There is one simple concept at the heart of the lean management principles that GE Aerospace has embraced: kaizen, or continuous improvement. The aim is to focus on the customer, operate as one team, and deliver with purpose.

It sounds straightforward, but when the operations you manage are as global and multi-tentacled as they are in a company like GE Aerospace, the path to achieve these objectives can take on many twists and turns. This is where FLIGHT DECK comes in.

Launched in 2024, GE Aerospace’s proprietary lean operating model provides a systematic approach to running the business with the goal of delivering exceptional value as measured through the eyes of its customers. FLIGHT DECK does this by leveraging three key behaviors — respect for people, continuous improvement, and customer-driven — and eight fundamentals: standard work, daily and visual management, value stream management, operating cadences, action planning, problem solving, 5S, and flow/pull. The behaviors shape the mindset and culture; the fundamentals drive the execution.

In 2025, FLIGHT DECK inspired and enabled teams across the company. They came together in the spirit of continuous improvement to solve some of the company’s toughest challenges and better serve its customers through a relentless focus on safety, quality, delivery, and cost (SQDC), always in that order.

These six stories highlight how GE Aerospace teams have activated FLIGHT DECK — tackling problems, finding solutions, and ultimately delivering for customers.

Safety First, Always

Matt Allen, environmental, health, and safety (EHS) leader at GE Aerospace’s engine production facility in Lynn, Massachusetts, got an urgent call from a team member. There was a problem in the engine assembly area: a key overhead crane used daily had to be shut down — immediately — for safety reasons. What happened next turned out to be a great example of the Lynn team using FLIGHT DECK to maintain safety protocols while finding a solution — quickly — that enabled them to keep the engine assembly line open and continue delivering for the customer. “We didn’t miss shipping an engine,” says Bobby Eldridge, a servicer in Lynn’s assembly and test operations section and an executive board member of the IUE-CWA Local 201. Read how they did it here.

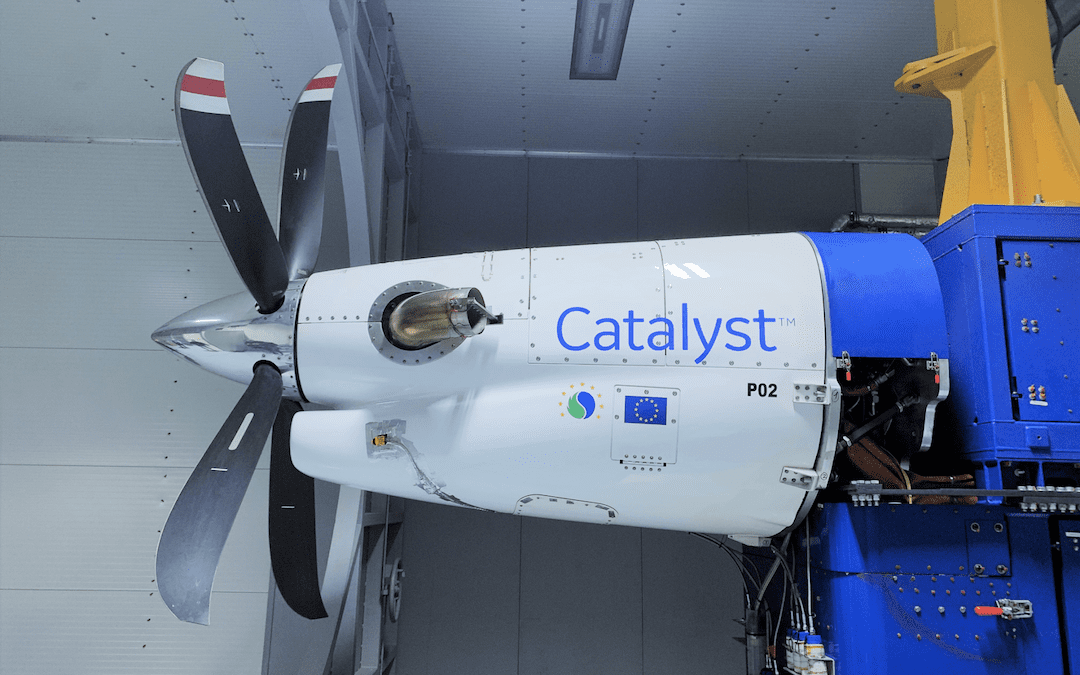

Leveraging Flow Lines to Get Engines Back on Wing

GE Aerospace’s newest On Wing Support (OWS) quick-turn shop, in Shanghai, delivers rapid maintenance services for CFM56-5B/7B* engines and CFM LEAP-1A/1B* engines to customers across China and Asia. But at the start of 2025, “we had a backlog of LEAP engines awaiting repair, and others parked for service,” says Shanghai OWS site leader Wang Tao. To unclog that backlog, Tao and his team pioneered a shift from fixed workstations to a “flow line,” which allows the engines to move through distinct stages, from disassembly to module repair to reassembly. They also introduced the lean concept of heijunka, a “buffer storage” solution that opened floor space for additional engine storage stands to hold disassembled engines while they wait for parts. Now their flow line innovations are being adopted at other OWS sites.

Improving Processes in On Wing Support

Over the past few years, CFM International has boosted production of the LEAP engine to the highest rate ever for a commercial turbofan. But as more LEAP engines have entered service, GE Aerospace’s On Wing Support (OWS) network has had to focus on streamlining the process for a high-pressure turbine (HPT) refresh. It’s a challenge custom-made for FLIGHT DECK. Staff members from all seven OWS sites gathered for a kaizen event, alongside global technical and operational leadership, to redesign their HPT refresh procedures. The result: LEAP output across the OWS network grew by more than 60% over the following year. How did they do it? By getting buy-in from their teams, achieving flow, and unlocking the power of continuous improvement.

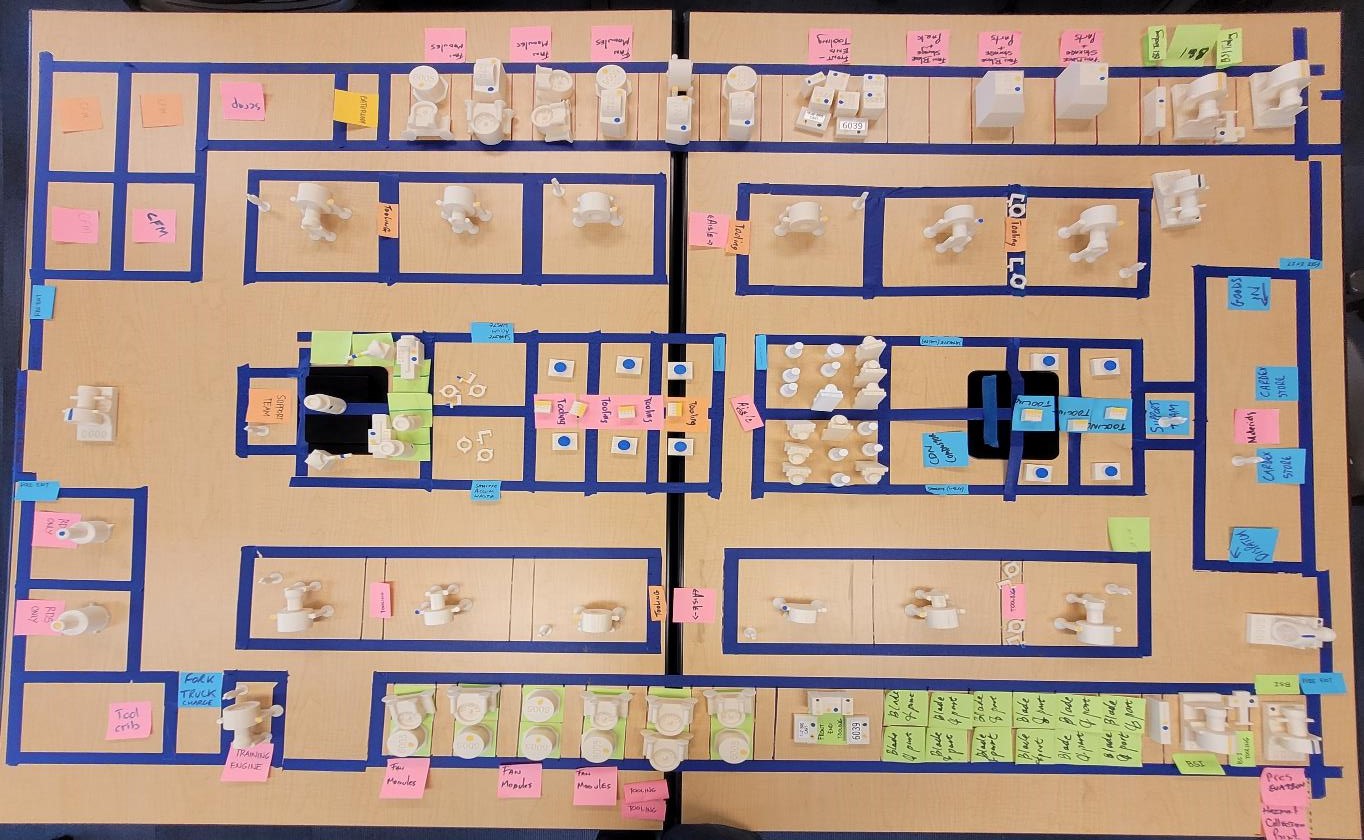

Partnering on Breakthroughs with Our Suppliers

FLIGHT DECK isn’t just being put to use inside GE Aerospace. It’s also being actively used outside the company to improve efficiency and eliminate waste in its massive external supply chain. This past July, Quentin Sweat, a supplier recovery leader, brought together about 40 employees from GE Aerospace and Steel Tool & Engineering, a supplier based in Detroit, for a weeklong shingijutsu kaizen event. “It can be hard to put your hand up and say you want to help,” says Sweat. “But all credit to Steel Tool — their team was ready to collaborate and bought into the FLIGHT DECK fundamentals.” Read how the team at Steel Tool reduced the rework and waste involved in making brazed honeycomb assemblies for turbine blades, which led to a boost in production output.

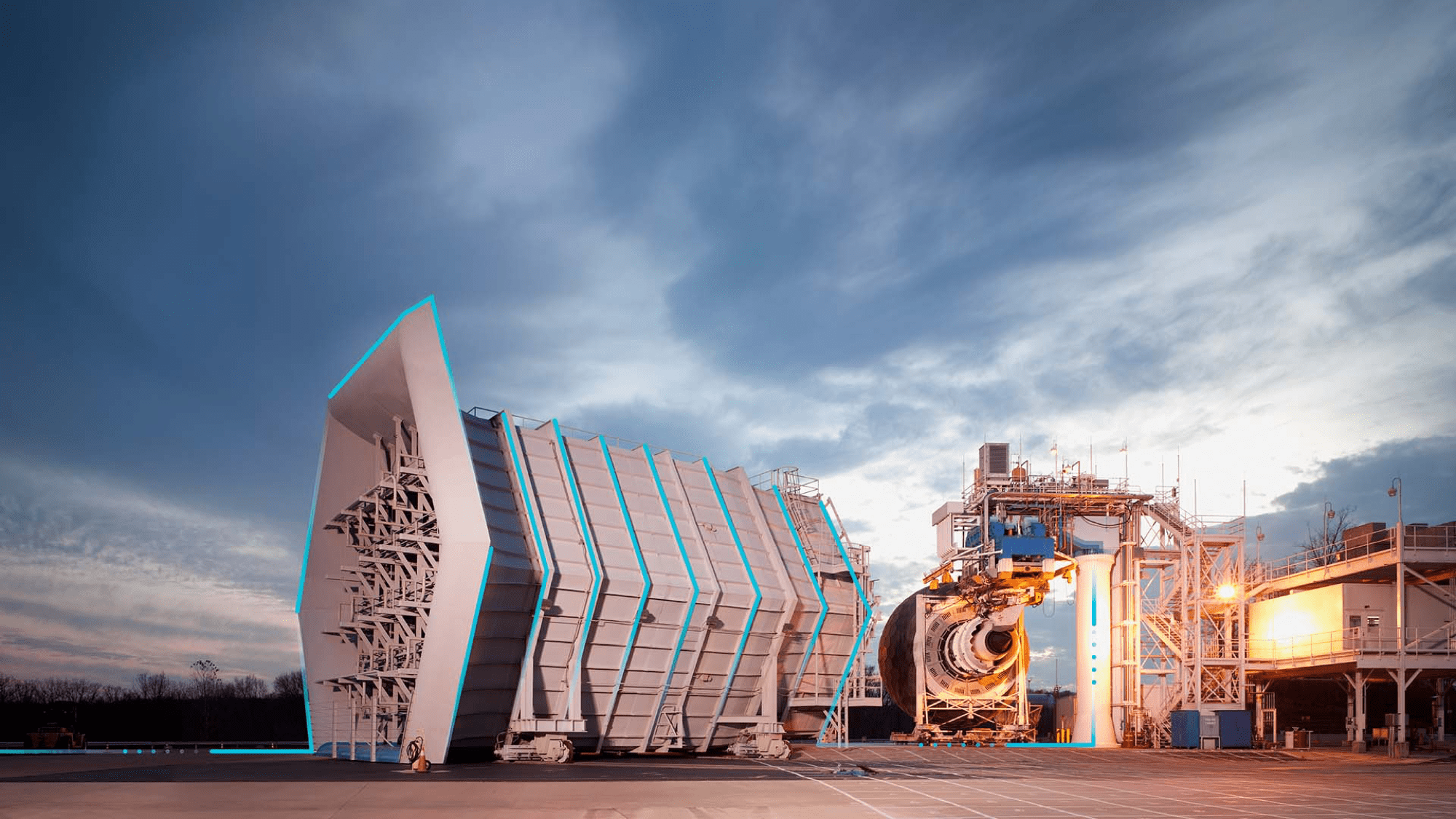

Reducing Turnaround Time for Customers

The Celma Overhaul and Repair Shop in Brazil was an early adopter of lean principles, bringing a few of them onboard back in 2000 — and for good reason. About 30 international airlines depend on the employees at the Celma site to keep the CFM56, LEAP, CF6, and GEnx engines, among others, operating safely with as little turnround time (TAT) as possible. As part of their journey to drive continuous improvement, the team has used FLIGHT DECK to make several improvements: a 23% TAT reduction in the LEAP test cell since August 2024, a 32% TAT reduction in the CFM56 fan cell line — bringing it down from 68 days in 2023 to 46 days — and a 58% TAT reduction in low-pressure turbine (LPT) blade repair.

FLIGHT DECK has helped reshape the facility’s whole culture, says Maximiliano Aguiar, Celma’s senior FLIGHT DECK leader. “And at this point it’s almost hard to stop.” Read about it here.

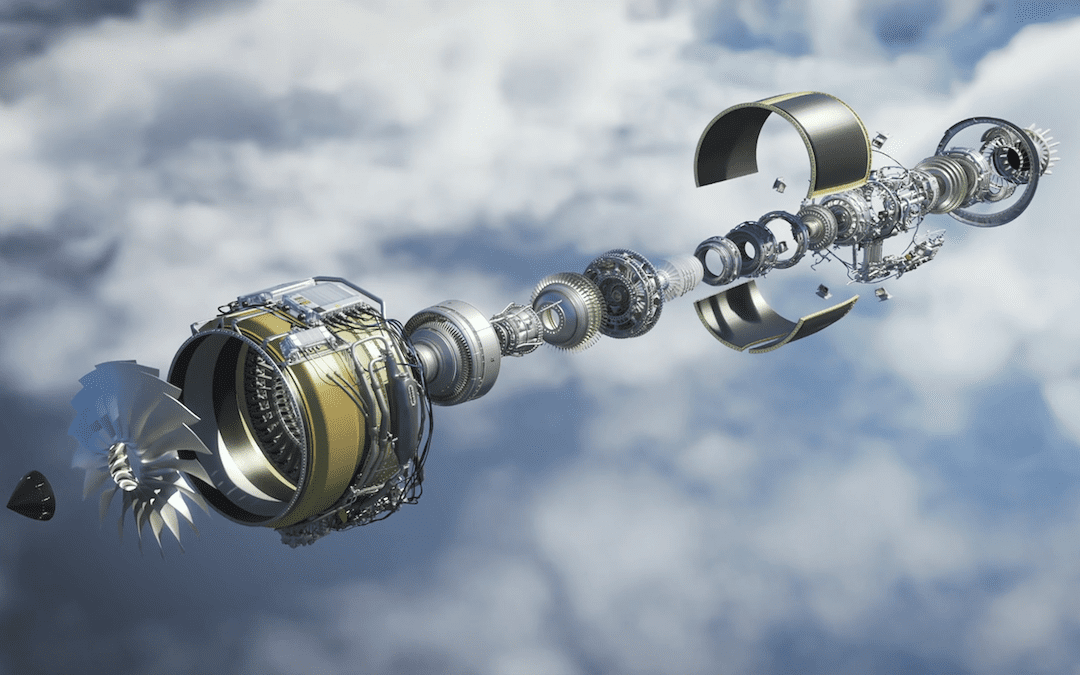

Collaborating to Drive Efficiency

Each year, Avio Aero manufactures more than 18,000 low-pressure turbine (LPT) blades for the GE9X engine program at its site in Cameri, Italy, on a fleet of 50 Colibrium Additive electron beam melting 3D printers, using titanium aluminide alloy powder made by AP&C. “We have a great working relationship with our sister companies,” says Dario Mantegazza, chief additive manufacturing engineer at Avio Aero. But over time they collectively realized that their metal powder handling processes had become too complex. “We saw an opportunity to apply FLIGHT DECK and have a tangible impact,” he says. Read how Mantegazza and a cross-functional, cross-business team went to genba, used value stream mapping, and ultimately streamlined the powder handling process.

* CFM56 and CFM LEAP engines are manufactured by CFM International, a 50-50 joint company between GE Aerospace and Safran Aircraft Engines.