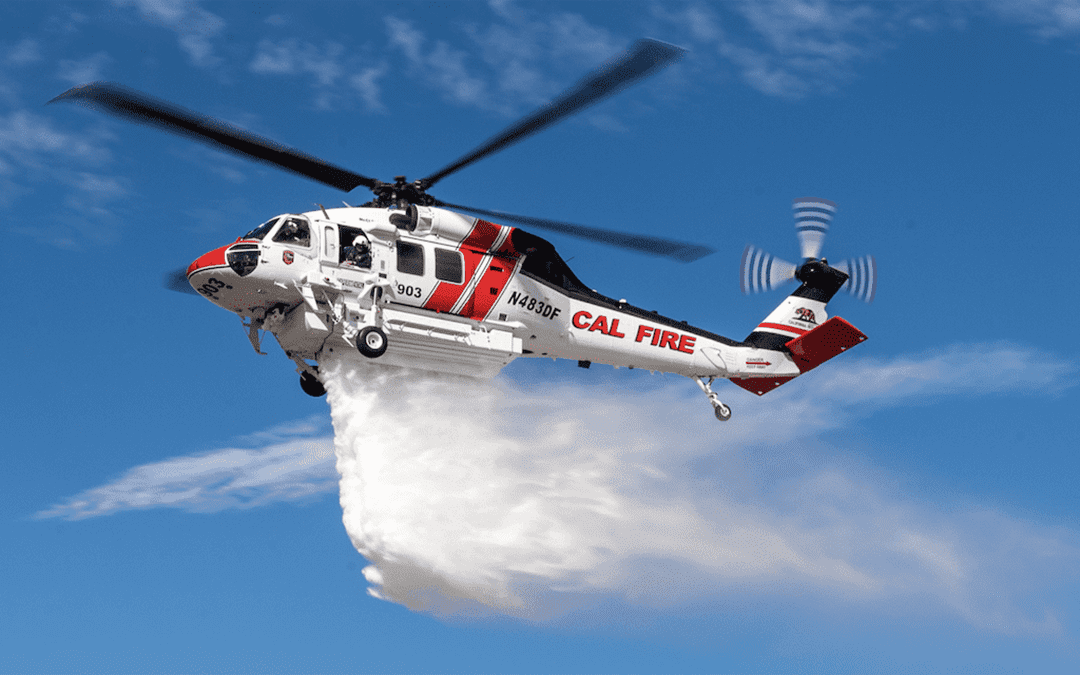

Right now, there are approximately 950,000 people in the sky, lifted by engines made with technology by GE Aerospace and our joint venture partners. What does it take to keep all these flights moving? Behind each successful take-off is an entire network of GE Aerospace experts embedded in hangars and airline hubs, working seamlessly with airline customers to make sure each aircraft is safe, reliable, and ready to fly.

Today, the global aviation industry is navigating unprecedented challenges with surging demand for travel, intricate supply chain dynamics, and the push for greater efficiency alongside reduced emissions. For air carriers, every grounded aircraft represents lost revenue, disrupted schedules, and disappointed passengers. That’s why GE Aerospace and its partners are continually investing to not just design and manufacture high quality engines, but to also service those engines through their lifecycle. New and expanded Maintenance, Repair and Overhaul (MRO) shops in locations like Wroclaw (Poland) Nantgarw (Wales), and Prestwick (Scotland) are helping to restore engines to prime condition, while embedded GE Aerospace staff provide airlines with tailored on-site aftermarket support as airlines operate GE Aerospace’s engines.

At the heart of this aftermarket support are field service engineers (FSEs) and customer support teams – professionals whose work rarely makes headlines but whose impact is felt on every flight. Integrated directly into airline operations at their hubs in strategic locations, they serve as the invisible link between the aircraft on the runway and the complex machinery that powers them.

Their mission: solve technical challenges before they become problems, keep aircraft engines operating reliably, and ensure that airlines can deliver on their promise to passengers. They may not wear wings on their uniforms, but in many ways, they are the invisible co-pilots on the ground that help keep the world’s airline operations on track.

Supporting engines through their life cycle

At London Heathrow Airport– one of the world’s busiest aviation hubs – field service engineers like Richard Evans are deeply embedded behind the scenes of commercial aviation, part of GE Aerospace’s dedicated aftermarket support around the world for engines like the GE90, GEnx and CFM LEAP. Part of a global team of 170 engineers working hand in hand with airline partners across more than 30 countries, it’s a unique role in the industry that’s both highly technical and deeply human. On one hand, FSEs like Richard Evans draw on their vast engineering expertise to help troubleshoot issues, analyze reliability trends and ensure the engines provide the performance demanded by the flight crew on every flight. On the other, they work side by side with airline engineering staff, building trust, anticipating needs, and becoming indispensable partners in the daily rhythm of operations.

“Here at Heathrow, we’re the on-site ambassadors of GE Aerospace to British Airways,” says Richard. “These airlines have complex fleets with tight schedules and turnaround times, where every moment counts. Their top priority is keeping planes in the air and minimizing unplanned ground time. AOG (‘Aircraft on Ground’) situations cause significant disruptions for the airline, creating a ripple effect across operations, which often impacts their passengers. An important part of our job is helping to prevent issues that could lead to AOGs or other disruptions, recommending proactive maintenance to preserve stability across their fleet. When problems do arise, we coordinate support to recover the aircraft as quickly as possible.”

Anticipating problems to keep airline operations running smoothly

For Richard, an aerospace engineer by training who has spent nearly two decades working with GE Aerospace, a typical day might begin with a visit to the customer’s Engineering Operations Centre and the powerplant engineering team, to gain insights on any pressing technical issues, and translate reports into a clear picture of which engines need immediate attention, and what can be monitored and maintained over time. Later, amid the buzz of jet engines taking off from Heathrow’s runways, he’ll pore over fresh performance data and analytics outputs, highlighting unusual trends that could point to an emerging engine issue before it has an effect on future operations. Afternoons can require guidance for maintenance decisions, a visit to one of the hangars to oversee an engine borescope inspection, or liaising with global engineering specialists to resolve technical issues for the customer. Richard might finish the day by using all the intelligence gained to refine the FSEs’ maintenance and overhaul forecast, which feeds GE Aerospace’s supply chain and MRO network planning.

Each customer interaction is an opportunity to anticipate a problem before it grounds an aircraft, learn from shared experiences and improve the way airlines are assisted. Utilizing their extensive local, regional and global networks, Richard and his colleagues facilitate engine support and identify new methods to keep airline operations running smoothly.

In Richard’s words: “My FSE colleagues and I are very passionate about what we do, and care about our customers operations, because ultimately their success is our success.” The customer feedback is clear: GE Aerospace’s embedded teams are seen not just as service providers, but as an extension of the airline’s own workforce.

And in turn, this first-hand insight into operational realities is fed back from the airport flightline to build on existing processes, as part of a culture of ‘Kaizen’, or continuous improvement. FLIGHT DECK, GE Aerospace’s proprietary lean operating model, encourages employees to focus on constantly finding better ways to work with partners on improving processes, and the first-hand experience of FSEs is crucial to deliver exceptional customer value. One recent initiative saw FSEs, airline technicians and support teams partner to spend a full day immersed in seeing the engine deep-cleaning 360 Foam Wash process in action at customer sites. The result? Simple tweaks to how airline maintenance teams prepared their tools brought wash times down from twelve hours to eight, a 33% efficiency improvement for the local maintenance program, and a contributor to improved fuel efficiency for airlines.

Together, these two pillars – on-the-ground expertise and industrial investment – form a powerful ecosystem that keeps airlines moving, passengers flying, and aviation advancing.

*CFM56 and LEAP are trademarks of CFM International, a 50/50 joint company between GE Aerospace and Safran Aircraft Engines.